What is a micro motor(ultra compact motor)?

If a "small motor" has an output of 75W or less, the output of a "micro motor" is generally 3W or less. At

this size, even a small-capacity power source such as a dry cell battery can run the motor. Therefore, there

are many DC driven micro motors. There are not any AC micro motors that meet the above definition, which is

most likely because at high currents, such as 100V, there is the risk of the mechanisms inside the

miniaturized motor catching fire or short-circuiting.

Orbray has successfully developed the world's smallest φ0.6mm brushless motor, and 1.5 geared motor. Since the

components of micro

motors are tiny, and the contact life is limited in configurations that use a brush and commutator,

reliability is improved by making the motor brushless.

Orbray has pursued "smallness" as a pioneer of ultra-compact motors for many years by utilizing our unique

"cutting, grinding, polishing" technology. The achievements made addressing such technological challenges

are attracting attention in cutting-edge fields such as medical care, robotics, and measuring instruments.

One example is the hollow shaft motor, which we've used in the Optical Inner Wall Metrology System we

launched on the market.

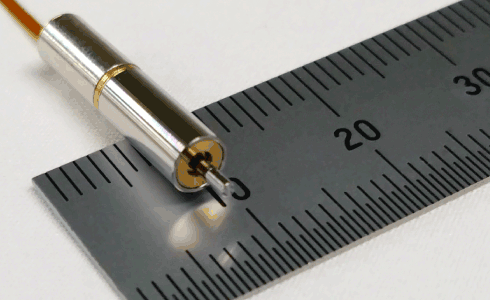

Brushed Motor CMS07-17XX

The brushed motor

CMS07-17XX is Orbray's smallest diameter brushed motor.

Despite its small size, CMS07-17XX has good responsiveness and less rotation unevenness, and one of this

motor uses is medical device such as infusion pump. The motor is required to be small and lightweight

because mainly it is used at home, and also must be reliable due to medical use.

Application Example

- Medical / analytical measuring device

- Optical device

| Products | Dia. [mm] |

Length [mm] |

Nominal Volage [V] |

Nominal | No-Load | Stall | Mecha nical time constant [ms] |

Max. effici- ency |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Torque [mNm] |

