Bonding industrial jewel and ceramics without adhesives or heat

Outline: What is room temperature bonding?

This new technology can attach one thing to another instantly by touching the surfaces together. The surfaces are first polished and then thin metal films are deposited on them before bonding. Any material such as metal, semiconductor, glass, ceramics etc. can be joined together. As the materials are not heated and bonding can be done at room temperature, the process is called "room temperature bonding".

The following video shows the bonding of two silica glass wafers (2" diameter, 1mm thickness). You can see a color change from the center to the outer of the wafer by pushing its center by a tweezer. This phenomenon indicates that the deposited metal films are joined together and the wafer bonding finishes instantly.

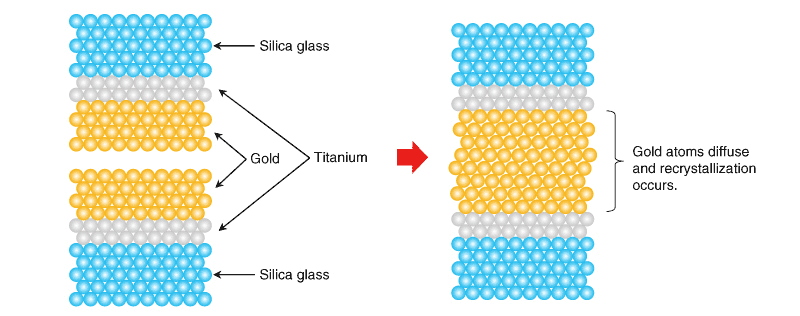

Principle of the room temperature bonding

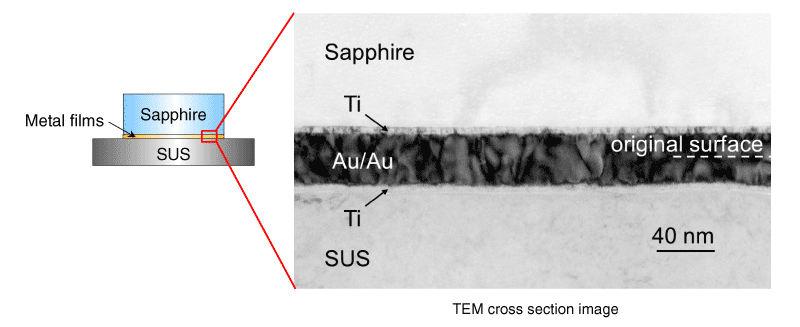

The image below shows the principle of room temperature bonding. Metal films are fabricated on the wafers in a vacuum by sputter deposition. First, titanium under layer films are produced on the wafers to increase adhesion strength and then gold films are formed on top. The wafers are then removed to the atmosphere and the gold surfaces brought into contact. The gold atoms diffuse instantly and recrystallization occurs, completing the bonding.

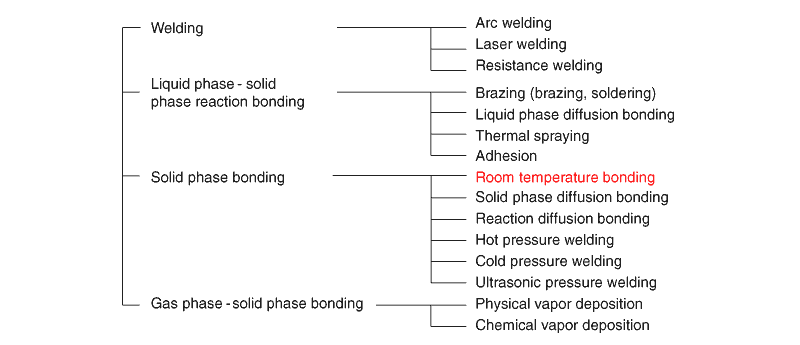

Position of room temperature bonding among general bonding technologies

As shown in the figure below, bonding technologies are classified into four groups: welding by melting the materials, liquid phase-solid phase reaction bonding, solid phase bonding, and gas phase-solid phase bonding. Room temperature bonding is a type of solid phase bonding.

