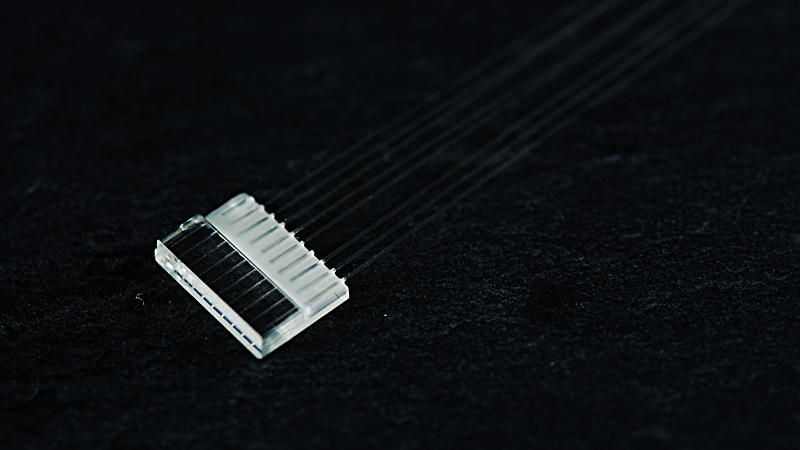

Optical fiber array units are essential devices for high-precision connection of optical waveguide elements and optical fibers in coherent optical fiber systems, co-packaged optics and other fiber systems and platforms. Coherent optical communication systems use phase information of light to achieve high-speed and large-capacity data transmission. Therefore, it is important to minimize connection loss and return loss to maintain light signal transmission efficiency and signal quality. To fulfill this role, fiber arrays require extremely high precision and stability in the connection of optical waveguide elements (silicon photonics, PLC: optical waveguide circuits, self-forming waveguide, etc.) and optical fibers.

V-groove substrates and ultra-precision processing technology

Optical fiber arrays are manufactured by precisely arranging and fixing optical fibers in a horizontal row on V-groove substrates, which are mainly made of glass or silicon and formed by etching or grinding using semiconductor processing technology. The V-groove formation accuracy is controlled at the nanometer (nm) level, requiring positioning accuracy on the order of sub-microns (0.1 µm) relative to the outer diameter of the optical fiber (typically 125µm).

This high-precision positioning ensures that the optical fiber core is precisely aligned to maximize the coupling efficiency of the optical signal to the optical waveguide element. In addition, fiber end faces are polished with physical contact (PC) and angle polish (APC) to reduce return loss and insertion loss. In particular, APC minimizes signal degradation due to reflection by allowing light reflections to escape at an angle of about 8 degrees.

Technologies for Reducing Connection Loss

Connection loss in optical fiber arrays can be divided into insertion loss and return loss.

Insertion loss is caused by fiber core misalignment and end-face quality variations.

Return loss is caused by interference and returned light from reflected light at the end face of the optical fiber.

In our optical fiber arrays, the following technologies are adopted to minimize these losses.

- Sub-micron core position adjustment – Improved V-groove processing precision which allows for precise positioning of optical fiber cores.

- End-face polishing technology - PC/UPC/APC and other polishing methods are applied to reduce connection loss.

- Low-loss UV adhesives - Adhesives with excellent optical properties are used to suppress light scattering at the connection area.

