All About Lasers: How they work, their properties, and their uses

Lasers are different from ordinary visible light. Because of their special properties, they are used in a wide variety of applications, from industry to medicine and communications to entertainment.

Table of contents [close]

How are lasers different from ordinary light?

Light is a type of electromagnetic wave. There are many types of electromagnetic waves, such as microwaves, infrared radiation, visible light, ultraviolet light, x-rays, gamma rays, etc. Electromagnetic waves with wavelengths between 360 nm to 830 nm can be detected with our eyes. These are called the visible light spectrum. Electromagnetic waves in this range reflect off of objects and enter our eyes, where we process them into the colors and images we see.

The word laser is an acronym for Light Amplification by Stimulated Emission of Radiation. Lasers are created by exciting the electrons in gasses, liquids, or solids to a high energy state and emitting that energy as light. Lasers have the following properties:

・Monochromaticity (all of the light in a laser has the same wavelength)

・High directivity (all of the light travels in the same direction)

・High coherence (all of the light has the same wavelength and is in phase, i.e., the peaks and troughs are aligned)

・High energy density (because laser light has high directionality, all of the light energy is concentrated in a single direction)

Normal visible light is made up of a mixture of light with different wavelengths travelling in all directions. In contrast, laser light is made of a single wavelength of light and travels unidirectionally. Because laser light travels so straight, it is possible to focus all of the light and its energy into a very small area and increase the density of the transmitted energy.

Normal light is made up of different wavelengths of light that are not in phase with each other, i.e., the peaks and troughs of each wave are unrelated to the others. Laser light, in contrast, is completely synchronized, with the peaks and troughs of the light waves always being in phase. This is known as coherence.

Lasers can be broadly categorized as continuous-wave lasers, which emit light continuously, and pulse lasers, which emit pulses of energy. Very short pulses of light can be emitted.

How laser light is created

Lasers are created through the following steps:

Excitation

When atoms absorb energy from external sources, they transition from a low-energy state to a high-energy state. This is known as excitation.

When atoms are exposed to light, their electrons absorb the light energy and transition from the lowest energy state (the ground state) to a higher energy state. As they absorb energy, the electrons move from their normal orbitals to outer orbitals.

Spontaneous emission

Electrons in their excited states are unstable and continually try to stabilize by returning to a lower energy state. This is called transition.

To return to a lower energy state, the electrons release some energy as light. This release of energy is known as spontaneous emission.

Stimulated emission

When an electron in an excited state is struck by light of the same energy, it emits light of the same energy, phase, and direction. This phenomenon, in which one unit of light produces two units of the same light, is called stimulated emission. This is the fundamental basis for laser light.

Population inversion

In order to generate laser light by stimulated emission, a state in which there are more electrons in high energy states than in low energy states is required. This state is called “population inversion.” This allows more light to be stimulated and emitted than is absorbed, producing laser light.

Amplification

The laser light produced by stimulated emission is amplified by an optical resonator (resonant optical cavity). The resonator consists of two mirrors. A laser beam whose half wavelength is a whole fraction of the distance between the mirrors (a harmonic) is repeatedly reflected between the mirrors. As a result, stimulated emission of light occurs in a chain reaction, generating a large amount of light with the same wavelength and phase, thereby creating powerful laser light.

Below is a typical structure of a resonator for producing laser light. A laser medium, the substance that is the source of the stimulated emission, is placed between optical resonators with mirrors facing each other. The excitation source excites the electrons to a higher energy state (called pumping). There are various excitation sources, such as light, electric current, and chemical reactions, depending on the type of laser.

Lasers capable of nanometer-order ultra-fine processing

Lasers are categorized based on the laser medium. There are solid-state lasers, gas lasers, liquid lasers, and semiconductor lasers.

Solid-State Lasers

YAG (yttrium aluminum garnet) lasers that use YAG crystals as the laser medium, and ruby lasers that use sapphire crystals doped with chromium are examples of solid-state lasers. Solid-state lasers are powerful and able to achieve high outputs compared to their size.

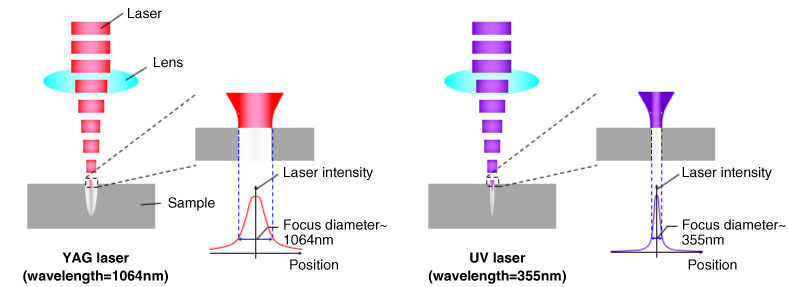

YAG lasers with a wavelength of 1064 nm are common solid-state lasers. They are frequently used in industrial applications such as metal cutting, welding, drilling, fine hole processing, and marking. However, transparent objects such as glass, diamond, and sapphire cannot be processed with this laser, because their transparency renders them unaffected by this particular frequency of light.

