Unlike conventional connectors, expanded beam connectors provide high durability and stability by utilizing an expanded beam of light. This feature prevents the end-face from contamination even after repeated use of connection and dis-connection, making maintenance easy. The connector is also adaptable to special environments and will remain dependable even in harsh environments.

Expanded beam connection technologyUnder Development

Expanded beams employ a technology that expands the beam for transmission. This technology has several advantages.

-

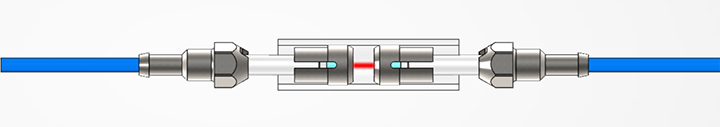

1. Connection made by non-contact spatial propagation

Connectors can be connected to each other by non-contact air gap space propagation. This prevents wear and tear and improves long-term reliability.

-

2. Highly resistant to contamination

Designed to resist contamination (dirt and foreign matter), so it is not affected by the environmental conditions. Easy to manage since end-face cleaning is not required.

-

3. High-precision coaxial (concentricity) characteristics

By utilizing our high-precision processing technology with more than 40 years of experience in ferrule and sleeve manufacturing allows for reduced loss fluctuation in connector tuning.

-

4. Customizable

In-house optical and mechanical design enables customized optical characteristics and size. Sleeves and ferrules can also be manufactured in-house, allowing for a high degree of design freedom.

-

5. Applicable to various connector types

Expanded beam connection technology has been established and can be applied not only to LC connectors but also to a variety of other connector types.

-

6. Adaptation to special environments

Expected to remain dependable even in special environments, these characteristics allow for expanded beam connectors to provide high performance in a wide range of applications and reliability, especially in harsh environments.

Comparison of termination methods

New method

Expanded Beam (Collimated Beam)

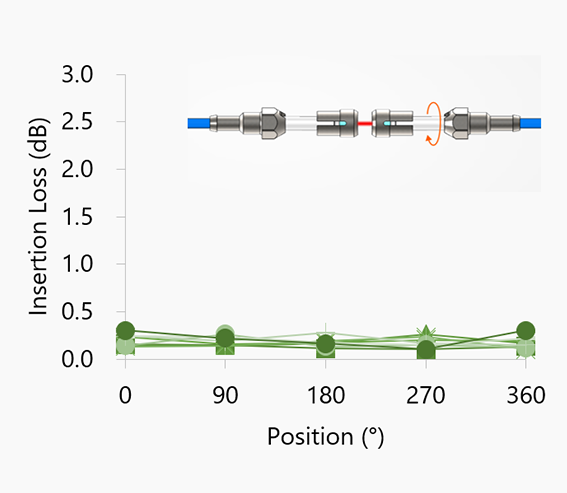

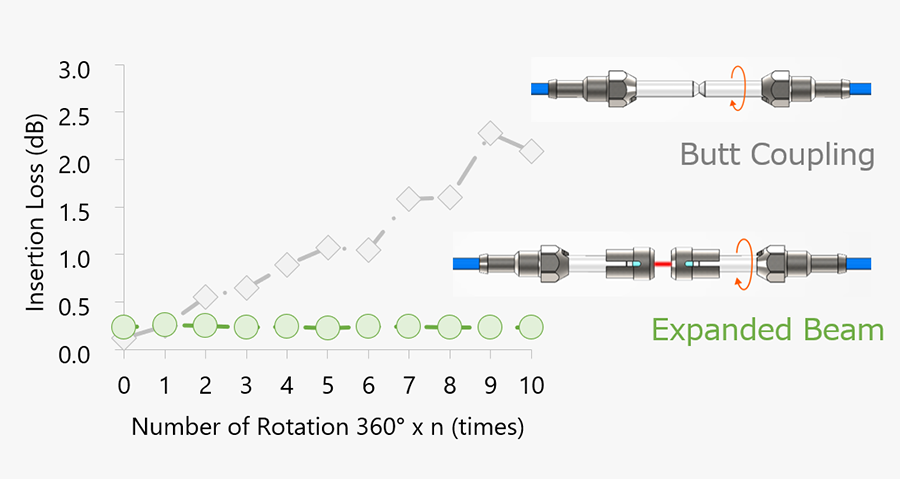

The use of a lens results in a non-contacting spatial coupling of the end faces, which reduces insertion loss variation in rotation movement. It also has the advantage of being less susceptible to end-face damage and contamination eliminating the need for end-face cleaning.

Conventional method

Physical Contact (PC)

Since ferrule end faces make physical contact to each other to form a connection, the insertion loss (IL) is excellent. However, the ferrule is more susceptible to wear due to rotation movement and thus, a higher risk of end-face damage and contamination is present, and the end faces must be cleaned.

