Metallize

Metallized fibers are an essential component in the manufacturing of Butterfly Style and Optical Pump Modules. The Metallized Fiber is needed to solder or join the fiber onto the substrates present within the LD Modules.

We also have the ability to terminate a connector on the opposite end of the Metallized Fiber. We can also manufacture the fiber end face into a flat, angled or lensed type.

Etching

Fiber etching is an effective technique to miniaturize the OD size of the fiber to be used in high density optical device applications.

Space saving of existing products can be expected by making the fiber cladding diameters more tapered and narrowing the fiber array pitch for bundle fiber applications.

We can manufacture in the order of a few micrometers and we offer a wide range of optimal approaches for existing connection technologies.

AR Coating

We can also apply an AR (Anti-Reflection) Coating on the surface of fibers, lenses and other optical elements to reduce reflection and optical loss.

Bundle

Bundle fiber is a connection technology that bundles multiple etched fibers and inserts them into a large core ferrule.

By inserting the fiber into a bundle, it becomes easy to change the fiber destination by connecting various wavelength bands and making it into a single bundled multi-core connector. The core pitch can be adjusted by using the fiber etching technology.

We offer 3, 4 and 7 cores typically but would consider other core options as well.

Collimator and Focuser

The Collimator and Focuser is an optical component that parallelizes and focuses the light by spherical, aspherical lens or fiber tip processing.

Custom designs are also available based on your beam diameter requirement and optical design.

We also offer AR Coating and Metallization.

2 Row (Cascade)

A two stage cascade is a technique used to assemble rows of fiber in two or more rows in an array.

The array products position the optical fiber cores with precision and accuracy within the V-Groove Blocks in two or more horizontal rows by an ultra precision processing technology. The process requires accuracy on a submicron level in order to reduce the connection loss.

With Glass Capillary

Glass Capillaries are essential components for the manufacture of Optical Coherent Devices and their connection with SiP (Silicon Photonics). We can provide custom shapes similar to ferrule dimensions with two ID Cores and D Cuts.

Borosilicate Glass is the standard material used but other materials and details can also be discussed and provided.

With Isolator

The optical isolator is an optical component which allows the transmission of light in only one direction. It is typically used to prevent unwanted feedback into a laser cavity or LD. The operation depends on the Faraday effect which is produced by a magnet-optic effect which is the main component called the Faraday Rotator.

The optical isolator can be mounted onto the end of the fiber stub within the receptacle design. Several other types can be used as well such as a cylindrical and surface mount types and can all be offered according to customer's request.

With Lens

Lens Assemblies are the optical components consisting of built in Ball Lenses or Aspherical Lenses fixed in metal holders or housings designed for Optical Devices and Modules. The metal parts are mainly assembled by a press fitting process and sealed with a low-melting glass process.

We can also apply an AR (Anti-Reflection) Coating on the lens surface.

Our Lens Assemblies are custom-made products and we have the ability to manufacture and design these custom products to meet your application needs.

Fiber Stubs

Fiber Stubs are the most important components when connecting Receptacle Modules such as TOSAs and ROSAs Assemblies. The Fiber Stubs are press fitted into the Receptacle Modules and a stable connection is guaranteed with the Fiber Stub and Optical Connectors when mated in the receptacle.

Our Fiber Stubs are typically custom made parts depending on the end user's design but our standard fiber stub length is 4.05mm for an OD of φ2.5mm and a length of 2.95mm for an OD of φ1.25mm.

We can provide various Optical Fiber Clad Diameters in addition to the standard SM (Single mode), MM (Multimode), and PM (Polarization Maintaining) Fibers. We can also offer contract manufacturing services of custom configurations and designs with different lengths, ODs and polish angles. We can also accommodate AR (Anti Reflection) Coating on the fiber stub.

With Pigtail

Fiber Pigtails are required for the manufacturing of Coaxial Modules, Butterfly Modules and Optical Functional Modules. One end of the Fiber Pigtail is terminated with an angled polished SUS Metal Ferrule. The SUS Metal Ferrules are assembled by press fitting our zirconia capillaries into precision metal housings and flanges. SC and LC Connectors are then terminated on the other open end of the Fiber Pigtail.

We can provide various Optical Fiber Clad Diameters, total lengths and polishing end face angles in addition to the standard SM (Single mode), MM (Multimode), and PM (Polarization Maintaining) Fibers.

Since we manufacture the core components such as the ferrules and connectors, low assembly prices can be realized and offered.

Metal Tube

SUS and other material can be used for metal tubing attachment to fibers.

TEC Fusion

TEC (Thermal Expanded Core) fiber is a technique for connecting optical fibers using a fusion process and equipment. We offer various fibers with High NA's, clad diameters and core diameters.

[Examples] *Need confirm

SMFーSMF(HNA: 1/3/7)

PMF (Small diameter HNA) -PMF(Small diameter)

SMF-GI SMF

SMF-Coreless fiber

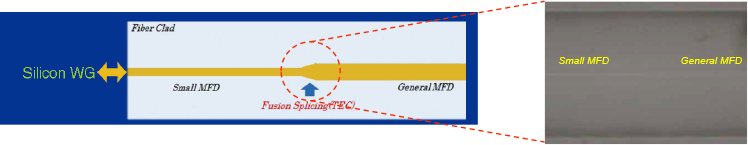

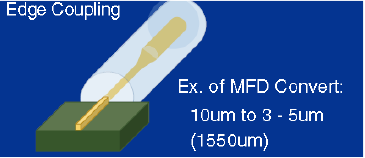

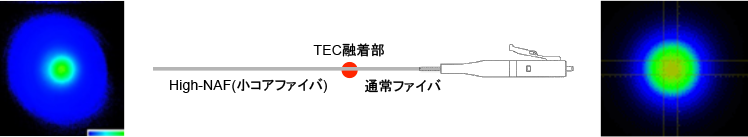

TEC(Thermally-diffused Expanded Core) Fusion Splicing Technology

Locally expanding Fiber MFD by thermal diffusion process, enabling to connect different core diameter with low insertion loss.

Applications

Optical Circuit (PLC, Si-Photonics)

Optical I/O Device with Different MFD

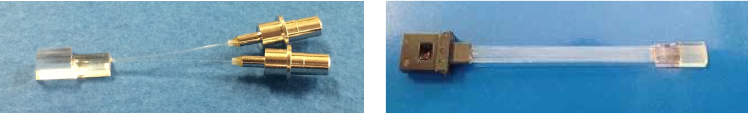

Product example

Fiber Array Assembly by TEC Fusion Splicing.

V-Groove Substrates

The V-Groove Substrate is manufactured by a high ultra precision processing technology. These processes position the optical fiber cores with great accuracy and high precision.

By applying our ultra fine processing technology, our V-Groove Substrates are highly precise, with a flat and smooth processed surface.