The second harmonic of the YAG wavelength is 532 nm. YAG lasers of this wavelength are known as “green lasers” and are used for fine hole processing and silicon wafer marking. The third harmonic (355 nm) and fourth harmonic (266 nm) YAG lasers are called “UV lasers” and are used in ultra-fine drilling, cutting, stereolithography, and similar applications. UV lasers have very high energy, which can be amplified by focusing the laser with a lens to create very high energy densities. UV lasers can therefore be used for very fine processing of transparent materials such as diamond and sapphire.

Gas Lasers

Gas lasers include CO2 lasers that use carbon dioxide gas as the lasing medium, and excimer lasers that use a mixture of gases such as rare gases and halogens.

CO2 lasers have a long wavelength (10.6 μm) and are used for a range of applications such as drilling, cutting, and marking of paper, cloth, plastic, rubber, and wood. By increasing the energy output, they can also be used for welding and cutting metals.

Liquid Lasers

A representative liquid laser is the dye laser. Dye lasers use an organic dye as the medium, in which dye molecules are dissolved in an organic solvent such as ethylene glycol, ethyl, or methyl. They are mainly used for scientific and medical purposes.

Semiconductor Lasers

Semiconductor lasers use semiconductors such as GaAsP (gallium arsenide phosphide), InGaAsP (indium gallium arsenide phosphide), and GaN (gallium nitride) as lasing media. Although semiconductors are solids, they are categorized as a separate laser type. They are widely used in applications such as optical communications light sources, printer light sources, audio player light sources, and laser pointers.

Classification based on oscillation method

Lasers can also be classified according to the laser oscillation method. There are two types of lasers: continuous wave lasers that emit laser light continuously, and pulsed lasers that emit light in pulses. Pulsed lasers are further classified into microsecond, nanosecond, picosecond, and femtosecond lasers according to the pulse length. Machining performance varies with each pulse length. For example, a femtosecond laser with a pulse length of approximately 100 fs (femtoseconds) can perform nanometer-order ultrafine processing without thermal effects.

Uses of Lasers

Lasers are used in a very wide range of fields and applications.

For example, in the medical field, lasers are used in medical tools such as laser scalpels, as well as in medical treatments. In communications, high-capacity, high-speed optical communications cannot be achieved without lasers. In the construction field, measuring instruments using lasers are used to make sure structures are level and to measure distances between features.

Lasers are also used in many industrial applications.