Special Characteristics

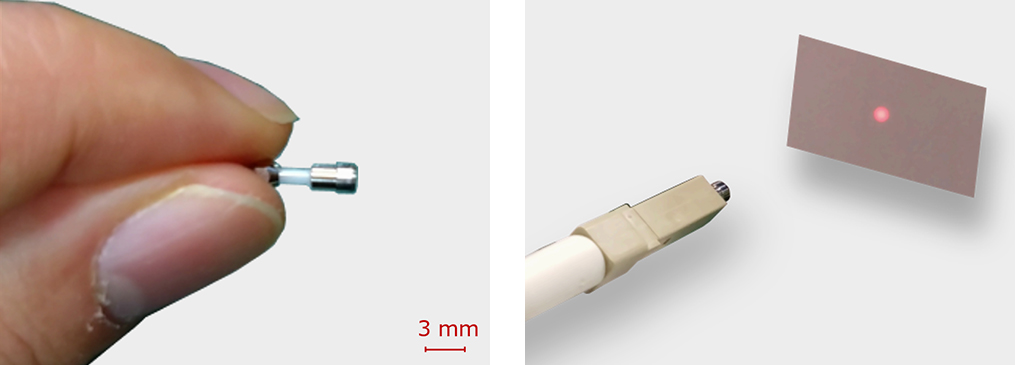

Design Example

Singlemode type (@1550nm)

Radiation angle (1/e2): φ160 μm

・Radiation angle (1/e2): <1°

Multimode type (@850 nm)

・Beam diameter (5%): φ380 μm

・Radiant angle (5%) : <3°

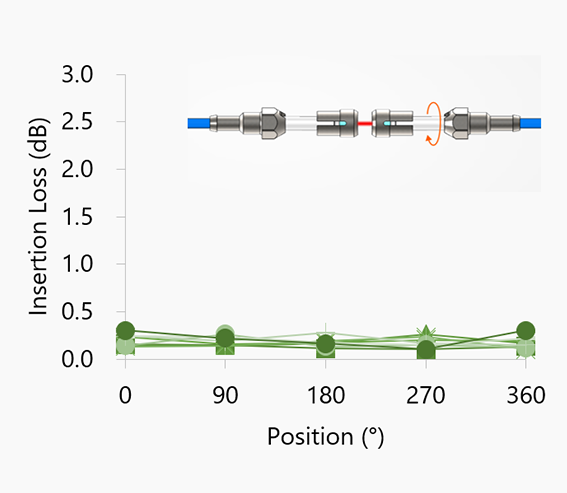

Rotation Loss Variation

Multimode type expanded beam

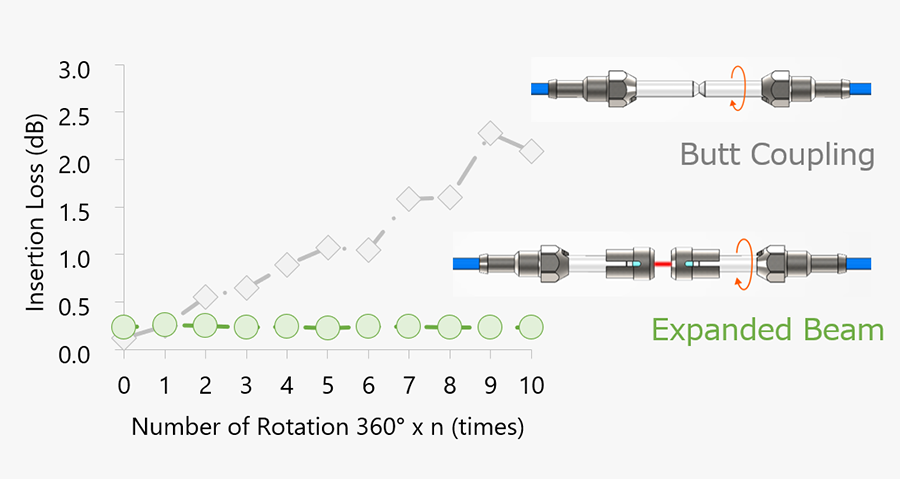

Expanded beam and butt-coupling

Applications

Data Centers

High-speed connections between server racks

Reliable performance in environments with frequent plug-and-unplug cycles

Industrial robots

Optical data transmission through moving parts (vehicle production lines)

Stable operation in high-vibration and impact-prone environments

Marine systems

Reliable data transmission in harsh environments (e.g., subsea cable repeaters)

Ensured performance in high-pressure and high-humidity environments

Medical devices

Detachable optical communication modules (e.g., endoscope systems)

Maintaining clean and hygienic working environment

Aerospace

High-reliability communication (e.g., inter-satellite links)

Stable performance in extreme conditions

Others

Automotive, defense, broadcasting, and imaging equipment