The motor can be used in a wide variety of applications by combining it with a reduction gear(speed reduction).

With the precision processing technology cultivated in watchmaking, Orbray provides geared motors equipped with high-precision gearheads that are quiet and have high transmission efficiency.

* Gearhead is sellable only in combination with motor.

Gearhead Types

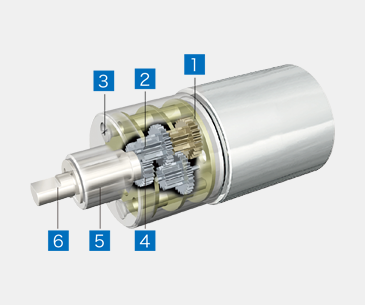

Spur gearhead

- base-plate

- kana (drive sprocket)

- guide

- spur (driven sprocket)

- bearing

- output shaft

- Most popular gearhead

- Gear shaft is aligned in parallel with the output shaft

- No thrust force is generated

- Rotating direction may differ between input shaft and output shaft depending on the stages.

Spur gear: Gear train using spur wheel, relatively simple structured with fewer number of parts, advantage is less mechanical noise.

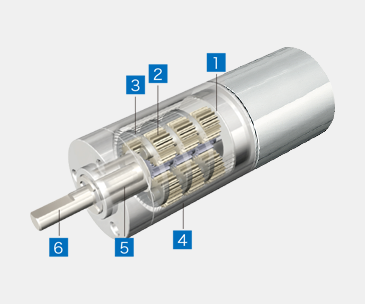

Planetary gearhead

- base-plate

- planetary gear

- career plate

- internal gear

- bearing

- output shaft

- Large reduction ratio can be achieved

- Considerable torque transmission

- Input shaft (motor shaft) and output shaft (gear shaft) are aligned in one straight line.

- Torque is distributed evenly to each planetary gear, so the gear is relatively strong in durability.

Planetary gear: It is called a planetary gear because it orbits around the sun gear. Due to large number of teeth, it is suited for high torque transfer.

By attaching a reduction gear mechanism on the motor output shaft, it can generate high torque/low speed, which motor alone cannot achieve.

Compact motors usually feature high speed, but this speed can be reduced to requested level by combining with a gearhead.

Because torque increases in proportion to gear ratio, high torque can be easily achieved even in a compact motor.

While a gearhead can help generate high torque, it may influence durability and characteristics failure depending on its accuracy.

Using the precision processing technology nurtured in diamond processing/watch part processing, Orbray manufactures and delivers low noise, high efficiency precision gearheads.

Spur Gear

| Products ※1 |

Dia.φ [mm] |

Reduction Ratio (absolute value) |

Number of stage |

Max allowable torque | Efficiency [%] |

Length [mm] |

Weight [g] |

Rotation direction ※2 |

Motor combination | |

|---|---|---|---|---|---|---|---|---|---|---|

| Continous [mNm] |

Intermittent [mNm] |

|||||||||

| SSG10-15 | 10 | 15.40:1 | 3 | 12 | 30 | 73 | 14 | 5.4 | ≠ |

CMS10 series CMS10-13XX with Spur gear CMS10-18XX with Spur gear BMS10 series BMS10-10XX with Spur gear BMS10-18XX with Spur gear |

| SSG10-29 | 29.25:1 | 4 | 12 | 30 | 66 | 16 | 6.2 | = | ||

| SSG10-49 | 48.75:1 | 5 | 12 | 30 | 59 | 18 | 7.0 | ≠ | ||

| SSG10-49 | 72.29:1 | 5 | 12 | 30 | 59 | 18 | 7.0 | ≠ | ||

| SSG10-93 | 93.43:1 | 5 | 12 | 30 | 59 | 18 | 7.0 | ≠ | ||

| SSG10-156 | 155.56:1 | 6 | 12 | 30 | 53 | 20 | 7.9 | = | ||

| SSG10-200 | 199.64:1 | 6 | 12 | 30 | 53 | 20 | 7.9 | = | ||

| SSG10-262 | 261.59:1 | 6 | 12 | 30 | 53 | 20 | 7.9 | = | ||

| SSG12-16 | 12 | 15.79:1 | 3 | 12 | 30 | 73 | 14 | 8.3 | ≠ |

CMS12 series CMS12-15XX with Spur gear CMS12-20XX with Spur gear CMS12-30XX with Spur gear BMS12 series BMS12-15XX with Spur gear BMS12-21XX with Spur gear |

| SSG12-25 | 24.70:1 | 3 | 12 | 30 | 73 | 14 | 8.3 | ≠ | ||

| SSG12-47 | 47.35:1 | 4 | 15 | 30 | 66 | 16 | 9.2 | = | ||

| SSG12-74 | 74.10:1 | 4 | 15 | 30 | 66 | 16 | 9.2 | = | ||

| SSG12-94 | 93.86:1 | 4 | 15 | 30 | 66 | 16 | 9.2 | = | ||

| SSG12-175 | 175.50:1 | 5 | 15 | 30 | 59 | 18 | 10.2 | ≠ | ||

| SSG12-222 | 222.30:1 | 5 | 15 | 30 | 59 | 18 | 10.2 | ≠ | ||

| SSG12-282 | 281.58:1 | 5 | 15 | 30 | 59 | 18 | 10.2 | ≠ | ||

| SSG15-29 | 15 | 29.07:1 | 3 | 15 | 30 | 73 | 9.6 | 8.9 | ≠ | CMS16 series CMS16-23XX with Spur gear CMS16-28XX with Spur gear CMS16-33XX with Spur gear BMS16 series BMS16-20XX with Spur gear BMS16-30XX with Spur gear |

