Solid sleeves are mainly used for connecting optical modules and have replaced fiber stubs as connection

components for PD Module in order to provide a stable connection at a low cost.

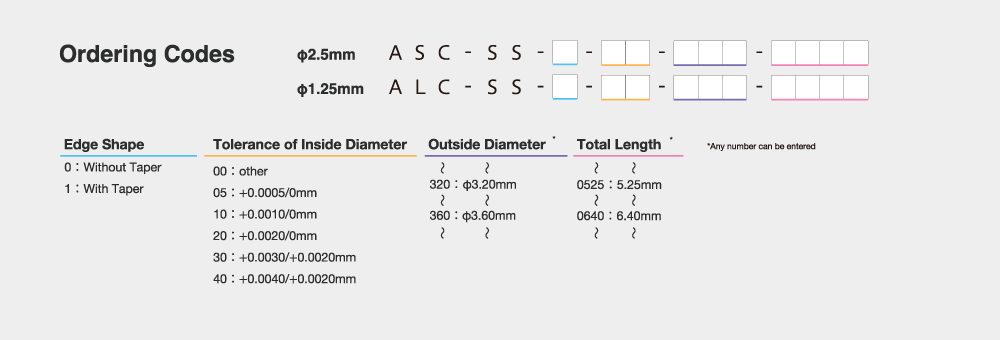

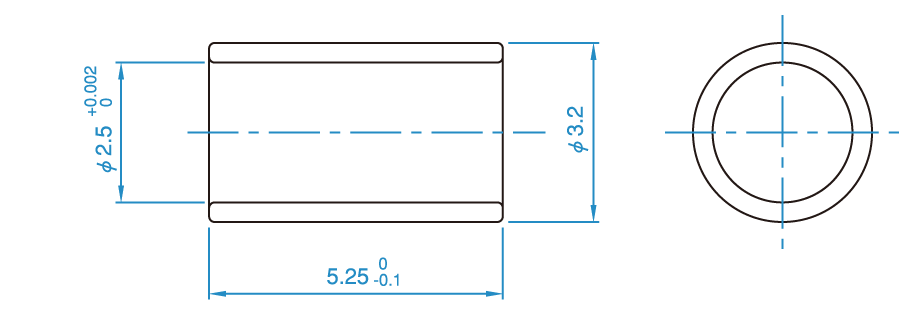

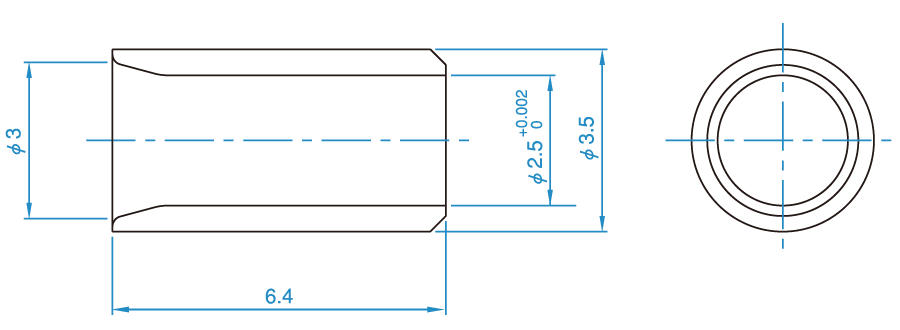

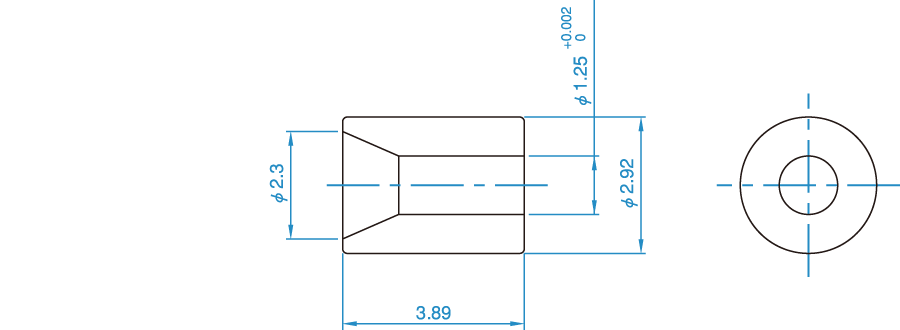

We also supply different configurations of solid sleeves for Ferrule Outer Diameters of φ2.5mm and

φ1.25 mm. There are several sleeve configurations to choose from. One type consists of a tapered

process located on the inside ends of the sleeves in order for entry ease when inserting the ferrules of

the connectors.

We also supply the anchor processed sleeves for plastic insert molding. We can also accommodate to order

the plastic insert molding process itself. In order to function as precision sleeves, the technique is

required to inspect the ID within submicron tolerances using pin gauges. We also manufacture and sell our

own pin gauges as well.

Recently, the manufacture and sales of solid sleeves is increasing for the purpose of strengthening the

tolerance of the side load (wiggle issue) present within optical modules. Therefore, solid sleeves have

now also been expanded in applications not only for PD Module but also for LD Module.

Appearance: Solid Sleeve

- Custom design

- Prototype samples to large volume production

- Taper processing available

Applications

Receptacle

Tx/Rx Modules

Access Networks

Precision Packaging

※Click on the drawings to enlarge.