Advantages of room temperature bonding

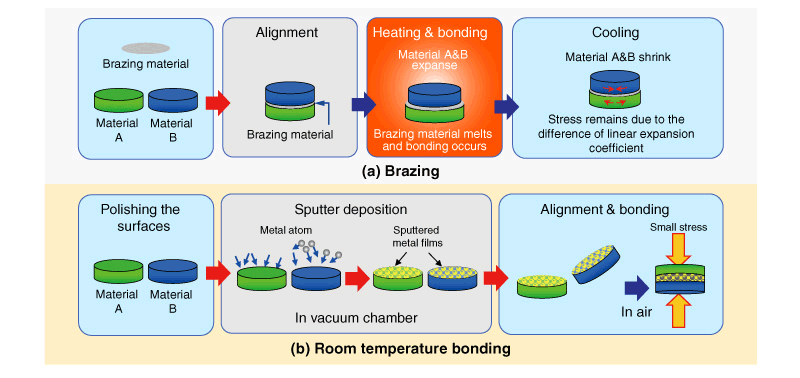

It is not necessary to apply heat by using the room temperature bonding. Let us compare the room temperature bonding to the conventional brazing which needs heat. A figure (a) shows the brazing process. A brazing material is inserted between a material A and B. The materials are heated until the brazing material is melted. After heating, they are bonded together. However, when they are cooled down to the room temperature, the stress remains inside the materials. This phenomenon is due to the difference of the linear expansion coefficient between the material A and B. Namely, the rate of the expansion and shrinkage when heated and cooled are different between A and B. It causes a bow and cracks of the materials. A figure (b) indicates the room temperature bonding process. Surfaces of the materials are polished and metal thin films with thickness of nano meter order are sputtered on them in a vacuum chamber. Finally, the materials are aligned and pressed. They are bonded together without heat, therefore the stress inside the materials are extremely small. The quality and reliability of bonding are advanced. Generally, the room temperature bonding are used for wafer bonding of semiconductor device and optical device bonding etc.

Features of Orbray's room temperature bonding

We have been processing and polishing industrial jewels and ceramics such as ruby, sapphire, diamond, alumina, zirconia, garnet, etc. for eighty years. Our strong point is bonding the materials like industrial jewels and ceramics by the room temperature bonding. Conventional product assembly techniques involve, for example, adhesives for plastics, or brazing for metals. These bonding techniques are of course sufficient in some cases, but may be insufficient for certain applications. For instance,

- When use in a high temperature environment would cause adhesives to melt.

- When use in high pressure or chemical-exposed environments would damage the adhesives.

- When dimensional accuracy is critical and the required precision cannot be achieved with adhesives or brazing.

- When a part is embedded in the human body; brazing material is not biocompatible and cannot be used in this case.

Industrial jewels and ceramics have unique properties such as biocompatibility and excellent resistance to heat, pressure, and chemicals. But how are these materials assembled together?

