What is Metallic Glass?

Metallic Glass (Bulk Metallic Glass / liquid metal) is a new type of amorphous metal with unique features.

Conventional amorphous metal could only be used to make thin and small items because it crystallizes unless

rapidly cooled from the molten alloy state.

Metallic Glass, however, solidifies without crystallization even if cooled down slowly from the molten alloy

state, so relatively large bulk products can be fabricated, expanding the range of applications for

industrial use.

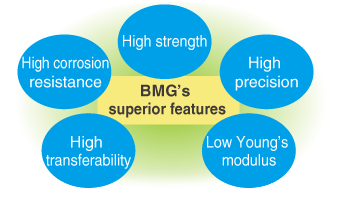

In addition, Metallic Glass has several excellent mechanical properties, such as high strength, low Young's

modulus, high transferability, and excellent corrosion resistance.

Utilizing these characteristics makes application possible in a variety of fields, such as high-precision

components, exterior components, sensors, springs, sports equipment, and biomaterials.

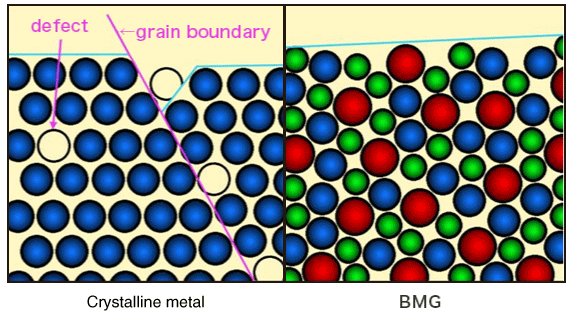

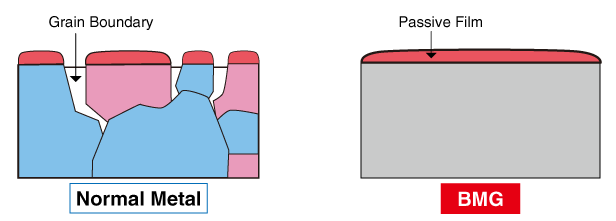

Difference in atomic arrangement between normal metal and metallic glass

Superior features of Metallic Glass: high-precision transfer

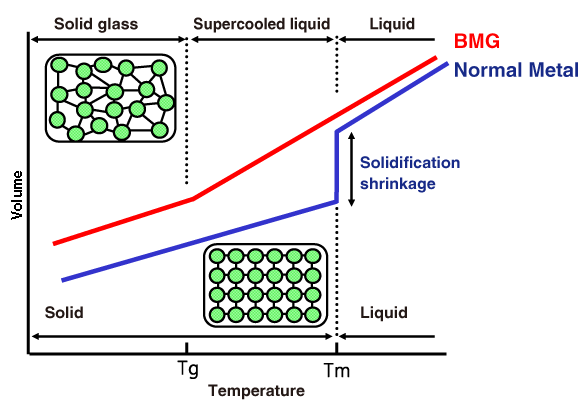

When cooling from liquid state, no solidification shrinkage occurs, and it solidifies into a non-crystalline state.

Good dimensional accuracy & high molding transfer precision

The above chart shows the relationship between the temperature and volume of metallic glass. (Red line:

metallic glass, Blue line: normal metal).

When cooling from liquid state, normal metal undergoes solidification shrinkage associated with

crystallization, which results in a reduced volume.

Metallic glass, however, solidifies in non-crystalline state. Therefore, the surface of the mold can be

fully transferred, and parts can be manufactured with high dimensional accuracy.