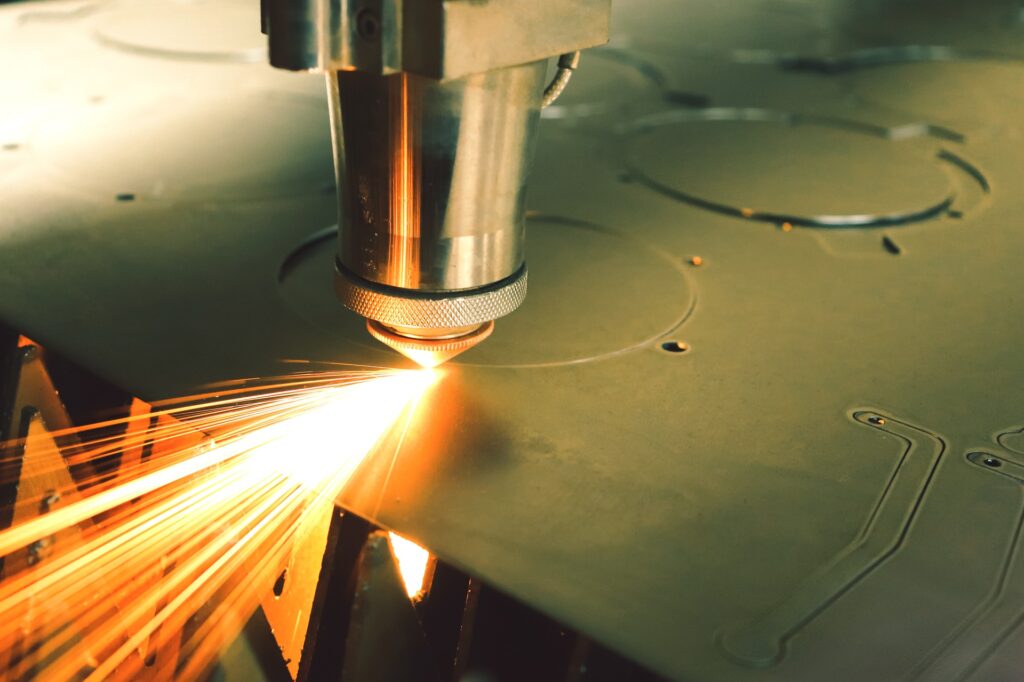

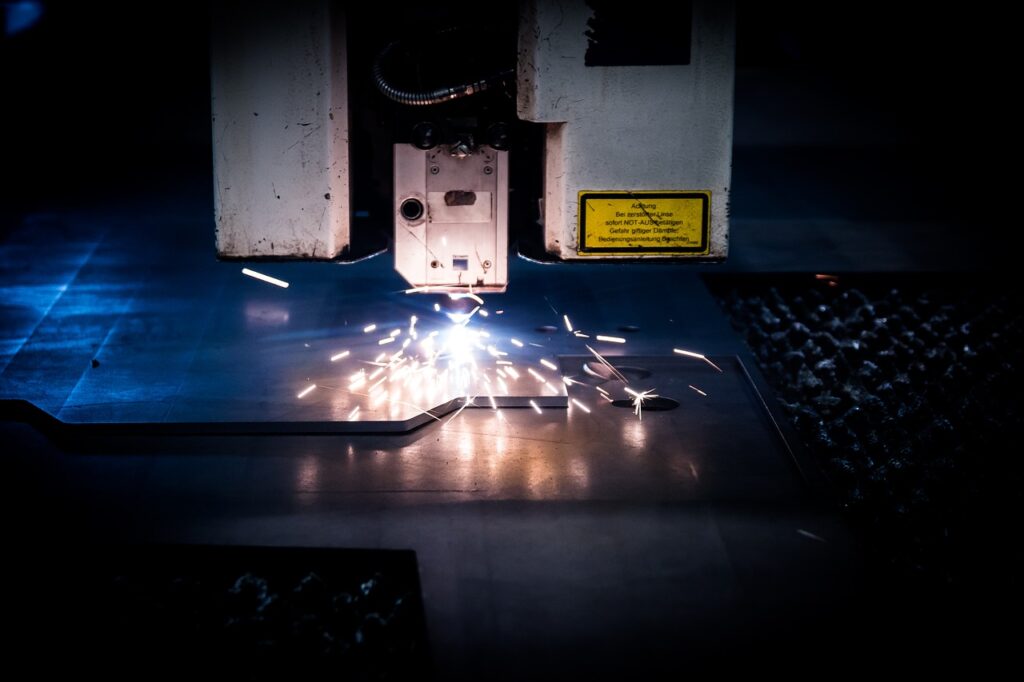

Lasers can be used in instruments that make very exact measurements of length, detect the presence or absence of flaws, and discern missing parts while performing very precise measurements quickly. Lasers are also used for various processes such as cutting, marking, drilling, and welding.

Laser processing is especially ideal for microfabrication of extremely hard materials such as diamond, sapphire, quartz glass, and ceramics, as well as materials that are prone to cracking and chipping.

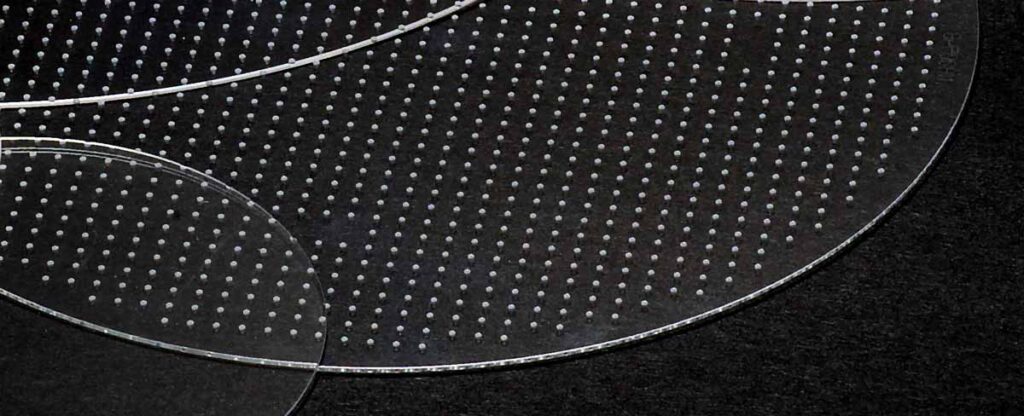

For example, pulse oscillation UV lasers with a wavelength of 355 nm can be used to create micro-holes in transparent materials with high hardness such as diamond and sapphire. For sapphire, holes with a diameter of 60 μm and an aspect ratio of 30 can be drilled. With a pulsed laser, the material is irradiated for a very short time. This makes it possible to obtain a smooth processing surface while minimizing the process deterioration layer that can be caused by thermal effects.