Integrated LD/PD Waveguide and Fiber Array Devices

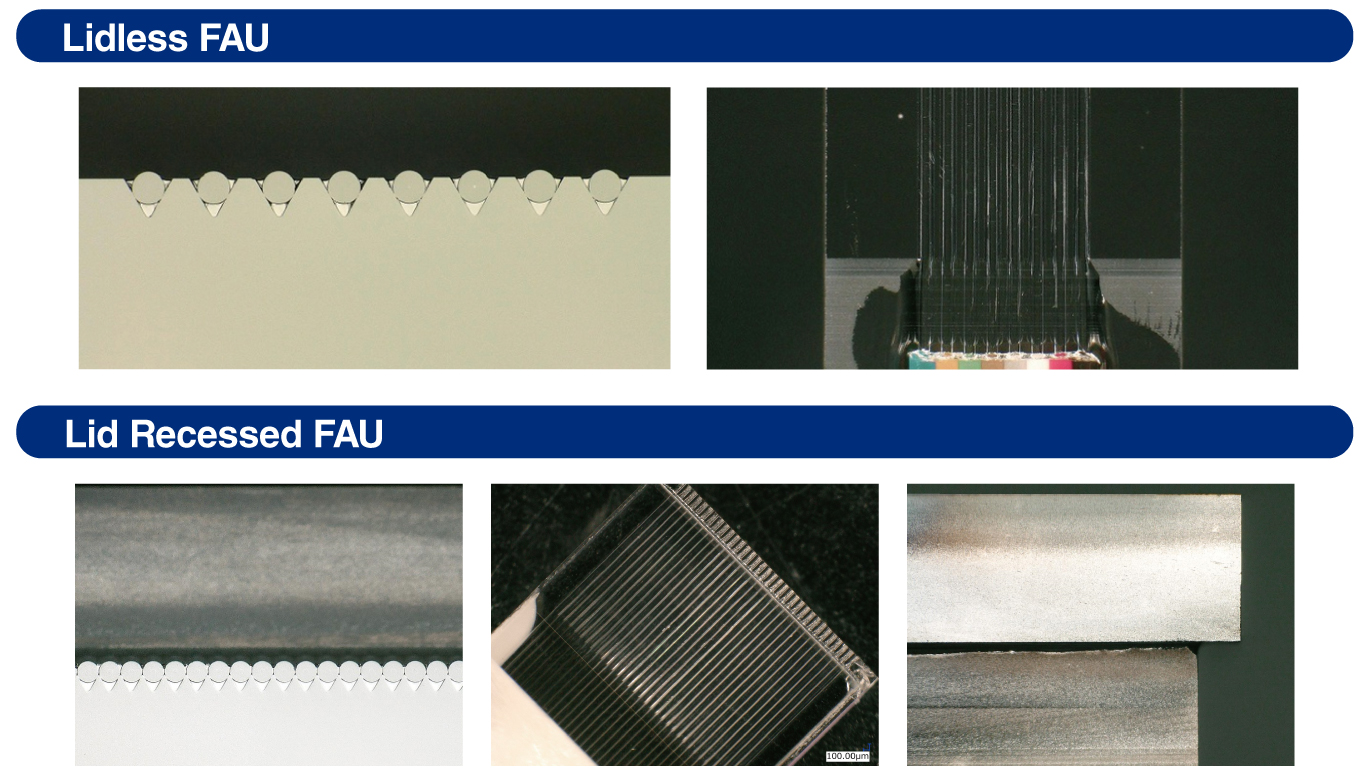

Optical communication systems require highly efficient connection between light emitting/receiving elements such as LD (laser diode) and PD (photodiode) and optical fiber. In particular, LD/PD array devices are becoming increasingly dense, and integrated devices using fiber arrays play an important role.

We manufacture fiber arrays that support direct fiber coupling to these LD/PD waveguides.

- High-density, narrow-pitch structures - fiber-to-fiber pitch is less than 125 µm, enabling high-density connection.

- Optical lead frame - Integrated structure of waveguide elements and optical fibers ensures positioning accuracy and stability.

- Low-loss coupling - Connector loss is kept below 0.1dB to maximize optical signal transmission efficiency.

Our Unique Optical Lead Frame Technology

Orbray offers “optical lead frame” that integrate fiber arrays and waveguide elements. This lead frame integrates:

- Forming V grooves on a silicon or glass substrate

- Precise placement and fixing of optical fibers

- Direct coupling with LD/PD devices

Furthermore, the optical lead frame minimizes the connection distance between the LD/PD or silicon photonics device and the fiber array, thereby shortening the optical path length and minimizing losses. Narrow pitch arrays (pitch less than 100µm) and multi-channel configurations are also supported, making this design ideal for the latest coherent communication technologies and data center applications.

