Electronically commutated sensorless motor, slotless stator design,Hollow shaft

| Gear | |||

|---|---|---|---|

| - | - | - | - |

| Brushless Motor | |

|---|---|

| BMN02-0593 | - |

| - | - |

| Encoder | |

|---|---|

| - | - |

| Driver | |

|---|---|

| SOD12ST | - |

| - | - |

magnet

Specifications

| BMN02-0593 | ||

|---|---|---|

| Rated voltage[V] | 4 | Calculated value |

| Stall torque[mNm] | 0.01 | Calculated value |

| Stall current[mA] | 43 | |

| Terminal resistance[Ω] | 93.00 | |

| Back-EMF constant[mV/rpm] | 0.024 | |

| Torque constant[mNm/A] | 0.23 | |

| Operating speed[rpm] | 100‐6,000 | |

| Direction of rotation | CW/CCW |

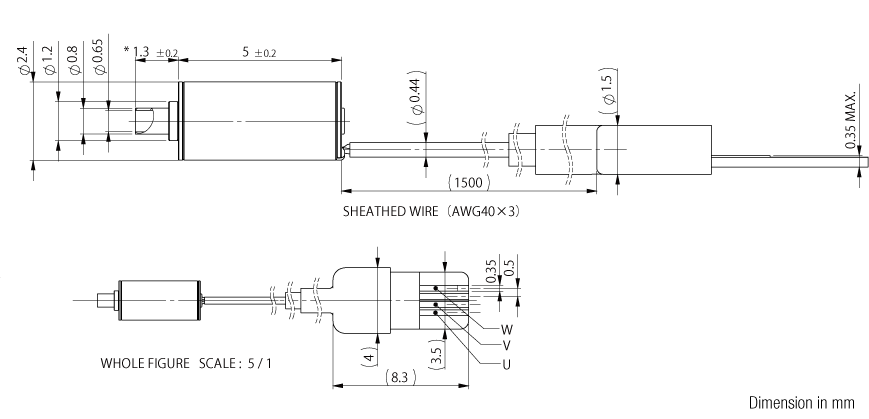

Orbray's micro motor BMN02-0593 belongs to the world's smallest class of hollow shaft motors. Since optical fibers can be run through the hollow shaft, it is possible to construct ultra-compact optical actuators, which are expected to contribute to breakthroughs in leading medical and industrial fields, such as OCT* and endoscopy. Based on this hollow shaft motor technology, Orbray developed an Optical Inner Wall Metrology System for use in the industrial measurement field. This system is capable of 3D measurement of the inner circumference of small-diameter holes in components – data which was previously limited and challenging to collect. Orbray aims to meet the needs of cutting-edge medical and industrial fields with our hollow shaft micro motor.

* Optical Coherence Tomography = technology that uses near infrared rays to take tomographic images of samples.

Application Example

- Medical / analytical measuring device

- Development of evaluation technology for internal state and progression of wear of important equipment such as infrastructure equipment, vehicles, and aircraft

- Construction of ultra-compact manipulators that have limited wiring space