Production of Sapphire

Many people have attempted to mix elements and produce beautiful synthetic crystals. These attempts happened after the development of modern science when it was discovered that a crystal jewel consists of various elements.

Table of contents [close]

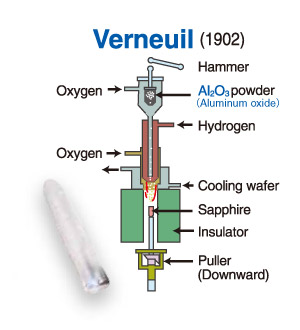

Verneuil Method

In 1881, French chemist, Verneuil, succeeded in the synthesis of a (ruby) crystal with jewel grade quality for the first time. However, the process of manufacturing these jewels was not disclosed until 1902.

Ruby is produced by mixing very small amounts of chrome oxide in with raw material of aluminum oxide powder. This material is placed on the top and gently shaken so that the upper part gradually lowers the powder.

The mixed powders of oxygen and hydrogen are heated up by the flame to approximately 2000 Deg-C, then these powders melt into droplets and accumulate on the top of the seed which dictates the crystalline structure as these droplets grow into a cylindrical ruby crystal.

This method melts the powder material by the oxyhydrogen flame and grows the crystal.

Therefore, it is called the Flame Fusion Method, however, the process takes the inventor's name and is also called the Verneuil Method.

The Verneuil Method used to have a process time of about three hours to produce 10-15 carats of beautiful ruby crystal. However, today the modern equipment has improved tremendously and it have become possible to produce a cylinder shaped ruby crystal with an approximate diameter of 10 cm. The structure is that of sapphire unless the process has problems and different crystal and chemical structures grow.

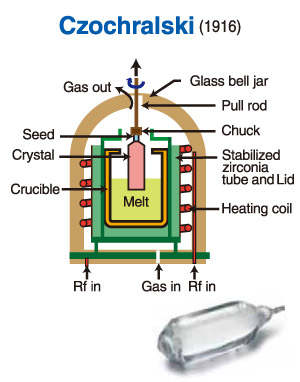

The Fusion Pull-up Method (Czochralski)

This manufacturing method has been invented by a Polish scientist named Jan Czochralski. His method requires a seed crystal to be in contact with the molten alumina. The seed will be in contact with the melt in the crucible, the seed eventually increases in temperature to match the temperature of the melt. The seed is gradually pulled up and cooling of the melt begins which starts the crystallization. This method is called the “pull-up method” or The Czochralski method.

It is necessary to stir the melt, by rotating the growth axis, the distribution of temperature and concentration within the liquid become uniform, and therefore a uniform quality crystal is made. The advantage of this method is that it is easy to observe the growth, easy to judge growth conditions and can it is possible to use a large crucible for the production of a large crystal growth. However, this method has the disadvantage of possibly introducing impurities

from the inner wall of the crucible. The crucible is very expensive for this growth method as well.

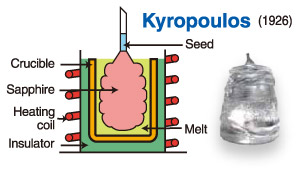

Kyropoulos Method

It's a method really similar to The Czochralski method, but a crystal is grown up by lowering the temperature of the melt slowly. Do not perform the pulling up of crystal, ( it may perform pulling up at slow speed in some cases ), a crystal is grown in melt. Therefore , crystallization is rarely exposed to atmosphere, and that is easy to get a high crystal of the quality future because it is hard to receive thermal stress. Like the Czochralski method, growth in the c-axis direction is difficult but the reduced production cost of wafers come to be produced in Russia.

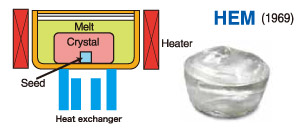

Melting crucible (Heat Exchange Method)

The inventor Fred Schmid worked for the Army Research Laboratory in the State of Massachusetts.

He was requested by the US Army to develop a large sapphire for infrared sensor window of military aircraft sidewinder missile (air to air missile).

He took on that research work for large sapphire window.

The process requires that you place a molybdenum crucible in the center of a large vacuumed furnace, and set a seed crystal in the central bottom of the crucible. Sapphire crackle is loaded on top of the seed crystal, filling up the crucible with sapphire crackle and close by cover. The furnace is then heated up to the melting point of sapphire around 2050 Deg-C by heater which surrounds the crucible. At this time, in order to prevent melting of seed crystal, blowing Helium gas from outside of the crucible and exchange the seed part by helium gas. So, this method is called Heat Exchange Method. According to Fred Schmid’s research report, he has successfully achieved the large-sized sapphire cylinder of which

18.4 cm in diameter, 13.3 cm in thickness and over 15.2 kg in weight.

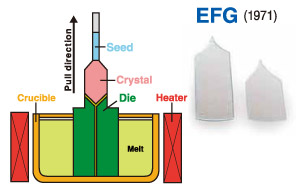

The EFG Method

The EFG method (Edge-defined Film-fed Growth) was reported by Labelle in 1971 and others. The slit called Die is inserted into a crucible, and raise the melt which rose to the die tip and crystallize it.

Because the crystal succeeds the tip shape of the die and grows up, it can get any cross-section.

Because can grow up a plate having a c-plane difficult as for several pieces by the Czochralski method at a time, the feature is that is advantageous to reduction in cost.

There are more information about artificial sapphire in Orbray Co., Ltd. website.