Motor Selection Guide

It is rare that the customer knows all the information required for selecting a suitable motor. Usually, we select a suitable motor based on limited information for customers to try first. After an adjusting and modification process the customer can reach a satisfactory motor solution.

Like playing golf, the most important point is to get your first shot (1st trial motor) on the green, if not hole-in- one. To do so requires as much and as accurate of information as possible in the first stage.

FROM YOUR INQUIRY TO MASS PRODUCTION

STEP1

BEFORE YOUR INQUIRYThe kind of motors (small coreless/brushless) Orbray provides are only one tiny part among many other kinds of motors used in the world. First, please check the following points to see if Orbray motors may be an ideal fit for your application.

- Motor size Φ4~Φ30mm

- Smooth and stable operation required(no cogging)

- Reasonable project quantity

STEP2

BASIC INFORMATION FOR MOTOR SELCTIONPlease collect the following basic information.

1. Application

What is the application and how is the motor used in it?

Example: lens operation for security camera

2.Size limitation

Please check the total size limitation in your application including gear/encoder, etc.

Example: max Φ16

x 55mm length including gear 16mm x 55mm

3.Voltage/Torque/Speed

Power Supply

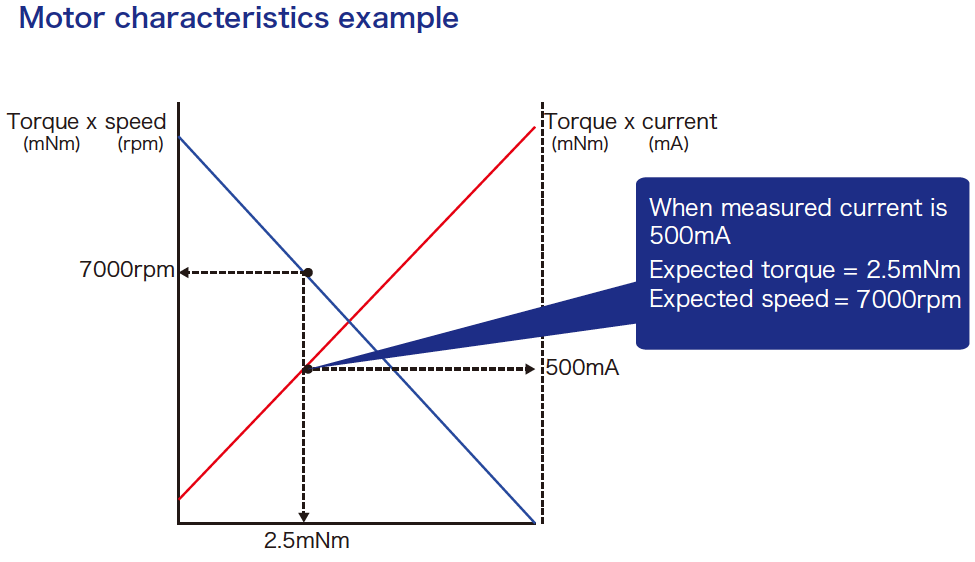

Motor’ s torque and rotation speed depends on the voltage and current

provided by the power source. First, please check if the power source is a stabilized power supply or

battery.

Voltage(V)

Motor’ s torque and rotation speed depends on the voltage and current

provided by the power source. First, please check if the power source is a stabilized power supply or

battery.

4.Motor usage time and frequency

Please check how long at a time you would use the motor (application), and how often. Using the motor at excessive torque for too long a time may impact the motor life time.

Example: max 5 minutes at one time, 10 times/day, more than 1 year expected

STEP3

MOTOR SELECTION PROCESSBased on the acquired basic info in Step 1 - 2, let us select the matching standard motor (CMS/BMS) or geared motor.

Basic info

- Size: φ16 x 55mm

- Power supply: Stable

- Voltage: 12V

- Required torque:50mNm

- Required speed: 300rpm ~ 400rpm

1. Refer to ALL MOTOR SPEC CHART and find the matching motor based on size and rated torque.

Point 1: Based on product name you can figure out the overall dimension.

Example: CMS16-3306 = Φ16, total length 33mm, resistance 6Ω

Point 2: Torque and speed is in proportion to voltage.

| Voltage | 7.4V → 10V |

|---|---|

| Torque | 3.4mNm → 4.6mNm |

| Rotation speed | 25000rpm → 33780rpm |

As a result, you can see there is no Φ16 motor alone that matches the requirement at 12V.