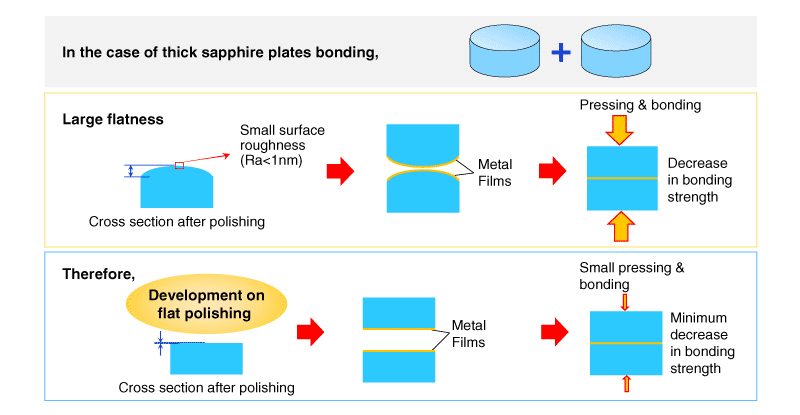

We collaborated with Professor Shimatsu from Tohoku University and have introduced cutting edge room temperature bonding technology. This technology can bond any materials by polishing the material surfaces, depositing the metal nano films, and touching the metal film surfaces. Orbray specializes in polishing techniques for sapphire wafers. Since thin wafers can warp to some extent, they can be bonded with barely any pressure by just pressing them with a pair of tweezers. On the other hand, thick sapphire for high pressure applications does not bend easily, so flat polishing is required in addition to surface polishing. With our newly developed flat polishing technique, we have successfully bonded thick sapphire plates with minimal pressure as well.

There are many advantages of room temperature bonding. For example,

- Any materials can be bonded if the surface roughness is low and degree of flatness is high.

- Materials with different linear expansion coefficients can be bonded together.

- The number of parts needed is reduced since adhesives, O-rings, bolts, etc. are not used.

- Design flexibility is much improved and the components can be simple and compact.

- Materials that are unable to withstand high temperatures can still be bonded.

- It is possible to create a bond that does not degrade in harsh environments.

- There is no thermal stress on materials since there is no temperature change before or after the bonding.

- Accurate alignment is possible since the bonding is done in atmosphere.

- Corrosion resistance is higher because metals like gold and titanium have higher chemical stability than adhesives and brazing materials.

- Bonded interfaces are fully unified without any gaps, so the parts are airtight.

- It can be used in areas where elution of adhesives is problematic, such as for vacuum chambers or physics/chemistry equipment.

- Organic solvents can be used for cleaning after bonding.

As well as many other potential benefits not listed above.

Expected applications

Various viewports, flanged sapphire windows, transmissive windows for ultraviolet and infrared lights, sensor covers, observation cells, crystal arrays, exterior components for jewelry and luxury wristwatches, etc.

By using the metal film positively, the novel optical parts will be expected. We anticipate a continuing increase in applications and innovative ideas for this technology beyond what's listed here. Please feel free to contact us for your prototyping needs.

Practical application example

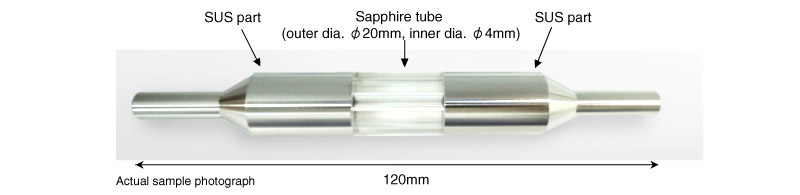

Flow pattern observation with a sapphire tube

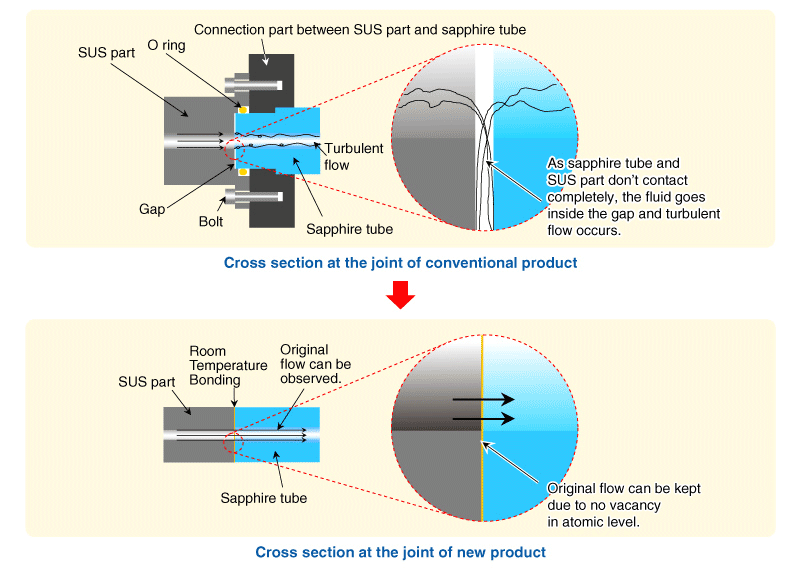

By bonding stainless steel and a sapphire tube at room temperature, we have developed a high-pressure-resistant cell. Using the cell, precise flow patterns of liquid and gas can be observed.

