The importance of inner peripheral surface evaluation has been increasing for precision

pore-machined parts such as fuel injection nozzles in aerospace instruments, hollow parts in medical

devices, precision nozzles in analyzers, and hydrodynamic bearings.

Existing measuring instruments can evaluate inner diameter, roundness, surface roughness, and shape of

machined parts with relatively large inner diameters. However, these instruments are not able to gauge the

pore-machined parts unless the bodies of the parts are cut in half.

Orbray has developed the “NMH-02”an OCT inner peripheral surface measuring instrument that enables the

visualization of the inner peripheral surfaces of pores using optical interference of near infrared

light.

This unique invention was possible thanks to our micro motor technology and optical communication

technology. It combines our world's smallest φ0.9mm motor with our patented optical imaging probe, and

is equipped with our patented tilt correcting algorithm. It has the following new capabilities: (1)

Measurement of inner diameter as small as φ1.1mm; (2) simultaneous measurement of inner diameter,

roundness, and shape; (3) repeatability to an accuracy of σ=0.2μm; (4) ready-to-use convenience.

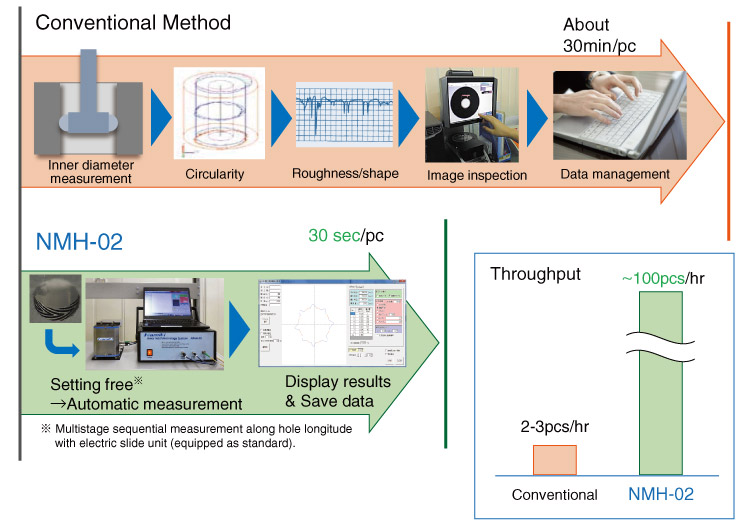

Our instrument is not only able to observe and measure the inner peripheral surfaces of pore-machined parts,

but can also simultaneously evaluate inner diameter, roundness, surface roughness, and shape, which used to

require using separate instruments for each. These features significantly reduce the measurement time from

about 30min to 30sec, and contribute to the improvement of measurement throughput for customers.

Features

- Smallest inner diameter measurable: 1.1mm

- Repeatability with accuracy of σ=0.2μm

- Setting free:work's inclination automatically adjusted by original computing.

- Measuring time:30min (conventional) reduced to 30sec

(simultaneous measurement of inner diameter/circularity/shape)

Comparison to conventional method

- Measurable Minimum Diameter φ1.1mm over

world's smallest φ0.9mm motor installed. - Repeated Measurement Accuracy: 0.2μm

Minimizing optical vibration and fluctuation by translucent standard pipe. - Setting free measurement

Auto- adjusting a work's inclined and eccentric state by arithmetic processing.

Measurement example

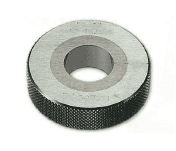

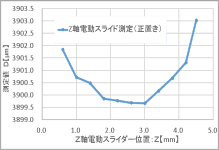

Link gauge

Gauge diameter:

Gauge diameter:

φ3.900

3D picture

Measured result:

Measured result:

φ3.89977

(Center value)

2D inner diameter data Inner diameter data

Inner diameter data

at Z axis direction

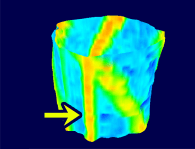

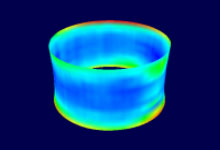

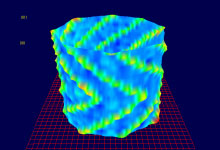

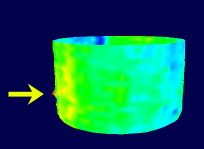

Hydrodynamic bearing

Inner diameter:

Inner diameter:

φ1.60

3D picture

Measured

result:

Measured

result:

φ1.60122

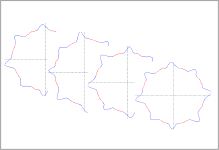

2D picture Auto-detection of

Auto-detection of

dynamic pressure groove

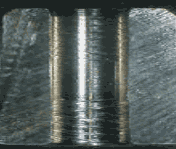

Auto scratch detection

Inner diameter:

Inner diameter:

φ3.900

Dent detection

Vertical scratch detection