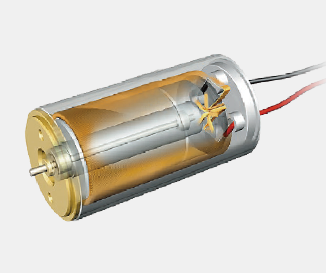

Brushed Motor

Coreless moving coil is light weight, superior in quick starting and stopping (high speed response).

| Efficiency | High efficiency and no iron loss |

|---|---|

| Responsiveness | Very low inertia and able to start/stop quickly |

| Life | Low inductance and long life |

| Control | Linear characteristics |

| Cogging | No magnetic cogging |

| Electromagnetic noise | Low electromagnetic interference |

Brushed coreless motor does not have an iron core, and consists of a cup-shaped core as rotor and a permanent magnet inside the rotor as stator. Brushed coreless motor features the following: Coreless motor features the following:

Features

- Cup-shaped rotor coil is very light weight and has a small moment of inertia, allowing the motor to start and stop quickly.

- Because there is no cogging due to stator-rotor positioning, it features smooth rotation, low noise and low vibration.

- Motor can be made in compact sizes because it is made only of rare earth magnet, coil and rotor.

For the reasons mentioned above, our brushed coreless motor is used in many applications that require high precision, high speed response, as well as compactness and high efficiency.

Issues & challenges in Brushed Motor

The primary factors affecting the lifespan of brushed motors are abrasion due to rotational contact of the brush and commutator, and electric corrosion during polarity switching. While precious metal contact material minimizes the electric corrosion, physical abrasion remains an issue. Changing the brush material to carbon-based can prevent the mechanical wearing, but at the same time, this can increase electric spark noise. In general, brushed motors are not suitable for power motors because they can't accept large flow of electric current.

Orbray presents brushed coreless motors that address these issues equally.

Brushed Motor Standard Model

| Products | Geared Motor |

Dia. [mm] |

Length [mm] |

Nominal Voltage [V] |

Nominal | No-load | Stall | Mechanical time constant [ms] |

Max efficiency |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Torque [mNm] |

Speed [rpm] |

Current [mA] |

Output Power [W] |

Speed [rpm] |

Current [mA] |

Torque [mNm] |

Current [mA] |

|||||||

| CMS07-1707 | Planetary | 7 | 17.5 | 3.7 | 0.14 | 17,100 | 104 | 0.5 | 20,200 | 19 | 0.94 | 571 | 6.79 | 67 |

| CMS07-1714 | Planetary | 7 | 17.5 | 3 | 0.10 | 9,100 | 54 | 0.1 | 11,400 | 14 | 0.47 | 214 | 7.11 | 56 |

| CMS07-1726 | Planetary | 7 | 17.5 | 7.4 | 0.14 | 18,600 | 54 | 0.5 | 22,100 | 10 | 0.84 | 283 | 7.48 | 65 |

| CMS10-1306 | Spur Planetary |

10 | 12.9 | 3.7 | 0.13 | 18,800 | 106 | 0.5 | 22,200 | 19 | 0.88 | 587 | 12.48 | 67 |

| CMS10-1321 | Spur Planetary |

10 | 12.9 | 7.4 | 0.18 | 20,700 | 104 | 0.6 | 26,700 | 30 | 0.79 | 357 | 15.53 | 50 |

| CMS10-1349 | Spur Planetary |

10 | 12.9 | 12 | 0.19 | 21,600 | 66 | 0.6 | 27,400 | 18 | 0.89 | 246 | 14.55 | 53 |

| CMS10-1805 | Spur Planetary |

10 | 18.4 | 3.7 | 0.26 | 11,200 | 121 | 0.6 | 13,200 | 21 | 1.75 | 694 | 8.24 | 68 |

| CMS10-1818 | Spur Planetary |

10 | 18.4 | 7.4 | 0.24 | 14,200 | 68 | 0.7 | 16,500 | 11 | 1.72 | 421 | 9.49 | 70 |

| CMS10-1835 | Spur Planetary |

10 | 18.4 | 12 | 0.31 | 16,600 | 70 | 0.9 | 20,000 | 14 | 1.80 | 343 | 10.35 | 63 |