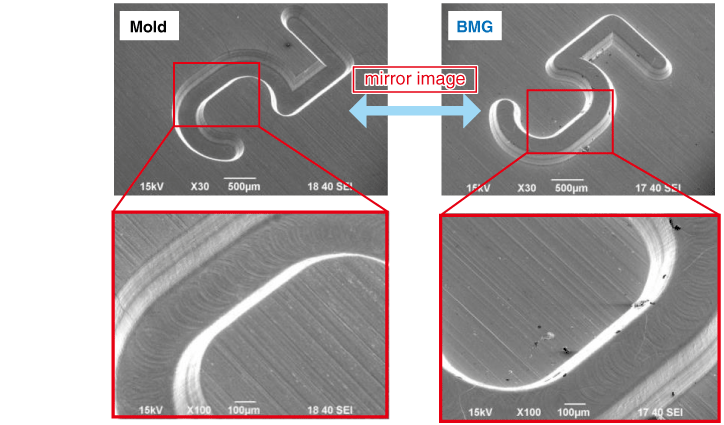

Metallic glass's molding transfer precision

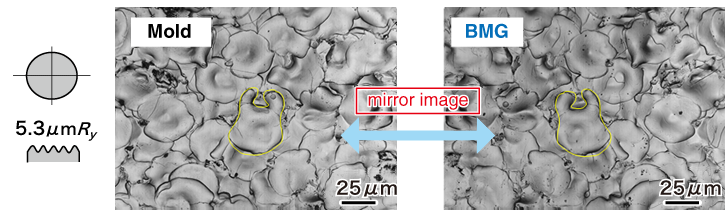

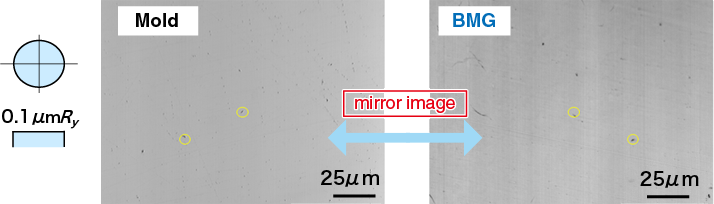

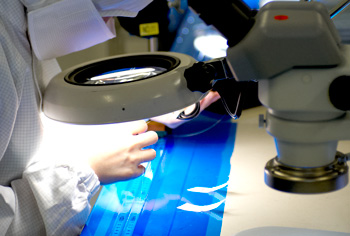

Photos of the mold's surface and the casting surface.

The processed pattern on the mold's surface is fully transferred onto the casting's surface.

Surface transfer of an EDM-produced mold

Surface transfer of a polished mold

Surface transfer of a character mold

Metallic glass's corrosion resistance

Normal metal has grain boundaries as shown in the above figure, which can be starting points for corrosion. Metallic glass, however, doesn't have grain boundaries, and a continuous passive film forms on the surface. Therefore, it doesn't corrode easily, even in harsh environments.