Conventional product

- Complex, multi-part design consists of a stainless steel part, sapphire tube, O-ring, bolts, and a connecting part between the stainless steel and the sapphire.

- Any gap between the sapphire tube and the stainless steel changes the flow, meaning the original flow pattern cannot be observed.

New product

- We collaborated with a pressure-resistant vessel manufacturer, Taiatsu Techno Corporation, to develop a high-pressure-resistant cell for viewing pressurized liquid and gas flow. The stainless steel and sapphire observation tube are bonded directly through room temperature bonding, without the need for O-ring to seal the parts, thereby creating a compact visualization tube that does not affect flow. This part can attach to existing tubes by using bite-type fitting specifications.

- By using sapphire, which has excellent chemical resistance, for the observation area, various kinds of liquids and gases can be observed.

- Maximum working pressure: 20MPa

- Maximum operating temperature: 100℃

- Dimensions: diameter φ20mm x length 120mm

- Sapphire tube dimensions: outer diameter φ20mm x inner diameter φ4mm*

- Observation dimension: length 20mm**

- Materials: sapphire, SUS316

*Inner diameter of sapphire tube depends on the design.

**Maximum observation length is 50mm.

Bonding samples

Sapphire+metals

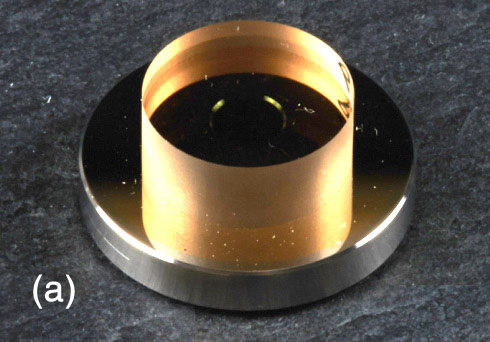

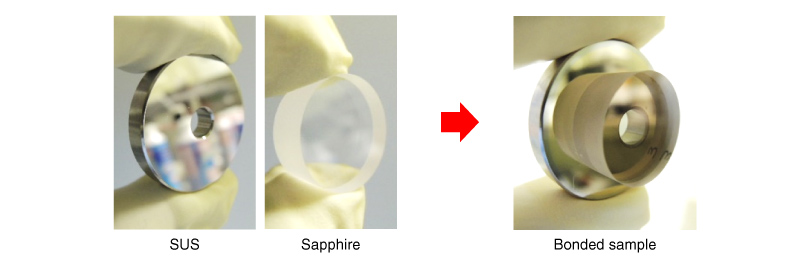

(a) sapphire diameter φ15mm, thickness 6mm; stainless outer diameter φ24mm, inner diameter φ5mm, thickness 4mm

(b) sapphire diameter φ15mm, thickness 6mm; tantalum diameter φ20mm, thickness 3mm

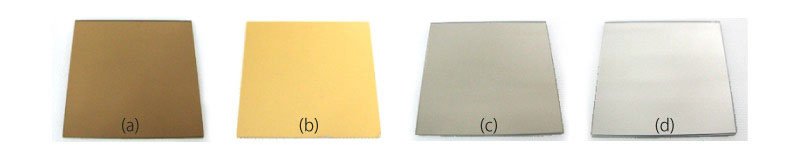

Sapphire+aluminum

By adjusting the composition of the metal film, the sample's color can be changed. Sapphire 30mm□, thickness 0.4mm; aluminum 30mm□, thickness 0.5mm. In (b) only, the sapphire is 0.04mm thick, having been polished extremely thin after being bonded with the aluminum. Although it's difficult to achieve this thinness on sapphire alone due to the likelihood of breakage, bonding it to metal provides reinforcement that makes it possible.

