Diamond and Microridge Stylus

Table of contents [close]

Nude diamond stylus is the king of the reproducing stylus - made of natural diamond

A reproducing stylus is quite important parts because it is to touch with the groove of a record directly. The area in which stylus is to contact with a record groove is only a couple of hundred-thousandth square centimeter. For example, if you just use spherical stylus on a record with typical tracking force, it’ll be equivalent with 3 ~ 6 tons in weigh if we convert the pressure to record groove.

By the way, there are quite many of people who should have an experience to be stepped on by high-heels. It is still 25kg per 1c㎡. Now you can imagine how the stylus pressure to the groove is heavy.

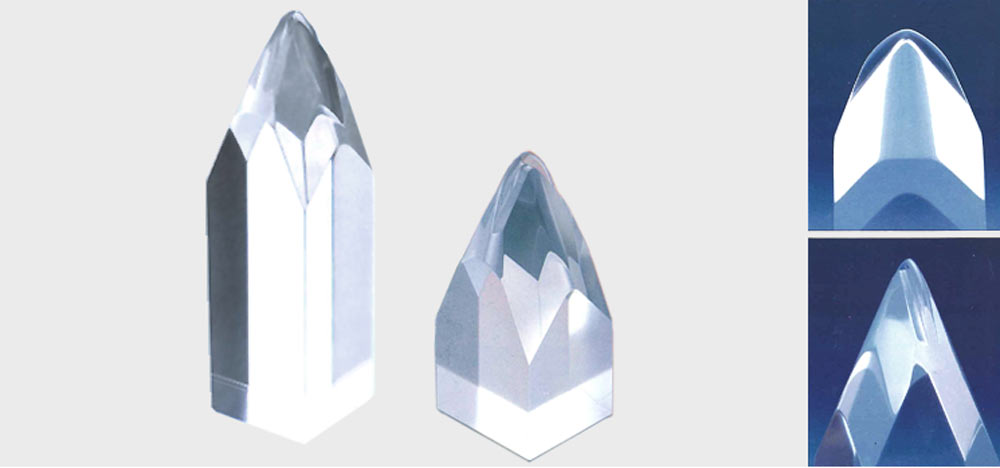

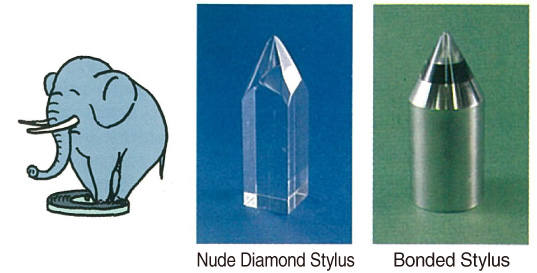

From the above explanation, a groove of a record is easy to warp. It may facilitate to wear the stylus faster due to some frictional heat and dust. Therefore, the material of a stylus had been improved all the time. It’s changed from iron stylus to, tungsten, sapphire, diamond in terms of hardness. The most superior material in hardness is solid diamond, so to speak, “Stylus which made of Nude Diamond” uses a natural diamond, price becomes an expensive for itself. Therefore low cost stylus was developed called “Bonded stylus.”

It is, in short, diamond only for contact area, economical metal for shank part. Earlier, an iron was used but it weighed much, it made an effective mass bigger in cantilever unit, also it became the cause to reduce the resonant freq. in higher range. Afterwards, a titanium bonded stylus was developed and the reduction of effective mass of a bonded stylus was improved. Lately, a bonded stylus with an artificial diamond was put on a market. However, the stylus made of nude diamond with natural one is superior to bonded type stylus by far in terms of polishing, lightweight properties, wear resistance. Furthermore, we got a chance to show our Takumi-waza which was a consecutive type, i.e., stylus and cantilever was made of a diamond. It drew a great deal of attention.

Quadraphonic record, that offered great stereophony, produced current high performance stylus.