| CMS12-1506 | Spur Planetary |

12 | 15.0 | 7.4 | 0.44 | 21,900 | 186 | 2.2 | 25,100 | 27 | 3.40 | 1,261 | 15.39 | 73 |

| CMS12-1514 | Spur Planetary |

12 | 15.0 | 12 | 0.51 | 23,100 | 155 | 2.3 | 27,500 | 29 | 3.24 | 833 | 16.70 | 66 |

| CMS12-2004 | Spur Planetary |

12 | 19.2 | 7.4 | 0.43 | 20,400 | 150 | 3.2 | 22,200 | 13 | 5.48 | 1,744 | 8.87 | 83 |

| CMS12-2010 | Spur Planetary |

12 | 19.2 | 12 | 0.45 | 21,200 | 99 | 3.5 | 23,000 | 8 | 5.77 | 1,173 | 8.8 | 84 |

| CMS12-3005 | Spur Planetary |

12 | 29.5 | 7.4 | 0.78 | 11,900 | 163 | 2.9 | 13,100 | 17 | 8.54 | 1,614 | 4.7 | 81 |

| CMS12-3010 | Spur Planetary |

12 | 29.5 | 12 | 0.83 | 13,700 | 121 | 3.7 | 15,000 | 12 | 9.40 | 1,254 | 5.57 | 82 |

| CMS16-2304 | Spur Planetary |

16 | 22.6 | 7.4 | 0.89 | 13,000 | 209 | 3.3 | 14,500 | 24 | 8.78 | 1,849 | 9.31 | 79 |

| CMS16-2309 | Spur Planetary |

16 | 23 | 12 | 0.94 | 14,000 | 145 | 3.9 | 15,500 | 16 | 9.67 | 1,340 | 9.29 | 80 |

| CMS16-2337 | Spur Planetary |

16 | 22.6 | 24 | 0.89 | 14,900 | 73 | 3.8 | 16,600 | 8 | 8.66 | 643 | 9.51 | 79 |

| CMS16-2805 | Spur Planetary |

16 | 27.6 | 7.4 | 1.03 | 8,100 | 146 | 2.6 | 8,900 | 15 | 11.05 | 1,420 | 5.94 | 81 |

| CMS16-2812 | Spur Planetary |

16 | 27.6 | 12 | 1.08 | 8,400 | 97 | 2.9 | 9,200 | 10 | 12.14 | 992 | 5.96 | 81 |

| CMS16-2852 | Spur Planetary |

16 | 27.6 | 24 | 1.02 | 8,700 | 48 | 2.7 | 9,600 | 5 | 10.85 | 465 | 6.13 | 80 |

| CMS16-3302 | Spur Planetary |

16 | 32.6 | 7.4 | 1.63 | 9,400 | 250 | 6.9 | 10,100 | 17 | 26.18 | 3,767 | 4.43 | 87 |

| CMS16-3306 | Spur Planetary |

16 | 32.6 | 12 | 1.58 | 9,300 | 147 | 6.4 | 9,900 | 10 | 24.71 | 2,158 | 4.35 | 87 |

| CMS16-3316 | Spur Planetary |

16 | 32.6 | 24 | 2.36 | 10,600 | 132 | 8.8 | 11,500 | 12 | 28.98 | 1,482 | 4.24 | 83 |

Brushed Motor 4pole High Torque Model

| Products | Geared Motor |

Dia. [mm] |

Length [mm] |

Nominal Voltage [V] |

Nominal | No-load | Stall | Mechanical time constant [ms] |

Max efficiency |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Torque [mNm] |

Speed [rpm] |

Current [mA] |

Output Power [W] |

Speed [rpm] |

Current [mA] |

Torque [mNm] |

Current [mA] |

|||||||

| C4S10-1307 | Spur Planetary |

10 | 13.8 | 4.7 | 0.28 | 13,500 | 136 | 0.7 | 16,300 | 28 | 1.66 | 657 | 4.90 | 63 |

| C4S10-1907 | Spur Planetary |

10 | 19.8 | 7.4 | 0.45 | 14,900 | 119 | 2.0 | 16,500 | 13 | 4.62 | 1,104 | 3.44 | 80 |

Contact

*Click here for detailed inquiries.

*If you cannot find the contact form, please click here.