| SSG15-49 | 48.58:1 | 4 | 24 | 60 | 66 | 11.6 | 10.3 | = | ||

| SSG15-71 | 71.35:1 | 4 | 24 | 60 | 66 | 11.6 | 10.3 | = | ||

| SSG15-94 | 93.68:1 | 4 | 24 | 60 | 66 | 11.6 | 10.3 | = | ||

| SSG15-152 | 152.2:1 | 5 | 24 | 60 | 59 | 13.6 | 10.3 | = | ||

| SSG15-198 | 198.06:1 | 5 | 24 | 60 | 59 | 13.6 | 11.5 | ≠ | ||

| SSG15-302 | 301.84:1 | 5 | 24 | 60 | 59 | 13.6 | 10.3 | ≠ | ||

| SSG15-438 | 438.31:1 | 6 | 24 | 60 | 53 | 15.6 | 12.9 | = | ||

| SSG15-638 | 638.18:1 | 6 | 24 | 60 | 53 | 15.6 | 12.9 | = | ||

Planetary Gear

| Products ※1 |

Dia.φ [mm] |

Reduction Ratio (absolute value) |

Number of stage |

Max allowable torque | Efficiency [%] |

Length [mm] |

Weight [g] |

Rotation direction ※2 |

Motor combination | |

|---|---|---|---|---|---|---|---|---|---|---|

|

Continous |

Intermittent [mNm] |

|||||||||

| SPG04-4.3 | 4 | 4.29:1 | 1 | TBD | TBD | 85 | 6.6 | 0.5 | = | BMN04-08XX with Planetary MIM gear |

| SPG04-18 | 18.37:1 | 2 | TBD | TBD | 72 | 7.8 | 0.6 | = | ||

| SPG04-79 | 78.72:1 | 3 | TBD | TBD | 61 | 9.0 | 0.7 | = | ||

| SPG04-337 | 337.36:1 | 4 | TBD | TBD | 52 | 10.2 | 0.8 | = | ||

| SPG07-4.7 | 7 | 4.71:1 | 1 | 10 | 20 | 85 | 7.4 | 2 | = | CMS07-17XX with Planetary gear BMN07-12XX with Planetary gear |

| SPG07-22 | 22.22:1 | 2 | 10 | 20 | 85 | 7.4 | 2 | = | ||

| SPG07-105 | 104.77:1 | 3 | 10 | 20 | 61 | 11.8 | 3 | = | ||

| SPG07-494 | 493.93:1 | 4 | 10 | 20 | 52 | 14.1 | 3.5 | = | ||

| SPG10-3.6 | 10 | 3.60:1 | 1 | 50 | 100 | 85 | 10.5 | 5.8 | = | CMS10 series CMS10-13XX with Planetary gear CMS10-18XX with Planetary gear BMS10 series BMS10-10XX with Planetary gear BMS10-18XX with Planetary gear |

| SPG10-4.7 | 4.70:1 | 1 | 50 | 100 | 85 | 10.5 | 5.8 | = | ||

| SPG10-13 | 12.96:1 | 2 | 50 | 100 | 72 | 13.5 | 7.1 | = | ||

| SPG10-22 | 22.22:1 | 2 | 50 | 100 | 72 | 13.5 | 7.1 | = | ||

| SPG10-47 | 46.66:1 | 3 | 50 | 100 | 61 | 16.5 | 8.4 | = | ||

| SPG10-61 | 61.10:1 | 3 | 50 | 100 | 61 | 16.5 | 8.4 | = | ||

| SPG10-80 | 80.01:1 | 3 | 50 | 100 | 61 | 16.5 | 8.4 | = | ||

| SPG10-105 | 104.77:1 | 3 | 50 | 100 | 61 | 16.5 | 8.4 | = | ||

| SPG10-168 | 167.96:1 | 4 | 50 | 100 | 52 | 19.6 | 9.7 | = | ||

| SPG10-220 | 219.95:1 | 4 | 50 | 100 | 52 | 19.6 | 9.7 | = | ||

| SPG10-288 | 288.03:1 | 4 | 50 | 100 | 52 | 19.6 | 9.7 | = | ||

| SPG10-377 | 377.18:1 | 4 | 50 | 100 | 52 | 19.6 | 9.7 | = | ||

| SPG10-494 | 493.93:1 | 4 | 50 | 100 | 52 | 19.6 | 9.7 | = | ||

| SPG12-3.5 | 12 | 3.50:1 | 1 | 100 | 200 | 85 | 14.2 | 11.6 | = |

CMS12 series CMS12-15XX with Planetary gear CMS12-20XX with Planetary gear CMS12-30XX with Planetary gear BMS12 series BMS12-15XX with Planetary gear BMS12-21XX with Planetary gear |

