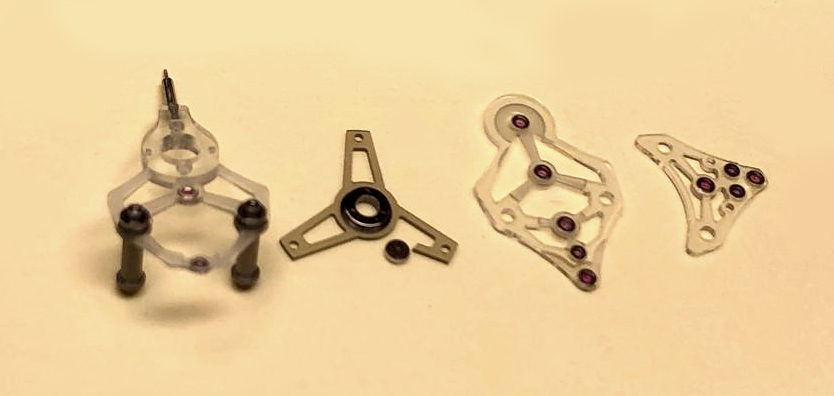

Watch Parts: Beautiful work of craftsmanship -the world's first artificial diamond parts-

Orbray and LEMO Group have many similarities in their history, structure and values. Both are family-owned companies that put their people at the centre of their story, products and technologies. They serve unique markets where the need for quality, reliability, innovation, courage and passion are the keys to success. LEMO Group and Orbray have been partners for many years on various products and projects, always striving to bring the best to the final customer.

Innovation and creativity are ignited when open people and personalities get together with the aim and willingness to produce something new that will be unique and will add value to people’s lives. What happened on the 11th of October 2018 was a sublime connection between like-minded creators from both companies that became the start of the new Project D (DIA).

On that sunny day in Tokyo, the basis for what was going to become an even healthier and more productive partnership was laid down by Calim Bouhadra, CEO of the Rebellion group, and Shoji Namiki, CEO and owner of the Orbray Group. Mr Bouhadra leads three very diverse groups: the LEMO group, worldwide renowned for the quality and specificity of their connectors; the Rebellion Racing team, that has competed multiple times with the TOKYO team for the endurance world championship; and the Rebellion Timepieces brand, a modern and high-quality Swiss watchmaking company. Mr Namiki has led the company founded by his father in 1939 for the last 30 years, growing it to become one of the world leaders in sapphire growth and shaping, and connectivity for optical communications.

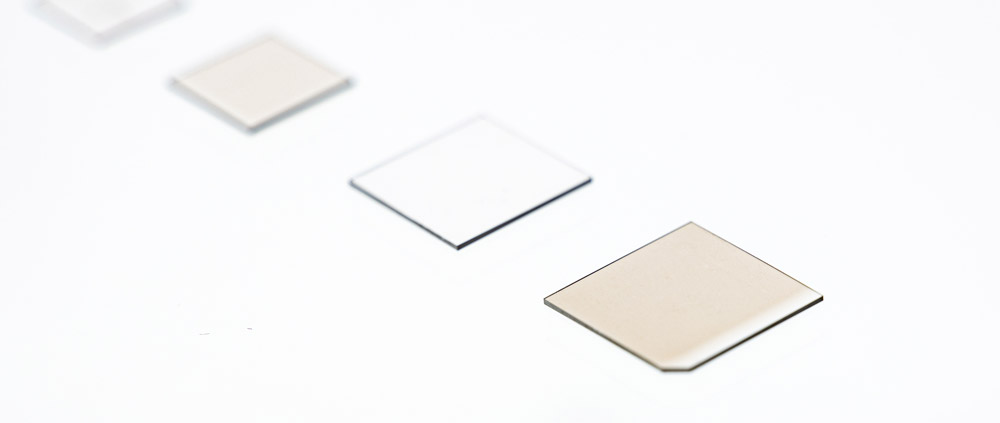

During a daylong meeting with both parties' engineers, some connected over the internet from Switzerland, a considerable brainstorming effort took place to define unique creations that would have made the first pages of magazines. On that day, the Orbray Group presented one of the most advanced innovations of the group, namely the largest artificial diamond wafer ever grown for semiconductor use. Thanks to many years of collaborations with top universities in Japan and around the world, the Orbray Group acquired the knowledge and the patents to grow artificial diamonds in sizes beyond what the other industry players can do, reaching the outstanding 1sq inch in 2019. These lab-grown diamonds (KENZAN DIAMOND) are of the highest purity, encompassing all the incredible features of natural diamonds: the optical properties that make it shine, the hardness, the specific gravity, the durability, and the chemical stability to name a few. With such a large diamond available for the LEMO group, it was a matter of time and the right minds to reach the ultimate idea.

What is one of the most iconic mechanical elements of a Swiss luxury watch? What is the part that adds value and emotions to the most talked-about pieces? The tourbillon. What is the most incredible, hardest to machine, beautiful and unique material used by the watchmaking industry and in jewellery? The diamond.

Thanks to Orbray's technology and the Rebellion group's courage, the challenge was launched: create the world’s first and only tourbillon made of lab-grown diamond.

The challenges for beautiful craftsmanship

Once the project had been decided and approved, it was the time to transform it into a real product. The first part was between the two teams' engineers, to combine their efforts and knowledge to define the tourbillon cage's requirements. Elements like size, thickness, hardness, gravity, elasticity, and many more had to be discussed, analysed and optimised to determine the best possible customer experience. And not only from an aesthetic point of view; the watch had to be validated against the strictest standard of Swiss watchmaking, to be not only mechanically and chronometrically sound, but also keep every detail precisely. The joint team came up with an initial draft shared with the marketing department, and a few changes were made to make it more appealing. Top management support from both companies has been the most critical aspect for a visionary project with a very tight timeline. The watch had to be ready for Baselworld, which meant delivering and testing the lab-grown diamond components by February, and a mere three months to do the development and manufacturing phase.

Every aspect was deeply thought over and discussed, and the regular meetings between Lausanne, Tokyo, Akita and Lonay became the key to the success of Project D.

On the day the watch had to be mounted for testing, another challenge that seems simple but could have stopped the project from being a success came from Switzerland's customs service. Because of the material (lab-grown diamond), the parts took longer than expected to be accepted, which shows that every aspect had to be considered, and the unknowns were everywhere. Material compatibility, manufacturing and polishing, testing, shipping, assembling, chronometry, aesthetic… many things could go wrong, and the combined teams' problem-solving skills were tested to the limit. Overall, an incredible joint effort brought to light the WEAP One, the world’s first tourbillon with lab-grown diamond, which was presented at Rebellion’s booth. The presentation attracted a huge amount of attention from visitors during the Basel fair – even more than expected, which brought a big smile to the faces of everyone involved in Project D. The watch is a beautiful work of craftsmanship resulting from this successful partnership.

-

Introduction to Power Semiconductors: From the basics to applications for each material

-

Orbray and MIRISE Technologies have begun collaborating on diamond power devices

-

Orbray Wins Second Consecutive “Semiconductor of the Year” Award in 2023

-

The Bright Future Being Created by Diamonds

-

The advantages and characteristics of ceramic watches

-

What is the Sapphire?