Introduction to suction nozzles and collets

As products in our daily lives become smaller, thinner, and lighter, the electronic components within them are also getting ever smaller. Along with this trend, the need for enhanced functionality and performance of these components is also growing. Consequently, the number and density of electronic components on circuit boards are increasing. In order to inspect, package, and mount such minute electronic components and parts, tiny suction nozzles and collets that transport them are becoming increasingly important.

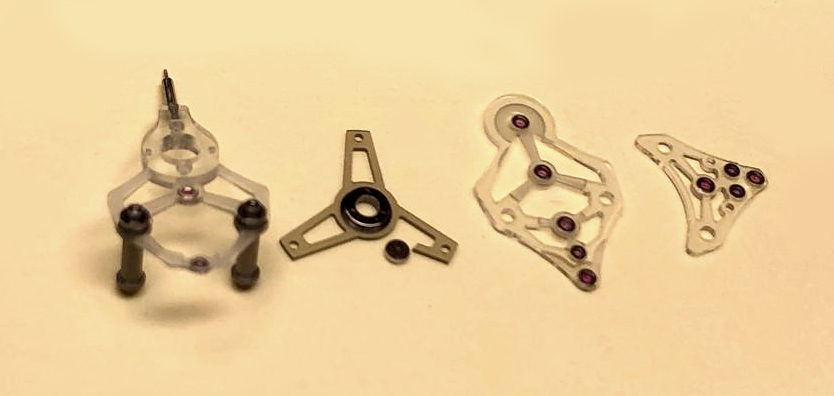

Orbray offers customized nozzles and collets tailored to the specific needs and specifications of our customers, taking full advantage of the extensive expertise in the cutting, grinding, and polishing of precision jewels that we have been developing and refining since our founding in 1939. In particular, we manufacture suction nozzles and collets using materials that are challenging to process, such as industrial jewels like single-crystal ruby and sapphire, as well as ceramics and carbide. These materials are widely used in the production process of miniaturized products.

In recent years, with the trend of electronic devices like smartphones, tablets, and notebook PCs becoming increasingly smaller and thinner, the semiconductors, electronic components, and optical parts used in them have become so tiny that they can no longer be reliably handled by human hands. For example, common chip sizes of ceramic capacitors used in electronic devices by major chip manufacturers around 2018 were the 1608 chip (1.6 mm x 0.8 mm) and the 1005 chip (1.0 mm x 0.5 mm). However, due to the challenges in obtaining these sizes at the time and the need for improved functionality, there was a push to increase packaging density. This led to the adoption of even smaller 0603 chips (0.6 mm x 0.3 mm) and 0402 chips (0.4 mm x 0.2 mm). More recently, the production and practical use of even tinier 0201 chips (0.2 mm x 0.1 mm) have been advancing.

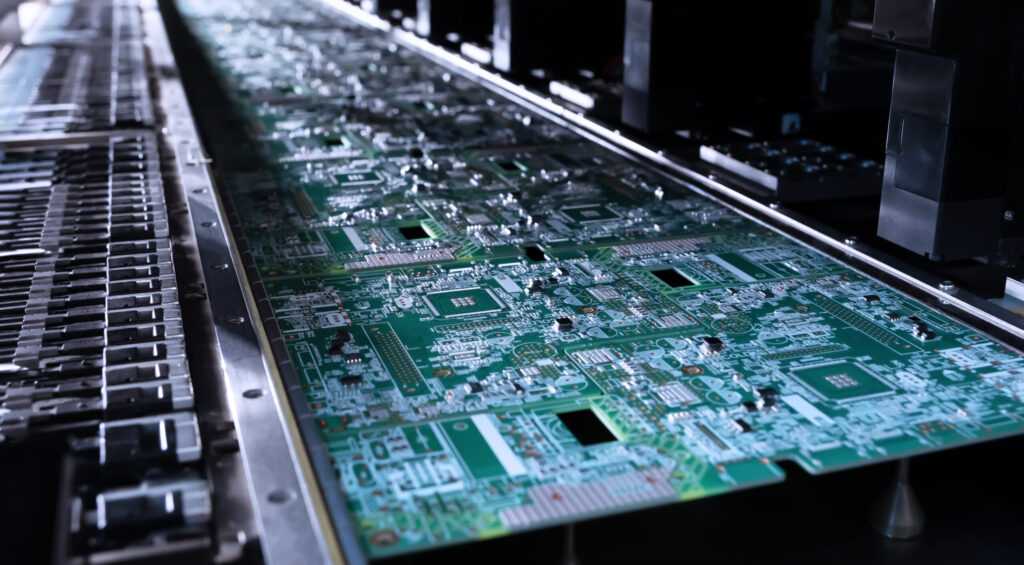

It is difficult and time-consuming to manually place microchips one by one. Therefore, manufacturers of chip transport equipment have developed high-speed transport equipment, one of which is a chip mounter. Also called an electronic component mounter (Photo 1), a chip mounter is a device primarily used to mount these microchips quickly and accurately onto printed circuit boards.