Sapphire+Zirconia

Bonding with ceramics is possible. Sapphire diameter φ33mm, thickness 0.5mm; zirconia diameter φ20mm, thickness 0.7mm.

Photograph from Sapphire

Photograph from Zirconia

Sapphire lens+super invar

Materials with large differences in linear expansion coefficients can be bonded (sapphire 5.3x10-6 /K, super invar0.6x10-6 /K). Sapphire lens processing is done after the bonding. Sapphire lens diameter φ34mm, R22mm; super invar outer diameter φ34mm, inner diameter φ24mm, thickness 22mm.

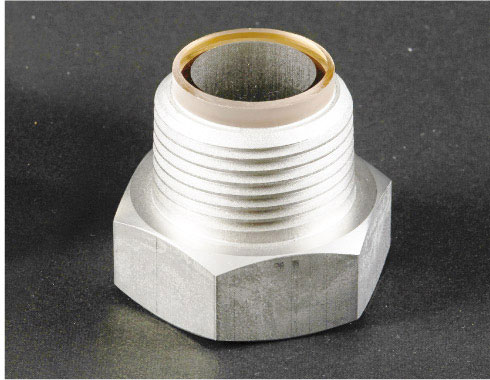

Sapphire window+stainless tube

This is a sapphire viewport for observation inside a reaction vessel. Sapphire diameter φ26mm, thickness 5mm; stainless steel NPT1".

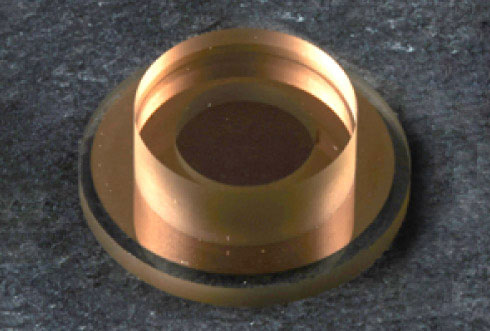

Sapphire+sapphire

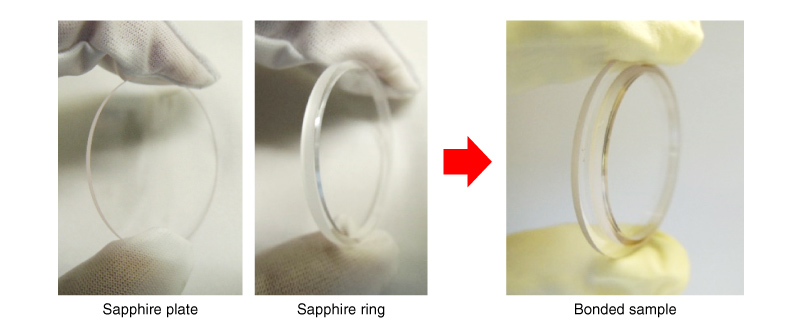

Thick sapphires are bonded. Sapphire diameter φ16mm, thickness 5mm; sapphire ring outer diameter φ24mm, inner diameter φ10mm, thickness 2mm.

Special shaped sapphires can also be bonded. Plate diameter φ36mm, thickness 1.2mm; ring outer diameter φ32mm, inner diameter φ29.5mm, thickness 2mm.

Micro structure

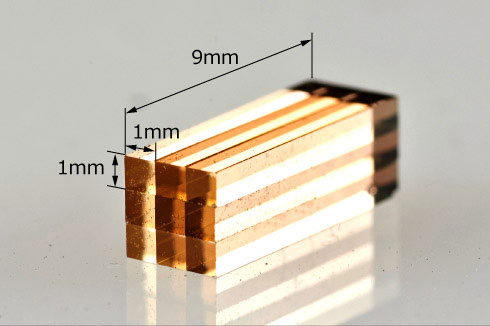

Nine pieces of 1mmx1mmx9mm silica glass bars are bonded.

Bonding properties

Cross section image of bonding interface

The gold has integrated completely, and no interface corresponding to the original Au surfaces is visible. Ti film is deposited as an underlayer. The achieved bonding is excellent, with no gaps or voids at the interfaces of the sapphire, Ti, Au, or SUS.

