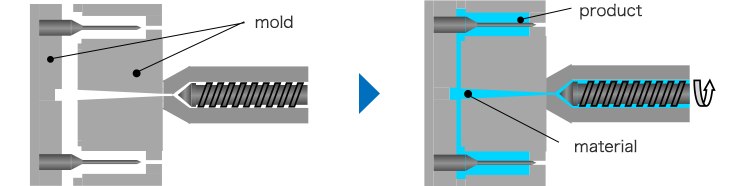

Injection molding

Injection molding is a method of acquiring form by sending heated, melted material into a mold, and then cooling and solidifying it.

It is suitable for mass-producing products with complicated shapes, and is used for most of the plastic products that we see every day.

For ceramic products, a material which mixes plastic with ceramic powder is used.

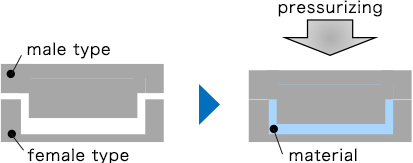

Press molding

Press molding is a method of acquiring form by putting material into a female mold and pressurizing a male mold. It is suitable for production of simple forms like planks.

For ceramic products, material that mixes a plastic binder with ceramic powder is used.

Option

CIP(Cold Isostatic Pressing)

CIP fabrication is a method in which material is put into a rubber mold and dropped underwater, acquiring form by the pressurization of the entire circumference by water pressure.

Since isotropic pressure is applied, this method is used to equalize material density as much as possible.

It is mainly used for fabrication of ceramic products, and uses the same material as press molding.