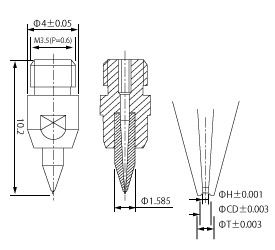

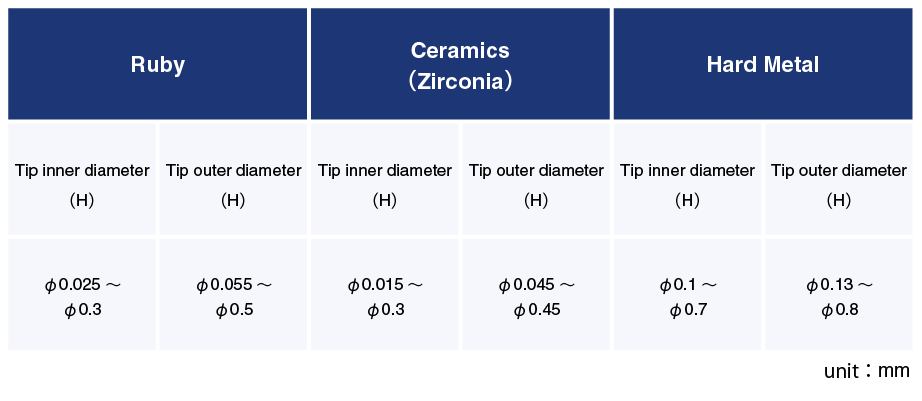

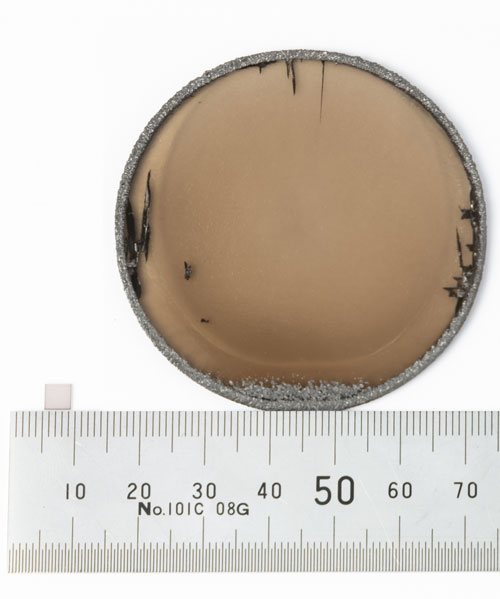

This chip mounter uses a suction nozzles and collet to pick up tiny chips, using image recognition for precise positioning accuracy, and mount them onto circuit boards. Furthermore, suction nozzles and collets are crucial for machines that rapidly transport and mount small-diameter solder balls (approximately 30 µm in diameter), as well as equipment that accurately aligns microchips, and automatic microchip inspection devices. The precision machining of the suction nozzle or collet tip is vital, ensuring it matches the size and shape of the targeted components precisely. Additionally, because these components come into physical contact with the parts that they handle, they need to be made out of materials that are highly durable and resistant to friction and bending. Orbray specializes in processing a wide range of such materials, including single-crystal ruby and sapphire (hardness Hv 2000) – the second-hardest industrial gemstones after diamond – as well as ceramics and carbide. We offer a selection of suction nozzles and collets (Photo 2) that cater to user specifications, alongside a variety of custom nozzles.

In addition, while processing micro-holes in metal is difficult, by utilizing materials like ruby, sapphire, and ceramics, Orbray can create micro-holes with inner diameters as small as 15 μm at the tip. This enables us to control the inner diameter size with precision up to the 1 μm level.

Metal nozzles are prone to wear and bending at the nozzle tip. However, Orbray’s suction nozzles, which are made of ruby, sapphire, and ceramics, are highly wear-resistant, do not bend, and can accurately pick up and transport fine chips reliably.

-

Watch Parts: Beautiful work of craftsmanship -the world's first artificial diamond parts-

-

Success in mass production technology for ultra-high-purity 2-inch diamond wafer; expected to spur realization of quantum computing

-

What is an audio accessory? An overview and detailed explanation of products [Part 2]

-

The Feature of Jewelry

-

Crystal of Jewel

-

Cleavage of Jewel