Unidirectional oriented Porous Ceramics

(High strength micro-porous ceramics)

What are porous ceramics?

As the name suggests, porous ceramics are ceramics

that have a large number of minute holes (pores) in their structure. Because they have empty holes, porous

ceramics are lightweight, (lighter than resin sponges) and have low heat capacities. The pores can also be

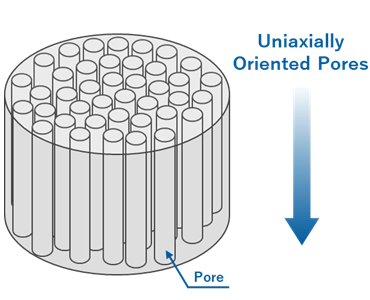

made unidirectionally. Long, unidirectional pores allow air to pass through the ceramic material while maintaining high rigidity and

stiffness.

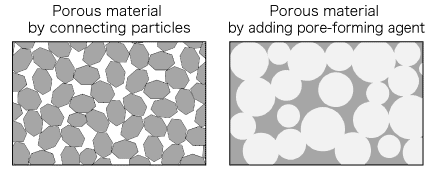

Generally, ceramics refer to a class of inorganic materials which are created by hardening powders at high

temperatures. In the case of porous ceramics, the powder is baked at a temperature that does not allow

complete densification, or by adding materials that create pores in the structure during the baking process.

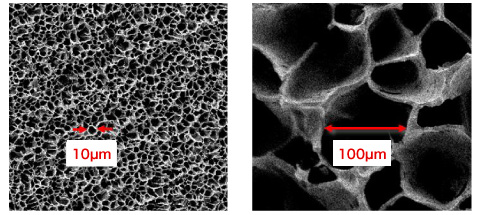

However, the process becomes more difficult as pore sizes get smaller. At smaller sizes, the pores often

close, creating independent closed cells, which reduces the porosity of the ceramic. Using our own

technology, Orbray's porous ceramics maintain high porosity even at very small pore sizes of several dozen

micrometers.

Orbray's porous ceramics take advantage of the high chemical stability and heat resistance of ceramics to

create various filtering solutions for water treatment and exhaust mufflers, as well as jigs and vessels for

high temperature processes. In addition, there has been a recent focus on using this high-performance

material for environmental purposes.

Features of Orbray's porous ceramics

Pore structure

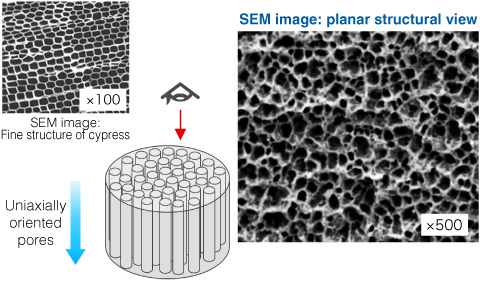

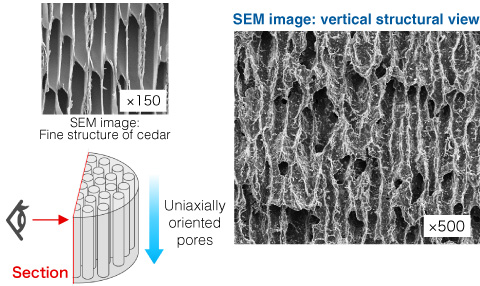

Pore orientation

The pores of Orbray's porous ceramics can be oriented in any desired direction. Contrary to most other porous ceramics available, our pores are connected to each other, creating an open cell structure while maintaining high stiffness and rigidity.

Pore structure components

It is possible to create a densified layer on the outer circumference of our ceramics. The walls of the unidirectional pores can also be hardened. In this way, it is possible to create nano-porous structures in a controlled manner.

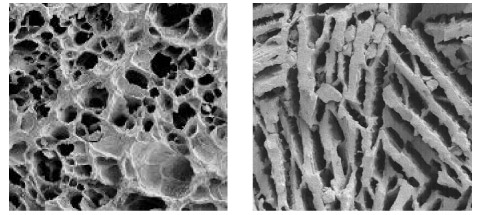

Pore shape

High control of pore shape and structure

In addition to controlling pore size, it is also possible to create ceramics with pores of varying sizes. The shapes and arrangement of the pores can also be changed as desired.

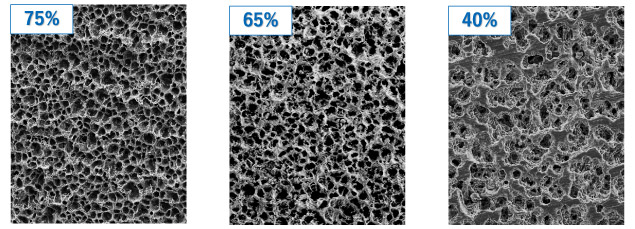

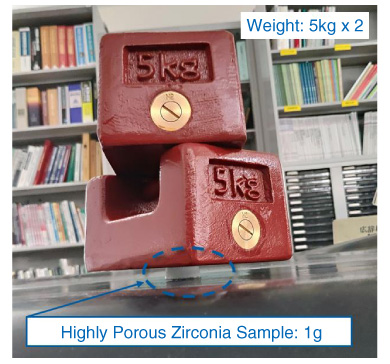

High porosity sample

Extremely high porosity and rigidity

Orbray's porous ceramics are made by “controlling the dispersion of particles” and

“controlling shrinkage of the ceramic in the

baking process” at very high levels. This results in very high porosity of the ceramics. In addition,

the unidirectional arrangement of the pores results in very high rigidity (able to support 10,000 times

its own weight).

We have demonstrated porosity of greater than 97% with a density of 0.17

g/cm3. This is extremely light for any ceramic material, being light than some resin

sponges.

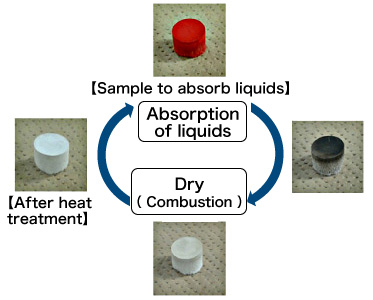

Water absorption and heat characteristics

Absorption and removal of liquids

The ability of the ceramic to absorb liquids can be optimized by modifying the pore diameter. The high porosity will allow the ceramic to absorb a large volume of liquid. The loaded ceramic can be dried and treated at high temperatures without worrying about damaging the structure and can be used repeatedly.

A cool 200 deg C.

Since the porous ceramic is mostly air, its heat capacity is very small. In addition, this ceramic can be made with materials that have low heat conductivity. A material with now heat capacity and low heat conductivity can be heated to 200 deg C and still be picked up bare-handed. With the densified outer layer, the ceramic can be handled easily even though it is highly porous.

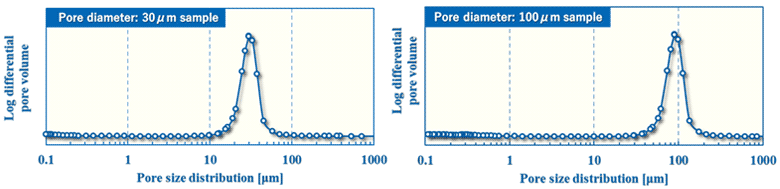

Pore size distribution

Our company's porous material has a sharp pore size distribution with little variation in pore diameter.