What are Porous Ceramics and how are they different from regular ceramics?

Ceramics are solids made of non-metallic materials such as zirconia and alumina which are shaped and hardened by firing in a furnace oven at elevated temperatures. They are known for their outstanding chemical stability as well as high heat resistance, corrosion resistance, and electrical insulation properties. Porous ceramics have all the benefits of regular ceramics plus additional desirable features due to their unique structure. These unique features can be exploited to create vacuum chucks to mount electronic parts, chemical filters, and heat and radiation shields.

Table of contents [close]

The Structure of Porous Ceramics

Ceramics are made by shaping a mixture of non-metallic powders such as zirconia and alumina and hardening them at elevated temperatures in a furnace oven. This method creates exceptionally fine and complex shapes while maintaining high heat and corrosion resistance. They also have exceptionally good electric insulation properties and never corrode or rust. Ceramics can be as hard as diamonds but unlike diamonds, they can be shaped into any desired shape before the firing process. Industrial parts such as cutting and polishing tools and bearings, electronics parts such as ceramic insulators and IC, as well as medical devices such as dentures are some applications of this versatile material.

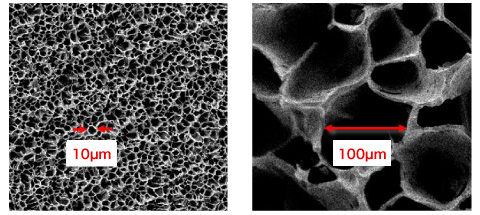

While broadly referred to as porous ceramics, this category of materials encompasses a wide variety of substances and structures. Porous ceramics can be made of alumina, silica, zirconia, and many other materials, and pore sizes can vary greatly, from a few angstroms (Å) to several hundred micrometers (μm).

These materials have the same strength, rigidity, heat resistance, and chemical stability as conventional ceramics but are much lighter because they have a large number of pores that are filled with air. The pores also make the heat capacity and thermal conductivity exceedingly small.

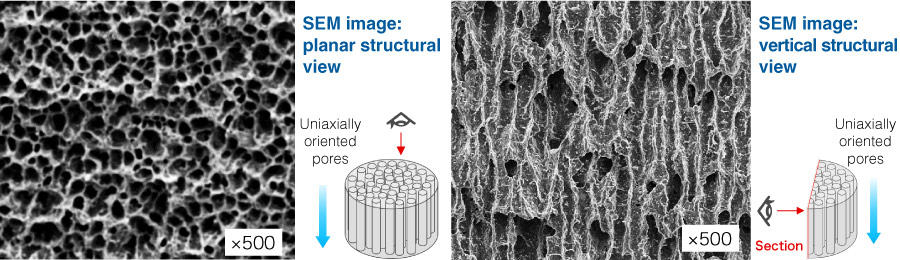

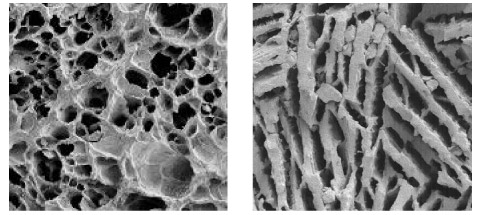

Pores within these materials can be connected together (open pore structure) or closed off and independently dispersed (closed pore structure). Some porous ceramics feature a random mix of open and closed pores, while others have pores that are aligned linearly. Pore size, configuration, and porosity (the number of pores in a given area) can be controlled to suit a wide range of functional needs.

Zeolite and diatomaceous earth are examples of porous materials that occur naturally. Honeycomb-shaped porous structures used in catalysts, and apatite used in artificial teeth and bones are some examples of synthetic porous structures.

Features and Applications of Porous Ceramics

These characteristics allow ceramics to be used in a wide range of applications. Due to their rigidity and high structural stability, and because air can flow through the pores, porous ceramics are used to make vacuum packing for electronics equipment to hold electronic components and semiconductor wafers in place during processing. Ceramics for vacuum packing can be made very flat and smooth through special polishing techniques and are indispensable for holding components firmly in place during precision processing. In addition, instead of suction, air can be blown out of the porous ceramic to slightly levitate components off the surface so they can be transported easily.

In addition, due to their high strength and low weight, ceramics can be used to make equipment and buildings lighter. Because they are tolerant to high heat, ceramics can be used in and around equipment and processes that reach elevated temperatures. Ceramics can also repeatedly absorb water and be dried out. They can be used as humidity control tiles in construction projects.

Porous ceramics can have pores as small as a few dozen micrometers, significantly increasing the surface area of the material. These tiny pores can be used for separating, selecting, and adsorbing substances. By controlling the uniformity and porosity of open pores, it is possible to allow gases or fluids to pass through stably, while also offering effective moisture absorption and humidification properties. Exhaust gas filtration, air purification, dust collection, and drinking water purification are some applications that take advantage of this feature of porous ceramics.

Because ceramics are highly heat-resistant, products made from porous ceramics can be reused many times. Solids, liquids, bacteria, mold and other undesirable materials captured by porous ceramics can be cleaned or burned off and dried at high temperatures for many cycles.

Production of High-Quality Porous Ceramics

Porous ceramics are made by hardening ceramic powers at elevated temperatures just below their melting point to prevent densification. However, there is typically a trade-off between density and rigidity. Generally, increasing the number of pores can result in lower rigidity, depending upon the manufacturing method. The production of high-quality ceramics requires precise control of the powder mixture, firing conditions, and other factors. The powder mixture, firing conditions, and other factors must be precisely controlled to produce high-quality ceramics. Such fine control of the process allows for pore sizes, and range of sizes to be controlled. Pore shape and structure of the ceramic can also be controlled. To create ceramics with pore sizes of just one micron to several dozen microns with pores arranged in a unidirectional pattern while maintaining high porosity, the dispersion of particles and shrinkage of the ceramic in the baking process must be controlled at extremely elevated levels. Ceramics made in this way demonstrate both high porosity and high rigidity (able to support 10,000 times its own weight). They can even be made lighter than conventional resin sponges while maintaining high strength and porosity. Furthermore, it is possible to create a densified layer on the outer surface of the porous ceramic which allows even highly porous ceramics to be grasped easily, making them easier to handle.

Due to their superior performance characteristics, porous ceramics are used in industrial and construction applications, and increased application for environmental protection is expected soon.

Orbray’s Porous Ceramics

Orbray’s Porous Ceramics are not made by the conventional method of creating porous bodies by manipulating the powder sintering conditions. Orbray’s method therefore enables the creation of ceramics with pores oriented in any desired direction. As a result, they feature fine, uniform pores aligned linearly in predefined directions, with the majority being interconnected, open pores that extend to the exterior. This innovative structure overcomes the conventional disadvantage of lack of rigidity associated with porous bodies compared to dense ceramics, allowing for the coexistence of strength and high porosity.

Pore sizes can be controlled from several microns to approximately ten microns, depending upon the customer’s needs. Other difficult ceramics can also be created and produced using our various expertise and experiences.

Please feel free to contact us directly.

-

Fiber Optic Connector types and applications

-

Industrial applications of sapphire

-

Introduction to Power Semiconductors: From the basics to applications for each material

-

Biomaterials: Features and challenges for commercialization

-

Orbray Wins Second Consecutive “Semiconductor of the Year” Award in 2023

-

What is LiDAR? How it works, technologies, and applications