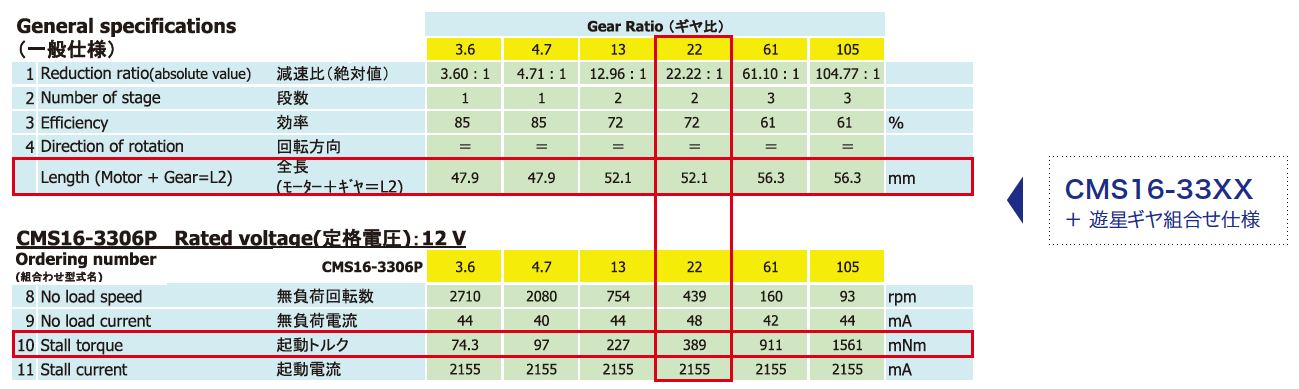

2. Now refer to CMS CORELESS MOTOR WITH GEAR and look for matching geared motor. As a rough idea, motor torque can be up to 1/4 of the stall torque dependi ng on usage conditions.

CMS16-3306P22

CMS16-3306P22

→ At 50mNm, rotation speed ≒ 382rpm

Now, you know CMS16-3306P22 geared motor may roughly meet your requirement. For further support, please contact our sales team.

STEP4

APPLICATION-SPECIFIC INFORMATIONDepending on your application and usage environment, some motor specs may need to be customized for comfortable use in the long-term. Please see if any of the common requirements below apply to your application needs and kindly inform us of any other special requirement.

1.Long life timeApplications: Blood analyzer, Electric nail file, insulin pump, etc

Generally, a coreless motor's life time ranges from 100h - 1000h, and a brushless motor's is over 10000h depending on the usage conditions. If your application requires longer life time, please provide detailed operating conditions and ideal motor life time. By adjusting/changing brush and commutator, coreless motor life time can be improved.

2. High durabilityApplication: Electric lock, Electric nail file, Tattoo machine, Industrial robot, etc

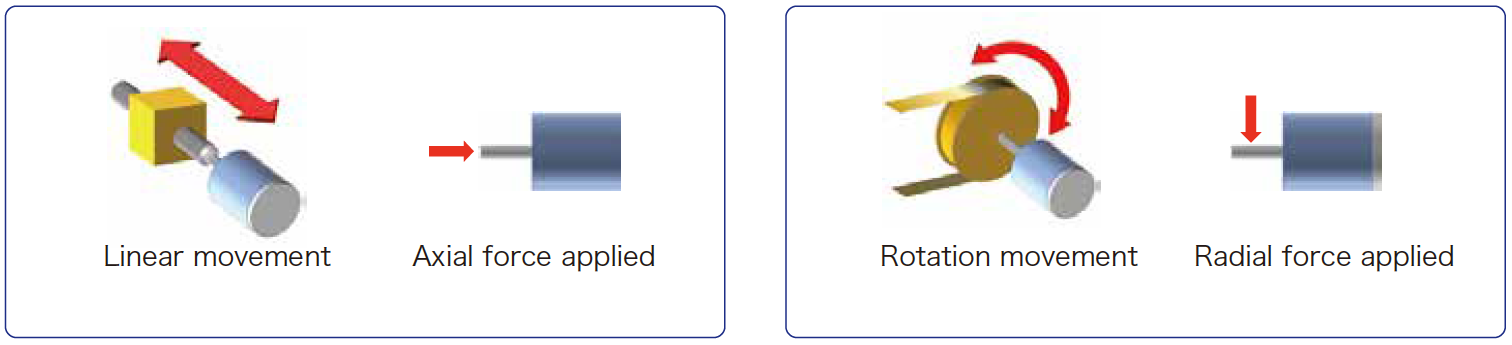

When the motor is built into customer’ s application, please check the force direction (radial/axial) applied on the motor/gear shaft (See below illustration). When this force is excessive, it may damage the motor/gear and special treatment may be required to strengthen it.

