Containers made of single crystal sapphire are resistant to corrosion from hydrochloric

acid, sulfuric acid, nitric acid, etc.

Our company can produce container/crucible shaped sapphire by growing tubes from a seed crystal base with

our unique EFG growing methodology.

As sapphire is a transparent material, it can be confirmed visually if a container has acids inside, such as

those mentioned above, helping to avoid dangerous misuse.

Sapphire has many superior properties including heat resistance, scratch resistance, corrosion resistance

and plasma resistance. It is optimal for observation of molten and/or high temperature material as it

maintains transparency even under high temperatures that quartz glass cannot withstand.

In this way sapphire containers ensure the same transparency and wettability as glass even in environments

in which glass cannot endure.

Although Teflon may be selected as a common material for various analyses, repeated use can cause

contamination to stick to the surface and discoloration to occur.

Since sapphire eliminates surface contamination and controls dust generation, its applications extend to

components analysis that require visibility and corrosion resistance, such as observation in liquid.

Please feel free to contact us regarding shape, dimensions, or product development consultation for

physicochemical applications.

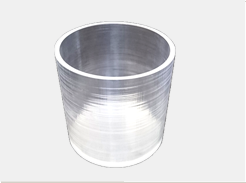

Crucible

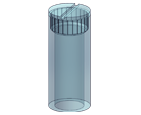

Tube

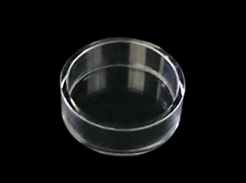

Schale

| Products | Size | External dimensions | Internal dimensions |

|---|---|---|---|

| Crucible | 30cc Equivalent | φ60x18H | φ50x16H |

| 50cc Equivalent | φ60x28H | φ50x26H | |

| 100cc Equivalent -1 | φ60x55H | φ50x53H | |

| 100cc Equivalent -2 | φ70x39H | φ60x37H | |

| Schale | OD17xOH7 | φ17x7H | φ13x5H |

| OD60xOH23 | φ60x23H | φ50x15H | |

| OD90xOH23 | φ90x23H | φ80x15H | |

| Tube | φ25 | φ25x250 | φ21 |

| φ50 | φ50x250 | φ46 | |

| φ75 | φ75x250 | φ71 | |

| φ100 | φ100x250 | φ96 |

In addition to examples, we provide various processing technologies to meet your needs.

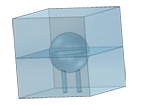

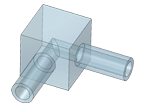

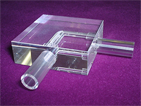

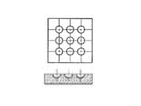

Customized Sapphire Processing Examples

Because sapphire has a hardness (HV2300) which ranks second to diamond, it cannot be cut like common metal. Moreover, sapphire is an insulator material, so electrical discharge machining is not possible either. Therefore, fine hole drilling (um order of magnitude) is carried out using customized Fs (Femtosecond) laser and UV laser processing. In addition, it is also possible to apply polishing process to holes with diameters over 35um.

| Cross Section | Stereophonic Views | Processing Examples | |

|---|---|---|---|

| Customized Sapphire Processing Examples(1) |  |

|

|

| Customized Sapphire Processing Examples(2) |  |

|

|

| Customized Sapphire Processing Examples(3) |  |

|

|

| Customized Sapphire Processing Examples(4) |  |

|

|