| SPG12-4.8 | 4.75:1 | 1 | 100 | 200 | 85 | 14.2 | 11.6 | = | ||

| SPG12-12 | 12.25:1 | 2 | 100 | 200 | 72 | 18 | 14.1 | = | ||

| SPG12-23 | 22.56:1 | 2 | 100 | 200 | 72 | 18 | 14.1 | = | ||

| SPG12-43 | 42.88:1 | 3 | 100 | 200 | 61 | 21.8 | 16.6 | = | ||

| SPG12-58 | 58.19:1 | 3 | 100 | 200 | 61 | 21.8 | 16.6 | = | ||

| SPG12-79 | 78.97:1 | 3 | 100 | 200 | 61 | 21.8 | 16.6 | = | ||

| SPG12-107 | 107.17:1 | 3 | 100 | 200 | 61 | 21.8 | 16.6 | = | ||

| SPG12-150 | 150.06:1 | 4 | 100 | 200 | 52 | 25.7 | 19.1 | = | ||

| SPG12-204 | 203.66:1 | 4 | 100 | 200 | 52 | 25.7 | 19.1 | = | ||

| SPG12-375 | 375.10:1 | 4 | 100 | 200 | 52 | 25.7 | 19.1 | = | ||

| SPG12-509 | 509.07:1 | 4 | 100 | 200 | 52 | 25.7 | 19.1 | = | ||

| SPG16-3.6 | 16 | 3.60:1 | 1 | 200 | 400 | 85 | 15.3 | 20 | = |

CMS16 series CMS16-23XX with Planetary gear CMS16-28XX with Planetary gear CMS16-33XX with Planetary gear BMS16 series BMS16-20XX with Planetary gear BMS16-30XX with Planetary gear |

| SPG16-4.7 | 4.71:1 | 1 | 200 | 400 | 85 | 15.3 | 20 | = | ||

| SPG16-13 | 12.96:1 | 2 | 200 | 400 | 72 | 19.5 | 24.5 | = | ||

| SPG16-22 | 22.22:1 | 2 | 200 | 400 | 72 | 19.5 | 24.5 | = | ||

| SPG16-47 | 46.66:1 | 3 | 200 | 400 | 61 | 23.7 | 29 | = | ||

| SPG16-61 | 61.10:1 | 3 | 200 | 400 | 61 | 23.7 | 29 | = | ||

| SPG16-80 | 80.01:1 | 3 | 200 | 400 | 61 | 23.7 | 29 | = | ||

| SPG16-105 | 104.77:1 | 3 | 200 | 400 | 61 | 23.7 | 29 | = | ||

| SPG16-168 | 167.96:1 | 4 | 200 | 400 | 52 | 28 | 33.5 | = | ||

| SPG16-220 | 219.95:1 | 4 | 200 | 400 | 52 | 28 | 33.5 | = | ||

| SPG16-288 | 288.03:1 | 4 | 200 | 400 | 52 | 28 | 33.5 | = | ||

| SPG16-377 | 377.18:1 | 4 | 200 | 400 | 52 | 28 | 33.5 | = | ||

| SPG16-493 | 493.93:1 | 4 | 200 | 400 | 52 | 28 | 33.5 | = | ||

| PG22-4 | 22 | 4.00:1 | 1 | 49 | 74 | 85 | 13.1 | 30 | = | |

| PG22-16 | 16.00:1 | 2 | 74 | 110 | 72 | 16.2 | 35 | = | ||

| PG22-24 | 24.00:1 | 2 | 74 | 110 | 72 | 16.2 | 35 | = | ||

| PG22-64 | 64.00:1 | 3 | 98 | 147 | 61 | 19.3 | 40 | = | ||

| PG22-96 | 96.00:1 | 3 | 98 | 147 | 61 | 19.3 | 40 | = | ||

| PG22-144 | 144.00:1 | 3 | 98 | 147 | 61 | 19.3 | 40 | = | ||

| PG22-256 | 256.00:1 | 4 | 123 | 184 | 52 | 22.4 | 45 | = | ||

| PG22-384 | 384.00:1 | 4 | 196 | 294 | 52 | 22.4 | 45 | = | ||

| PG22-576 | 576.00:1 | 4 | 294 | 392 | 52 | 22.4 | 45 | = | ||

| PG22-864 | 864.00:1 | 4 | 392 | 588 | 52 | 22.4 | 45 | = | ||

| TR22-20 | 22 | 19.91:1 | 2 | 3,000 | 4,000 | 72 | 33.4 | 70 | = | CMS16 series B4S22-32XX with Planetary gear |

| TR22-112 | 111.52:1 | 3 | 3,000 | 4,000 | 61 | 39.6 | 80 | = | ||

| TR22-397 | 396.55:1 | 4 | 3,000 | 4,000 | 52 | 45.8 | 90 | = | ||

※1 RED LETTERS:Non-standard gear

※2 Rotation direction…

=:The same rotation direction as the motor axis

≠:Opposite rotation direction from the motor axis