Metallic glass's physical properties

| Item (unit) | Zr-BMG physical properties

Composition(wt%): Zr67.02Cu25.46Ni3.92Al3.60 (at%): Zr55Cu30Al10Ni5 |

|---|---|

| Density [g/cm3] | 6.8 |

| Tensile strength [MPa] | 1620 |

| Vickers hardness [Hv] | 520 |

| Young's modulus [GPa] | 81 |

| Poisson's ratio | 0.34 |

| Resistivity [μΩ・cm 80℃] | 180 - 210 |

| Magnetic susceptibility [μemu / (g・Oe) 20℃] | 1.2 - 1.5 |

| Melting point [℃] | 890 |

| Glass-transition temp. [℃] | 410 |

| Thermal expansion coefficient (E-6/℃) | 10.9 |

| Thermal conductivity [W/(m・K)] | 5.5 |

| Specific heat [kJ/(kg・K)] | 0.33 |

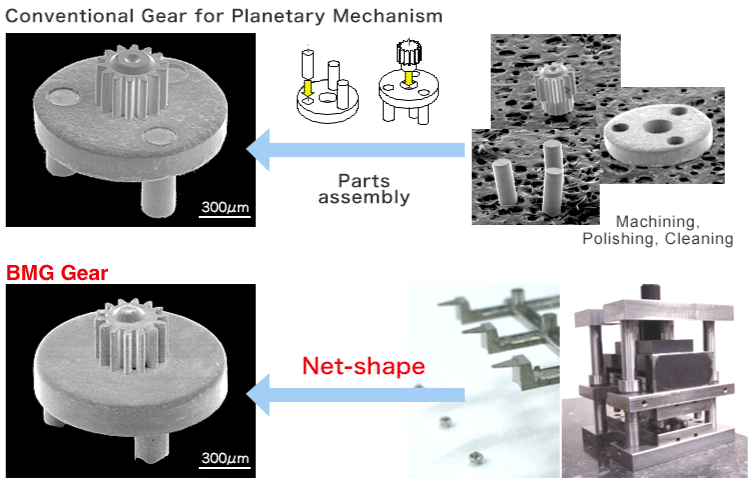

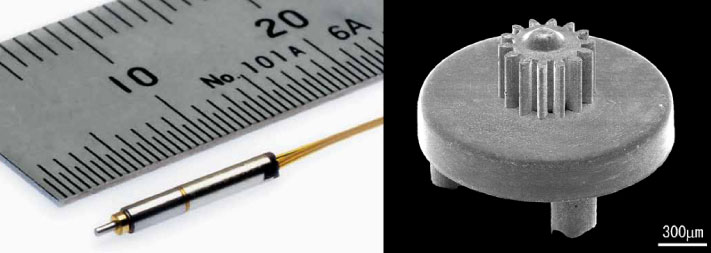

Metallic glass micro gear

Moldable by near net shape

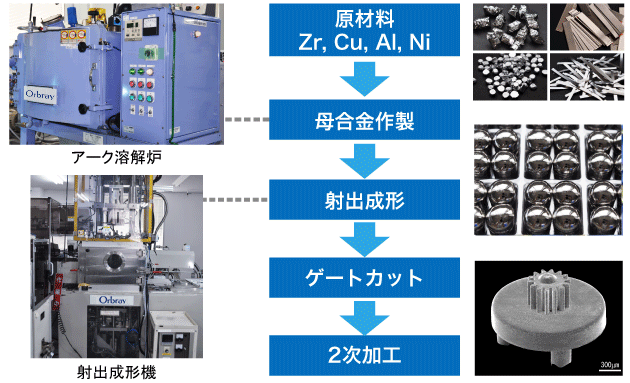

Metallic glass process flow

Metallic glass is produced by injection molding by using a mother alloy with the same composition as metallic glass.

Vacuum chamber

Die

Mother

Alloy

Coil

Sleeve

Piston

Melting

Metaltic Glass

Injection

Vacuum chamber

Die

Mother

Alloy

Coil

Sleeve

Piston

Melting

Metaltic

Glass

Injection

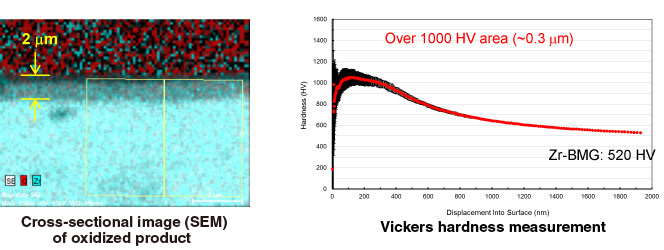

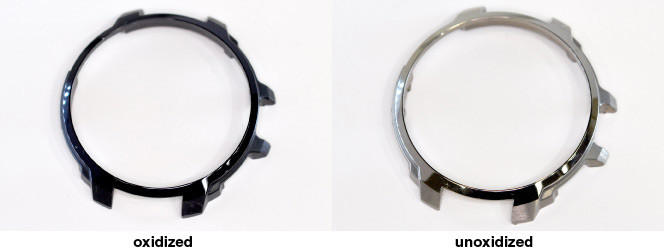

Surface treatment of metallic glass

When oxidized, metallic glass turns a dark blue color and a hard film forms on the surface, making it even

more scratch-resistant.

The color of the metallic glass can also be changed by applying IP coating, DLC coating, etc.

In addition, IP coating, DLC coating, etc., can be applied to change the color of the metallic glass.

Metallic glass's superior features

Metallic glass is expected to be applicable in a variety of fields due to its superior features such as high strength, precision mold transferability, corrosion resistance, and flexibility.

Micro gear

Metallic glass is expected to be applicable in a variety of fields due to its superior features such as high strength, precision mold transferability, corrosion resistance, and flexibility.

Expected Applications

Watch exterior, glasses and accessories

Metallic glass can be used to create products that are high-strength and

scratch-resistant. It does not corrode even in harsh environments and does not cause metal allergies or

associated skin reactions.

Our company's metallic glass had been used and commercialized for the exterior parts of luxury watches.

Glasses parts and accessories

With characteristics including flexibility and high strength, metallic glass is expected to be useful

in making eyeglass parts. Unique designs can be achieved by forming fine patterns and logos on the

surface.

These features also make metallic glass a promising material for rings and other accessories.

Automobile pressure sensor

In recent years, with the advancement of process control in the automotive and other industries, there is a need for advanced sensors. Metallic glass has the advantage of being about three times more flexible than normal metals. By using Metallic glass for the diaphragm of a pressure sensor, the diaphragm is possible to be more flexible, resulting in a high strength, high sensitivity sensor.

Orthodontic tool, biomaterial, artificial joint

Small, high-precision orthodontic brackets can be manufactured using metallic glass. We

have developed a small, circular orthodontic bracket of our own design. High precision slot formation

minimizes movement of the corrective wire and facilitates treatment.

Additionally, the reduction in size can ease the burden on the patient during correction as well as

discomfort in the mouth.

BMG is also under consideration for use in biomaterial applications such as artificial bones and dental

implants. Currently titanium, which has excellent biocompatibility, is the main material used for these,

but there are problems such as poor processability and limited shape. BMG has high strength, flexibility,

and a high degree of freedom in shape, and is expected to be a next-generation material to replace

titanium.

Acoustic parts

Metallic glass is characterized by a low vibration damping rate. For example, wind chimes made of

metallic glass have a long-lasting beautiful tone.

Taking advantage of this feature, it is expected

to be applied to musical instruments and audio equipment.

For research and development

We are always available to provide technical information about metallic glass and discuss its potential applications. However, due to limitations on our manufacturing facilities and inventory, we will consider whether we can provide samples upon consultation.