Speed [rpm] |

Cur- rent [mA] |

Output Power [W] |

Speed [rpm] |

Cur- rent [mA] |

Torque [mNm] |

Cur- rent [mA] |

||||||

| CMS07-1707 | 7 | 17.5 | 3.7 | 0.14 | 17,100 | 104 | 0.5 | 20,200 | 19 | 0.94 | 571 | 6.8 | 67 |

| CMS07-1714 | 3 | 0.10 | 9,100 | 54 | 0.1 | 11,400 | 14 | 0.47 | 214 | 7.11 | 56 | ||

| CMS07-1726 | 7.4 | 0.14 | 18,600 | 54 | 0.5 | 22,100 | 10 | 0.84 | 283 | 7.48 | 65 | ||

Catalog

CMS07-1707CMS07-1714

CMS07-1726

Geard Brushed motor CMS07-17XXPXX

| Products | Dia.[mm] | Length [mm] | Nominal Volage [V] |

No-Load | Stall | Max. effici- ency [%] |

Option | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Speed [rpm] |

Cur- rent [mA] |

Torque [mNm] |

Cur- rent [A] |

Conne- ction |

Bearing | ||||||

| sleeve | Ball | ||||||||||

| CMS07-1707P4.7 | 7 | 24.9 | 3.7 | 3,377 | 51 | 3.53 | 0.57 | 49 | - | 〇 | × |

| CMS07-1707P22 | 7 | 27.1 | 3.7 | 698 | 62 | 13.87 | 0.57 | 45 | - | 〇 | × |

| CMS07-1707P105 | 7 | 29.3 | 3.7 | 144 | 74 | 54.21 | 0.57 | 41 | - | 〇 | × |

| CMS07-1707P494 | 7 | 31.6 | 3.7 | 36 | 61 | 223.07 | 0.57 | 45 | - | 〇 | × |

| CMS07-1714P4.7 | 7 | 24.9 | 3 | 2,230 | 28 | 2 | 214 | 85 | - | 〇 | × |

| CMS07-1714P22 | 7 | 27.1 | 3 | 460 | 34 | 7 | 214 | 72 | - | 〇 | × |

| CMS07-1714P105 | 7 | 29.3 | 3 | 95 | 38 | 27 | 214 | 61 | - | 〇 | × |

| CMS07-1714P494 | 7 | 31.6 | 3 | 21 | 34 | 110 | 214 | 52 | - | 〇 | × |

| CMS07-1726P4.7 | 7 | 24.9 | 7.4 | 4,380 | 29 | 3.10 | 0.28 | 46 | - | 〇 | × |

| CMS07-1726P22 | 7 | 27.1 | 7.4 | 906 | 35 | 12.00 | 0.28 | 42 | - | 〇 | × |

| CMS07-1726P105 | 7 | 29.3 | 7.4 | 186 | 43 | 48.00 | 0.28 | 37 | - | 〇 | × |

| CMS07-1726P494 | 7 | 31.6 | 7.4 | 41 | 35 | 197.00 | 0.28 | 42 | - | 〇 | × |

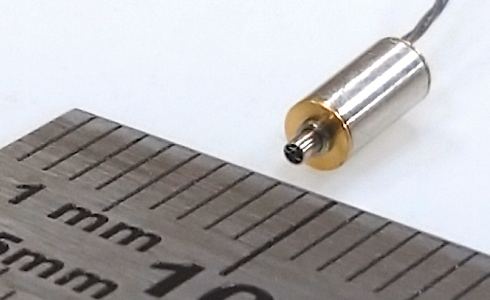

Brushless motor BMN04-0829

| Pro- ducts |

Dia. [mm] |

Length [mm] |

Nominal Voltage [V] |

Nominal Values |

No-Load | Stall | Mecha- nical time constant [ms] |

Max. effici- ency [%] |

Option | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Torque [mNm] |

Speed [rpm] |

Cur- rent [mA] |

Output Power [W] |

Speed [rpm] |

Cur- rent [mA] |

Torque [mNm] |

Cur- rent [mA] |

Conne- ction |

Bearing | |||||||

| sleeve | Ball | |||||||||||||||

| BMN04-0829 | 4 | 8 | 3.0 | 0.01 | 24,200 | 53 | 0.04 | 37,000 | 28 | 0.04 | 100 | 9.2 | 22 | A (sensorless) | ○ | ☓ |

Geard Brushless motor BMN04-0829PXX

BMN04-08

is a φ4mm brushless

motor.

Orbray also offers Φ4mm planetary gears. (Gear ratio: 4.3/18/79/337)

There are only a few companies in the world that can mass-produce 4mm brushless motors.

Orbray produced this motor for large telescope use. This small geared motor was used to control the

position of optical fiber inside of the telescope. Although it has a small diameter, it produces

delicate

movements.

Application Example

- Medical / analytical measuring device

- Telescope

| Products | Dia.[mm] | Length [mm] | Nominal Volage[V] | No-Load | Stall | Max. effici- ency [%] |

Option | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Speed [rpm] |

Cur- rent [mA] |

Torque [mNm] |

Cur- rent [A] |

Conne- ction |

Bearing | ||||||

| sleeve | Ball | ||||||||||

| BMN04-0829P4.3 | 4 | 13.7 | 3.0 | 8,100 | 50 | 0.09 | 0.10 | 8 | A | 〇 | × |

| BMN04-0829P18 | 4 | 14.9 | 3.0 | 1,960 | 50 | 0.37 | 0.10 | 9 | A | 〇 | × |

| BMN04-0829P79 | 4 | 16.1 | 3.0 | 464 | 51 | 1.49 | 0.10 | 8 | A | 〇 | × |

| BMN04-0829P337 | 4 | 17.3 | 3.0 | 103 | 52 | 6.47 | 0.10 | 8 | A | 〇 | × |

Ultra Micro Brushless Motor BMN02-0593

Orbray's micro Motor(Ultra Compact Motor)

Wiring passed through the hollow shaft

Orbray's micro motor BMN02-0593 belongs to the world's smallest class of hollow shaft motors. Since optical fibers can be run through the hollow shaft, it is possible to construct ultra-compact optical actuators, which are expected to contribute to breakthroughs in leading medical and industrial fields, such as OCT* and endoscopy.

Based on this hollow shaft motor technology, Orbray developed an Optical Inner Wall Metrology System for use in the industrial measurement field. This system is capable of 3D measurement of the inner circumference of small-diameter holes in components – data which was previously limited and challenging to collect.

Orbray aims to meet the needs of cutting-edge medical and industrial fields with our hollow shaft micro motor.

*Optical Coherence Tomography = technology that uses near infrared rays to take tomographic images of samples.

Application Example

- Medical / analytical measuring device

- Development of evaluation technology for internal state and progression of wear of important equipment such as infrastructure equipment, vehicles, and aircraft

- Construction of ultra-compact manipulators that have limited wiring space

*It is not available to use BMN02-0593 with standard model brushless motor driver SSD06-R5A and SHSD24-01A.

Please contact us about the dedicated driver for BMN02-0593: SOD12ST

Catalog

Contact

*Click here for detailed inquiries.

*If you cannot find the contact form, please click here.