Jewel bearings: Orbray and the watch industry [Story of Watch 1]

Table of contents [close]

The birth of Japanese-made watches that kept accurate time

Our involvement in the watch industry began in 1949 with jewel bearings.

Back then, watches had a manual winding mechanism that only lasted 1 hour even when fully wound. It was very common for these watches to gain or lose 5 minutes over the course of a day.

A domestic watch manufacturer in Japan introduced technology from Switzerland to reduce resistance in the speed reduction mechanism, which led to the birth of Japanese-made watches that kept accurate time.

Start of production of watch bearings

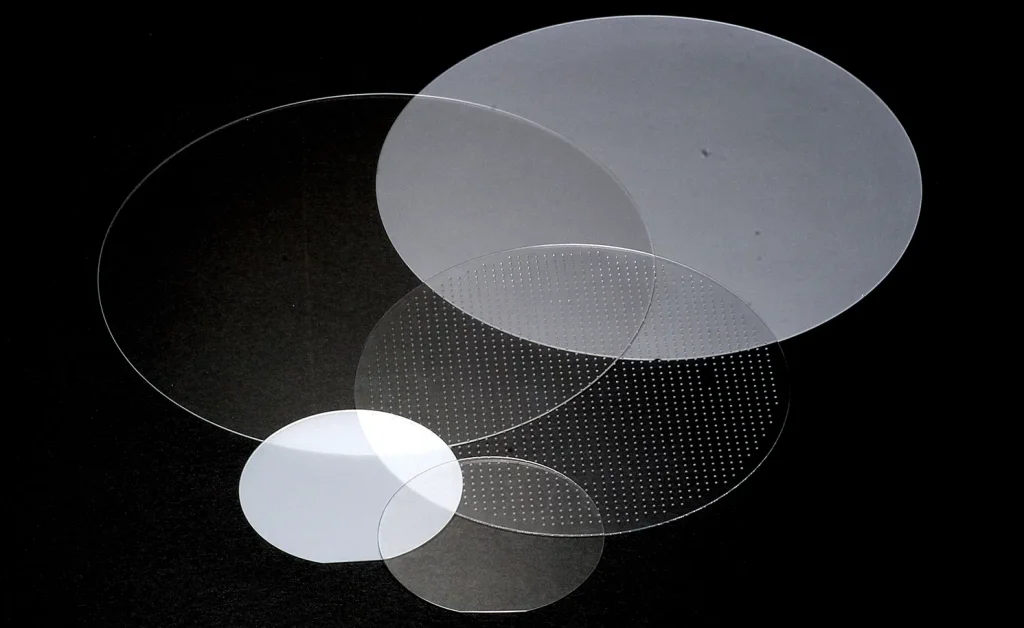

At the time, there were no manufacturers in Japan who specialized in processing the jewel bearings used for the watch movement. Orbray, with pre-existing technology and expertise in manufacturing jewel bearings for wattmeters, was able to quickly start production of watch bearings.

The movement of a watch can keep time more accurately by using a large number of bearings, for example 17 or 24 ruby jewels.

Establishment and development of bearing processing technology

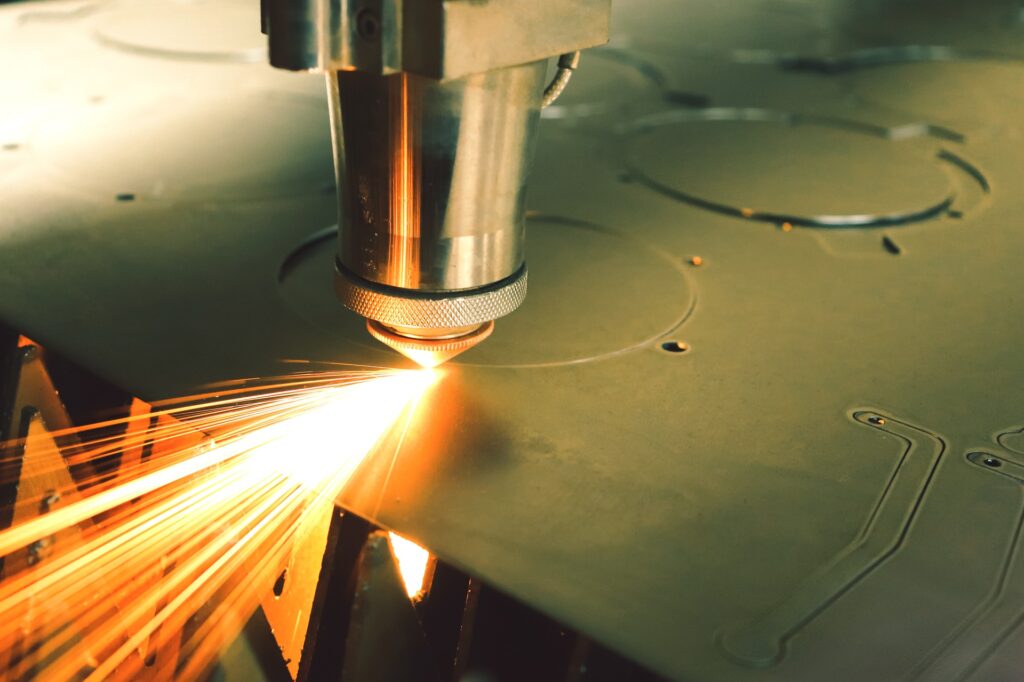

In the early 1970s, Orbray purchased 20 laser machines - the latest technology at the time - for drilling micron order holes in jewel bearings, resulting in increased production efficiency.

Later, with the development of quartz watches and the emergence of higher-torque electric stepping motors, the utility value of jewel bearings decreased. In response, Orbray developed molding techniques for alumina ceramics, leading to the establishment of ceramic bearings.

Even today, we as a watch component manufacturer have continued launching unique watch parts.