Reference: M. Ishii, H. Kon, M. Uomoto, T. Nakaya, and T. Shimatsu, "Room Temperature Bonding of Sapphire with Sapphire or Metal Substrates in Air using Au Films", The 4th IEEE International Workshop on Low Temperature Bonding for 3D Integration (2014)

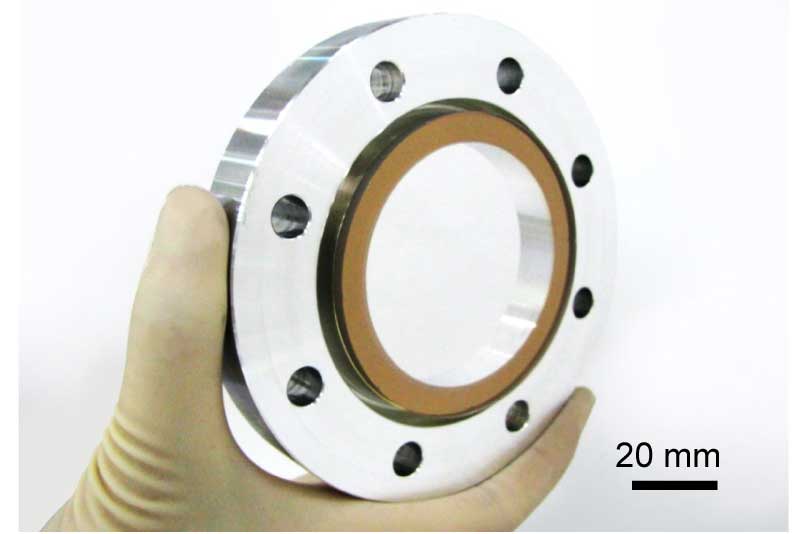

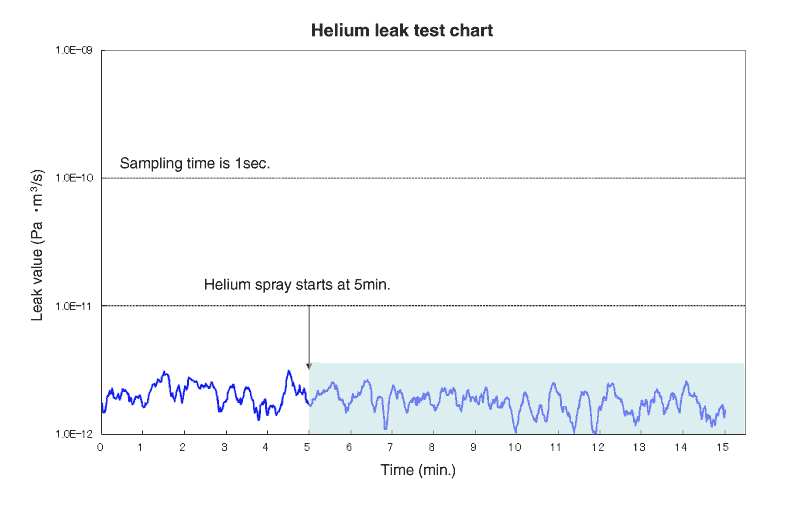

Hermetic evaluation: Helium leak test

We produce a viewport for vacuum equipment that consists of an aluminum flange and a sapphire window bonded by room temperature bonding. Hermetic evaluation of the bond is carried out by the helium leak test. After spraying helium, if the leak measurement value does not increase and keeps the standard value of less than 1.3×10-11 Pa・m3/sec. It means the viewport has a good hermetic seal.

Reference: M. Ishii, H. Kon, M. Uomoto, T. Nakaya, and T. Shimatsu, "The development of sapphire viewport for ultra high vacuum by using the room temperature bonding in air with Au thin film", Proceeding of 29th Spring Meeting of Japan Institute of Electronics Packaging, pp.197-198 (2015)