Industrial applications of sapphire

Although sapphire is best known as a precious stone used in jewelry, it also has many industrial uses thanks to its excellent mechanical, optical, thermal, electrical, and chemical properties. Methods to artificially manufacture sapphire were developed over 100 years ago, and as modern advances have allowed higher quality sapphire to be produced more consistently, the industrial applications continue to increase.

Table of contents [close]

Methods of creating sapphire

Sapphire is a crystal made of aluminum oxide (Al2O3). The mineral name is corundum. Pure corundum is colorless and transparent but tiny amounts of impurities can give it a red, blue, yellow, or pink hue. Corundum that is dark red is known as a ruby, while other colors are often called sapphire. Artificially created corundum of any color except red (including colorless and transparent) is known as sapphire.

A method to synthesize sapphire was developed by the French chemist, Auguste Verneuil, in 1881 and publicized in 1902. In the Verneuil method, aluminum oxide power is heated to 2000 deg C in a furnace to create mist-like droplets of Al2O3. The furnace is then cooled slowly to allow the Al2O3 to accumulate on a seed sapphire particle inside the furnace. In Verneuil's time, it took about 3 hours to produce 10 - 15 carats of sapphire crystal using this method.

Following this, sapphire’s excellent properties gained attention for industrial use. As demand for synthetic sapphire increased, new manufacturing methods, such as the Czochralski, Kyropoulos, crucible, and EFG methods, were developed. In the EFG method, any crystal orientation can be selected. This means c-plane, r-plane, a-plane, or m-plane crystals can be produced as needed. This method has a fast growth rate and produces highly homogeneous crystals.

Exceptional properties of sapphire

One of the greatest properties of sapphire is its high mechanical strength. It is one of the hardest minerals, second only to diamond, and is very durable. It also has a low coefficient of friction. This means when it makes contact with another object, both the sapphire and the object can slide easily without getting scratched or damaged.

Sapphire is also very transparent. It has high optical transparency, not just in the visible light spectrum but also in the UV and IR light ranges (from 200 nm to 4000 nm).

With a melting point of 2040 deg C, sapphire is also very heat resistant. It is stable and can safely be used in high temperature processes up to 1800 deg C. Its thermal conductivity is also 40 times greater than that of glass. Its ability to dissipate heat is similar to that of stainless steel.

Sapphire is also very chemically stable. It is very corrosion resistant and is not damaged by most bases or acids such as hydrochloric acid, sulfuric acid, or nitric acid. It is also able to withstand long exposures to plasmas and excimer lamps. Electrically, it is a very strong insulator. Its dielectric constant is stable, with an extremely low dielectric loss.

Sapphire: not just a jewel

Given its exceptional properties, sapphire is used in many industrial products today. For example, because of its high transparency, hardness, and scratch resistance, it is often used in wristwatches as cover glass and as ball bearings. In recent years, it has found widespread use in smartphone lens covers and fingerprint authentication sensor covers.

Because it can withstand high temperatures and pressures and is resistant to chemicals and plasmas, sapphire is also used as observation windows in testing equipment and space vehicles. Its low dielectric loss and high electrical insulation mean it can be used in plasma generation tubes as well as in halogen lamp tubes, which tend to get very hot.

Furthermore, since it allows light of a wide range of wavelengths to pass through and is resistant to scratches, sapphire plates are also used for the window of IR barcode readers at cash registers, and for in-vehicle infrared sensors that undergo severe vibration. Since sapphire has high thermal conductivity, it is also used for the polarizers in video projectors.

Sapphire tubes and containers that take full advantage of sapphire’s heat, corrosion, and chemical resistance can be very useful. Such containers can be used to store acids and bases while keeping contents visible. Since transparency is maintained in high temperatures that not even quartz glass can withstand, sapphire containers can be used to observe high temperature melts and other processes.

Sapphire shelves are also found in firing setters for firing electronic components and glass. Conventional ceramic and alumina shelf boards can contaminate the chamber due to impurities and degassing, and are prone to warping and deterioration over time. Sapphire does not have these issues.

Furthermore, sapphire's properties make it an indispensable material for various parts used in the semiconductor manufacturing process, such as in carrier plates and handling arms for wafers. It is also used in sapphire rods and tubes that transport liquids, and in chamber windows, lift pins, and other essential parts.

Its high-temperature stability, low thermal expansion coefficient, and high chemical stability make it ideal for epitaxial growth of nitride semiconductors used in the manufacture of blue and white LEDs. Sapphire substrates play an important role not only in LEDs, but also in the manufacture of other various electronic devices, thanks to the excellent electrical characteristics.

Sapphire is also widely used in the medical field for a range of applications such as endoscope lens covers, scalpels, medical plunger pump parts, and hematology inspection filters.

High precision finishing of sapphire

Sapphire must be processed and formed into a shape suitable for the industrial application. Since it is possible to create any cross-sectional growth using the EFT method, a variety of shapes can be manufactured, such as square, round, and tubular shapes. The sapphire can then be drilled, etched, and polished for the intended use. However, this requires advanced processing technology, since sapphire's high hardness makes it difficult to machine.

For example, in order to polish sapphire, simply performing mechanical polishing with diamond abrasive does not result in a smooth surface, so afterwards, the sapphire must be finished by CMP (Chemical Mechanical Polishing) which polishes while softening the surface with a chemical reaction. This makes it possible to obtain a very smooth surface with a step roughness equivalent to one atom.

While Adamant Namiki focuses on single crystal sapphire wafers for high frequency and LED use, Adamant Namiki also support the production of various shapes, such as plates, tubes, and jewelry.

-

Cut of Jewel

-

TIME Asia interviewed President Riyako Namiki

-

Orbray and MIRISE Technologies have begun collaborating on diamond power devices

-

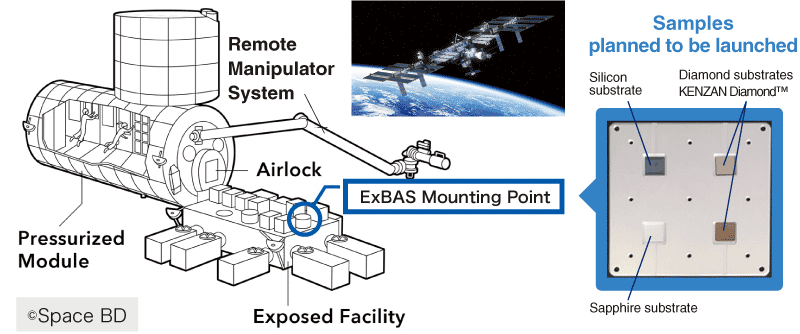

World's First Artificial Diamond Substrate Exposure Experiment in Space

-

Silicon Photonics: Why is it essential for 5G?

-

Introduction to Power Semiconductors: From the basics to applications for each material