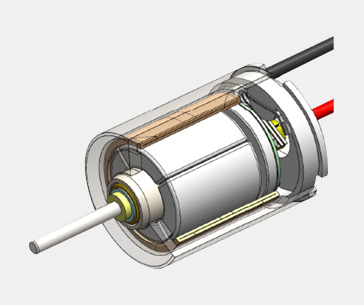

4pole High Torque Motor

By applying 4-pole magnet, effective magnet density area is enlarged, and the torque constant is greatly enhanced.

Features

Effective magnet density area: +30% (Orbray test result)

Total magnetic flux increased +30% from 2 pole magnet.

Torque constant: +60% (Orbray test result)

When running with the same road, current consumption is 35% less than 2-pole magnet motor.

Mechanical time constant: -60% (Orbray test result)

With enhanced torque constant, response speed is also improved by 40%.

As a pioneer in coreless motors, Orbray has pursued development of high torque motors. Generating high torque by enlarging the magnet or inputting a large current has its limitations in terms of heat generation and magnet materials. Orbray tried to increase torque by increasing number of magnet poles form 2 to 4.

By applying a 4-pole magnet, the effective magnet density area is enlarged. As a result, it contributed to a higher torque constant and low current consumption. Moreover, it enhanced mechanical time constant, so even the response speed became quicker.

Using diamond processing technology, a 4-pole magnet processing method has been established in Orbray.

Brushed Motor

| Products | Geared Motor | Dia. [mm] |

Length [mm] |

Nominal Voltage [V] |

Nominal | No-load | Stall | Mecha nical time constant [ms] |

Max. effici ency |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Torque [mNm] |

Speed [rpm] |

Current [mA] |

Output Power [W] |

Speed [rpm] |

Current [mA] |

Torque [mNm] |

Current [mA] |

|||||||

| C4S10-1307 | Spur Planetary |

10 | 13.8 | 4.7 | 0.28 | 13,500 | 136 | 0.7 | 16,300 | 28 | 1.66 | 657 | 4.9 | 63 |

| C4S10-1907 | Spur Planetary |

10 | 19.8 | 7.4 | 0.45 | 14,900 | 199 | 2 | 16,500 | 13 | 4.62 | 1,104 | 3.44 | 80 |

Brushless Motor

| Products | Geared Motor | Dia [mm] |

Length [mm] |

Nominal Voltage [V] |

Nominal | No-load | Stall | Mecha nical time constant [ms] |

Max. effici ency |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Torque [mNm] |

Speed [rpm] |

Current [mA] |

Output Power [W] |

Speed [rpm] |

Current [mA] |

Torque [mNm] |

Current [mA] |

|||||||

| B4S12-2108B | Spur Planetary |

12 | 21.0 | 12 | 1.58 | 13,132 | 275 | 4.5 | 15,320 | 55 | 11.09 | 1,592 | 3.49 | 66 |

| B4S12-2109B | Spur Planetary |

12 | 21.0 | 15 | 1.66 | 16,543 | 288 | 5.9 | 19,300 | 56 | 11.64 | 1,678 | 4.2 | 67 |

| B4S22-3210B | Planetary | 22 | 32.0 | 24 | 9.75 | 6,096 | 358 | 13.9 | 7,000 | 53 | 75.54 | 2,412 | 3.91 | 73 |

Contact

*Click here for detailed inquiries.

*If you cannot find the contact form, please click here.