Diamond ranks the highest of all materials in terms of hardness, acoustic velocity, thermal conductivity, and Young's modulus. Other notable qualities are its transmittance of a broad wavelength spectrum from ultraviolet to infrared, thermal and chemical stability, controllable electrical resistance/conductivity, and radiation resistance. These properties make diamond an excellent material for a variety of applications, such as heat sinks, machine tools, optical components, audio components, and semiconductor substrates, and for use in outer space.

Diamond Production Method

The present diamond synthesis method is high-pressure, high-temperature (HPHT) method. The homoepitaxial diamond growth process on HPHT-diamond substrate by Chemical Vapor Deposition (CVD) is also well known method for producing diamond substrate. This method is superior in the quality but limits the substrate size.

World's first, large diameter diamond production method

Orbray employs Heteroepitaxy targeting large diamond substrates.

In principal, hetroepitaxy, which uses a foreign material as a basal substrate, has theoretical possibility

of producing diamond substrates with the same size as basal foreign substrates.

However, due to the heteroepitaxial strain owing to the lattice and thermal expansion differences of diamond

and basal substrate, quality degradation and crack generation still occur in thick bulk diamond growth.

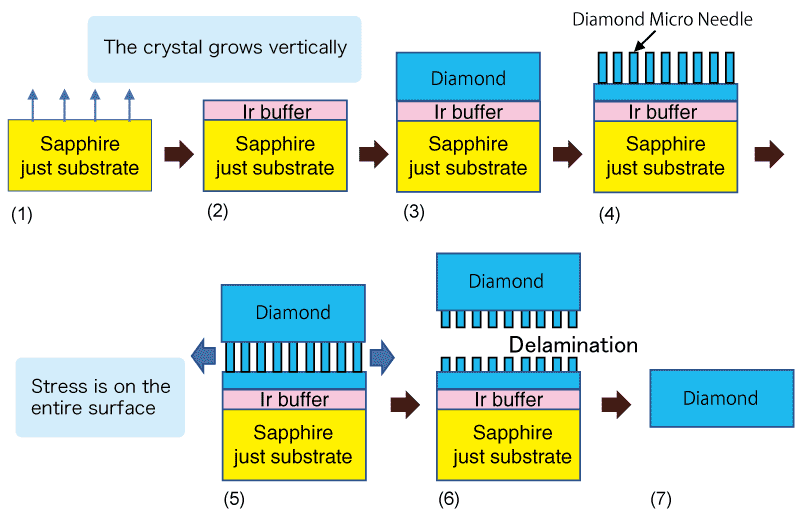

We made a new approach to overcome the above mentioned issues in heteroepitaxy. Based on the world's first

Ir/Sapphire basal substrate process technology, we

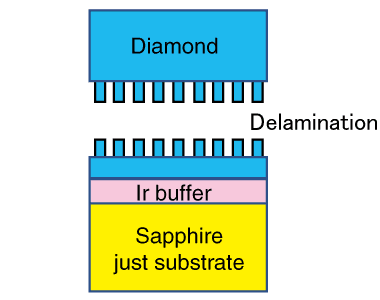

combined with our own newly developed microneedle growth technology (JP Patent 6142415B) which enables to

prevent crack generation and allow to grow stress-free, high quality, large diameter diamond substrate for

stable production. The diamond wafer has been named KENZAN Diamond™.

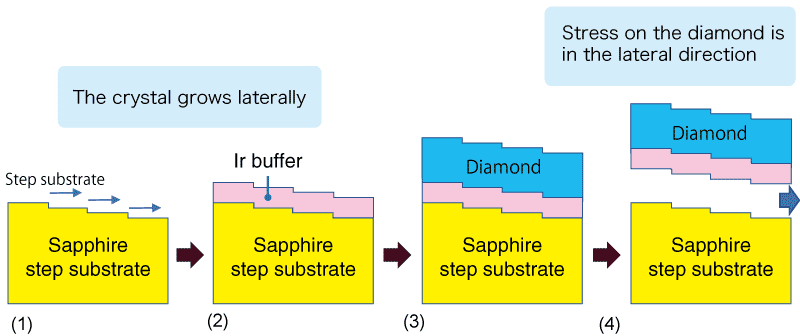

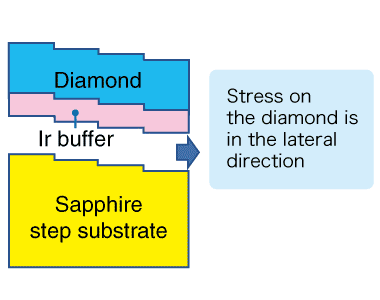

In addition, a novel step flow growth technology was developed to grow two-inch (50 mm) diameter diamond

crystals which are needed for industrial applications. We capitalized on our sapphire substrate technology to precisely

control the base sapphire wafer. The inclined Ir/sapphire surface results in lateral growth of the diamond

crystal, which alleviates stress accumulation during the growth process. We are now tackling the challenge

of further increasing the wafer size, with four-inch diameter as the next stage.

Fabrication technique of KENZAN Diamond™

Novel technology (Step-flow growth)

Simple manufacturing process leads to cost reduction.

Conventional technology (Microneedle growth)

Conventional structure

- A large amount of stress is applied to the grown diamond, causing cracks.

- Microneedles are needed to prevent the diamond from breaking.

- Microneedle fabrication process was complex and costly.

Novel structure

- Step flow growth uses sapphire step substrate.

- Stress on the diamond layer is applied laterally, eliminating the need for microneedles.

- Significant reductions in production time and cost make step-flow growth an appropriate technique for mass production. Two-inch diamond substrate is available.

Related Information (Blog)

- What are Diamonds?

- What are Diamonds?: Synthesis of Diamonds

- Novel Diamond Semiconductors Operate at Highest Power Ever

- Method for mass production of 2-inch diamond wafers developed – Expected to spur industrialization of power-semiconductor devices

- Two-inch

high-quality (001) diamond heteroepitaxial growth on sapphire (11

0) misoriented substrate by step-flow

mode(Applied Physics

Express)

0) misoriented substrate by step-flow

mode(Applied Physics

Express) - Success in mass production technology for ultra-high-purity 2-inch diamond wafer; expected to spur realization of quantum computing

- Element Six and Orbray partner to deliver the world’s highest quality wafer-scale single crystal synthetic diamond

- Mass production of high-quality, self-standing, large-diameter single-crystal (111) diamond substrates within reach. Development of n-Type Diamonds for Practical Use in Diamond Semiconductors also Making Advances

- Evolutionary: World’s Largest Class Single Crystal Diamond Radiation Detector Opening new possibilities for medical and scientific field