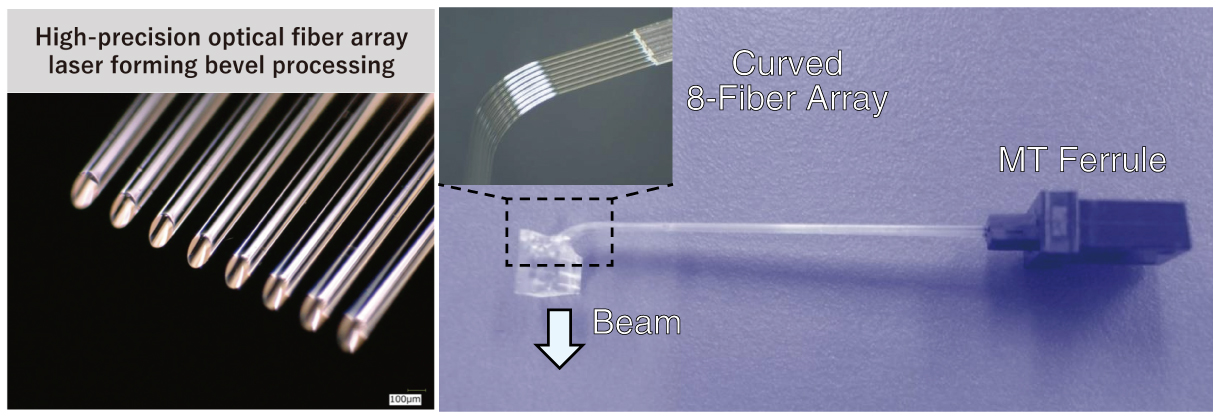

Bending Fiber Array

A bending fiber array is formed by a thermal process technique of the optical fiber to form a permanent bend within the fiber that can then be assembled into an array.

It is mostly used for the bonding and direct coupling to a SiP (Silicon Photonics) chip in small form factor module devices.

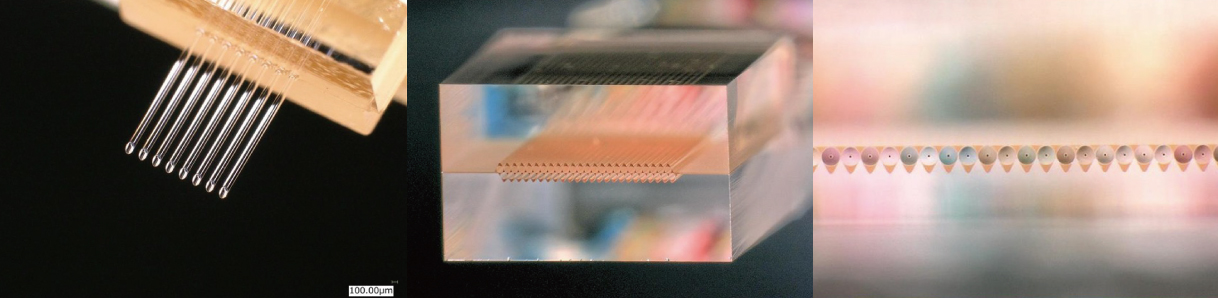

Narrow Pitch Fiber Array

The narrow pitch fiber array is a connection device made by our fiber etching technology and V-Groove Substrate processing technology. It is mostly used for the bonding and direct coupling to a SiP (Silicon Photonics) chip in small form factor module devices.

For a standard SMF fiber with 125μm clad diameter with a typical pitch of 250μm, we can taper and narrow the pitch to 50um by our fiber etching technology and mount within the V-Groove Substrate.

Fiber Array Bending, Angle Polishing, MPO Connector Assembly, Fiber Array with PMF and MCF in-line

Future Outlook

Advances in optical communication technology are accelerating the speed and density of coherent communications. In-line with this trend, the demand for connection accuracy and stability between optical waveguide elements and optical fibers is further increasing. In particular, fiber arrays with narrow pitch, low loss, and high stability are indispensable for next-generation optical communication standards such as 400G to 1.6T.

Orbray is developing products that will support even higher density and precision in the future by strengthening its proprietary ultra-precision processing technology, V-groove technology, and end-face polishing technology. This will contribute to higher performance and lower costs in next-generation optical communication systems.

Example of use

Optical transceiver , Micro ICR , Wavelength-Multiplexing Device , Splitter , OADM , Bandpass filter , Laser related equipment of each wavelength , Other multiple high-density fiber integration devices and such.