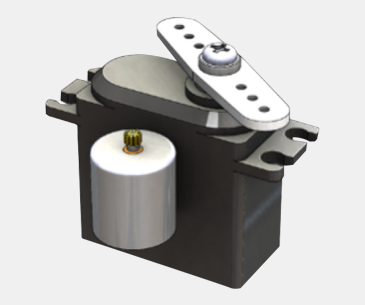

This is an RC servo motor that has been developed in pursuit of "high responsiveness" and "high output" alongside the evolution of battery technology.

Brushed Motor

Rotor is made of a cup-shaped coreless winding coil. It features low inertia, and high speed response.

Brushless Motor

Stator is a coreless coil winding. No cogging in rotation, designed to run large current input, high output and high heat dissipation.

The characteristics required for RC servo motors are distinct from those of other applications. Therefore, Orbray continues to develop motors specifically for RC servos, separate from its standard lineup. RC servos are used in applications such as RC cars and RC airplanes, where they handle tasks like directional changes. These motors constantly operate under conditions of high current flow and high coil temperatures. To ensure optimal performance in these harsh environments, Orbray's RC servo motors are designed with fast mechanical time constants (from stop to maximum speed) and high output (high torque). These features are crucial factors in determining the superiority of an RC servo. Today, Orbray offers sizes such as φ12x15L, φ17x15L, φ17x18L,and φ17x25L, maintaining a leading market share in the industry. These motors are also applied in various communication robots for servos and are used in a wide range of applications.