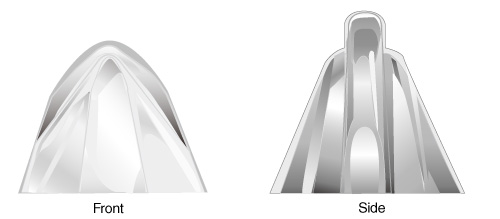

The MicroRidge stylus has a minimal radius and a belt-like contact area a few μm in width and height. A conventional stylus with a minimal radius worn out and became the radius bigger and deteriorated in a short while due to friction during playing, slow down the performance. MicroRidge, however, has a strong to the wear and can keep the initial performance in a good shape. In producing MicroRidge stylus, our cutting-edge technique of polishing made it possible. The stylus which has a minimal radius like the above MicroRidge demonstrated, it is viable to lead a further development of recording technology with a probe.https://orbray.com/en/product/jewel/product/stylus.html#mrstylus2

Features

- High Resolution

- Superior in transparency

- Good sound localization

- Superior in a realistic presence

- Glow of sound

- Less noise

This is the final episode of the Story of Record Stylus series.

More than 100 years have passed since the birth of the record, and efforts to reproduce the original sound have been made constantly. In the meantime, the audio equipment that plays it has made remarkable progress.

By the way, in record playback, the performance of audio equipment is important to maximize the sound information, but the performance of the playback needle that picks up sound information directly from the record is even more important. Regenerated needles that started with iron needles and sapphire round needles have also evolved into elliptical needles and line contact needles, and their tracing ability has improved dramatically. It is now possible to maximize sound information. Behind this was the development of technology for processing “natural diamonds” with extreme precision.

The explanation of the record needle is also available on this page.

Stylus Tip

-

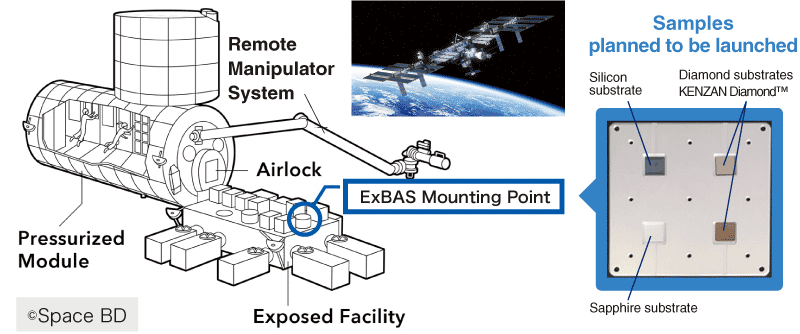

World's First Artificial Diamond Substrate Exposure Experiment in Space

-

Launch of the world's first large12-inch high-quality sapphire wafer

-

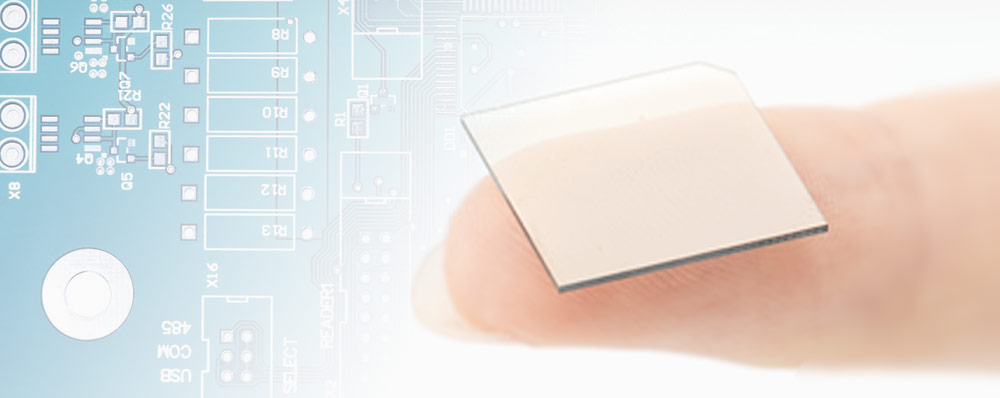

High-quality and Large-diameter Diamond Substrates

-

What are Diamonds?: Synthesis of Diamonds

-

History of Orbray crystal glass [Story of Watch 3]

-

Ultra-Polishing of Sapphire along the c-Plane