3. Operation in low temperature environmentApplication: Security camera, Electric lock (=fixed use in cold area), etc

Regular operation temperature range of Orbray Motors is -20℃ ‒ 60℃(coreless motor).The motors can be used outside of this range, but it may influence the characteristics and life time. With special treatment, they may operate in up to a -40℃ environment (not guaranteed, and does not apply to all motors), so please inquire accordingly.

4. Low noiseApplication: High-end broadcasting camera, Security camera, etc

Generally, spur gears make less noise than planetary gears. But, some applications such as high-end broadcasting camera require further minimization of operation noise during lens movement. Orbray has a special spur gear (Φ12) to achieve smooth and low-noise lens operation.

5. Low vibrationApplication: Surgical device, Robot servo, Electric nail file, etc

Some applications such as portable high speed spindle (ex: surgical devices)need to eliminate vibration as much as possible for comfortable use by the practitioner. Orbray Motor is designed for relatively low vibration, but it can be further minimized by special treatment.

STEP5

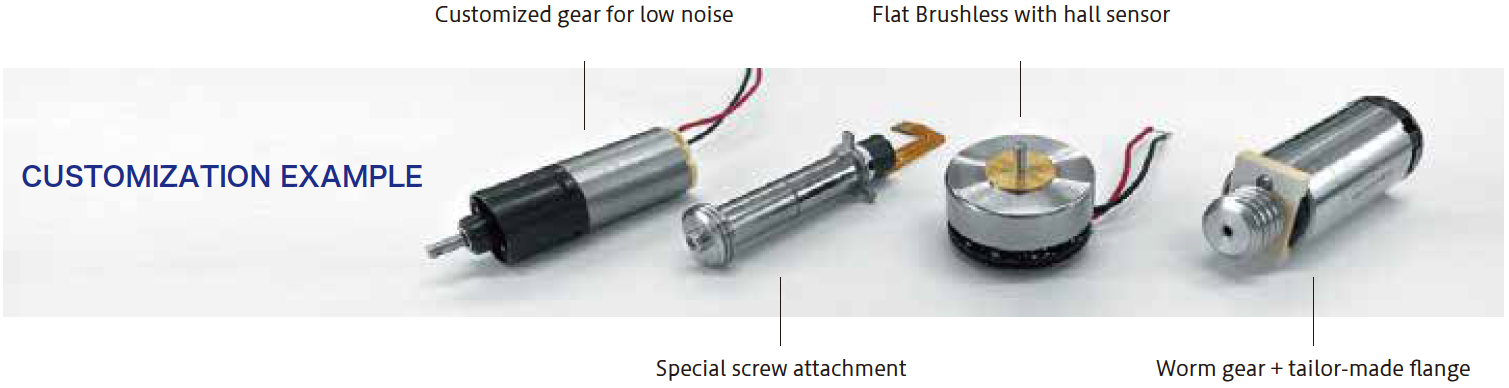

CUSTOMIZATION GUIDEMore than 80% of products provided by Orbray are a customized solution based on each customer's application. With over 80 years of experience, we provide professional support answering to the specific needs of each and every customer.

| CUSTOMIZATION (Level 1 - 3) | ||

|---|---|---|

| LEVEL 1 | LEVEL 2 | LEVEL 3 |

| Output shaft change | Characteristics adjustment | Life time improvement |

| A hole on shaft D cut on shaft Shaft length change Shaft diameter change |

Adjusting torque/speed Low temperature resistance Special gear ratio Low current consumption Noise reduction |

Treatment for long time use |

| Leadwire change | Strength improvement | Special shape / parts, etc. |

| Leadwire change Attaching a connector Extraction strength improvement Leadwire type change |

Increase radial force |

Customized flange Change housing diameter |

| Other special requirement | ||

| Reducing vibration Reducing backlash |

※LEVEL1 - LEVEL3 is for reference only. Please contact our sales representative for details.

TOTAL CUSTOMIZATION

We also propose zero-base total customized solutions based on large-scale confidential business projects. In such cases, an official contract needs to be signed, and R&D costs may be incurred.

Contact

*Click here for detailed inquiries.

*If you cannot find the contact form, please click here.