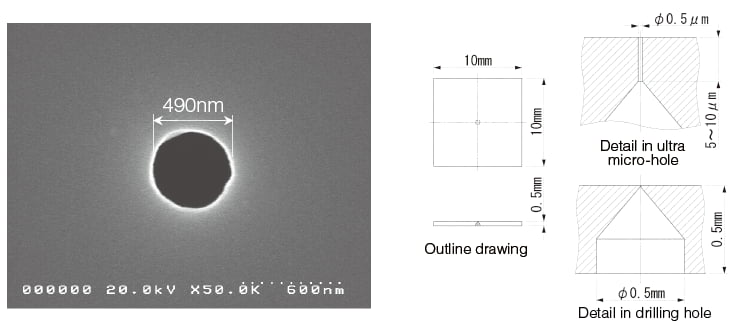

Furthermore, if a femtosecond laser with a pulse length of 100 fs is used, the laser irradiation ends before any heat is transferred to the material. As a result, nanometer-order ultra-fine processing is possible without cracks or debris (substances that are melted and vaporized by the laser and redeposited on the processed surface) caused by heat. A hole diameter as small as 0.5 μm can be achieved with aspect ratios up to 100. Surface roughness of Ra ~ 0.01μm with no work-affected layer can be achieved.

-

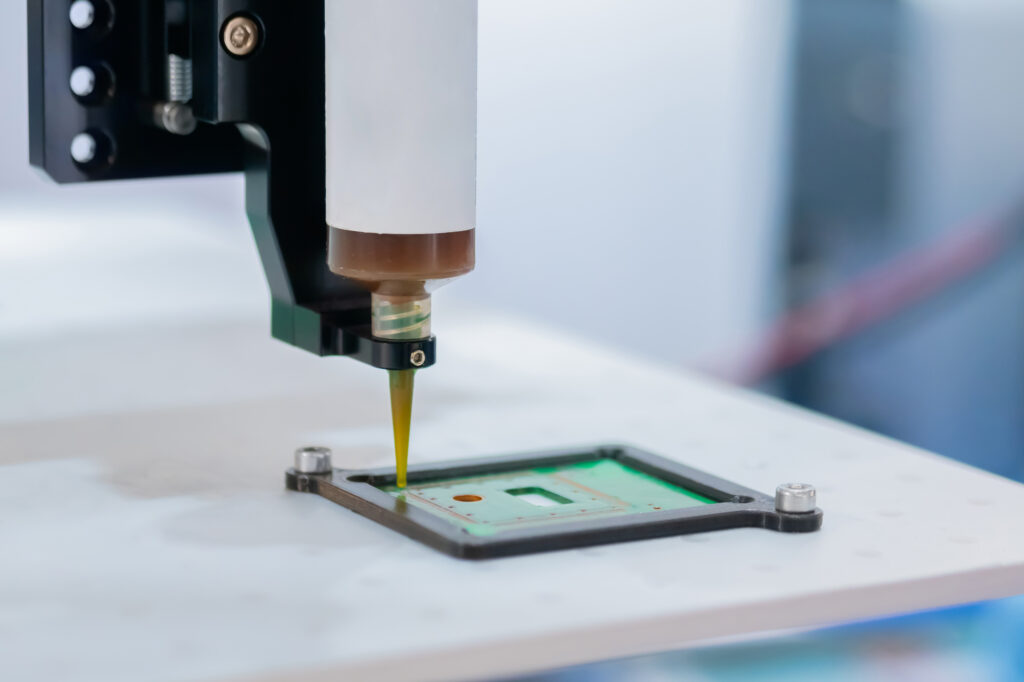

Dispenser Nozzles: Applications for dispensing liquids and selecting the right one

-

History of Orbray crystal glass [Story of Watch 3]

-

Surface polishing technologies - Essential technologies for semiconductor, MEMS, and LED manufacturing

-

Ceramic substrates and raw materials

-

Applications of microwave energy: Microwave heating

-

What are Diamonds?: Synthesis of Diamonds