How small motors allow a robot to walk with a natural gait

Orbray's Future, Vol. 5

On January 1, 2023, we changed the name of our company,

Adamant Namiki Precision Jewel Co., Ltd., to Orbray Co., Ltd.

Coreless motors are important for smooth robot movement

Adamant Namiki products are often used in places that are not outwardly visible. This means that it is rare for us employees to be able to highlight our products to others. One exception is our coreless motors, which are used in humanoid robots and robotic dogs. Although you cannot see the motors themselves, the unprecedented naturalness and smoothness of the movements showcase our technical abilities.

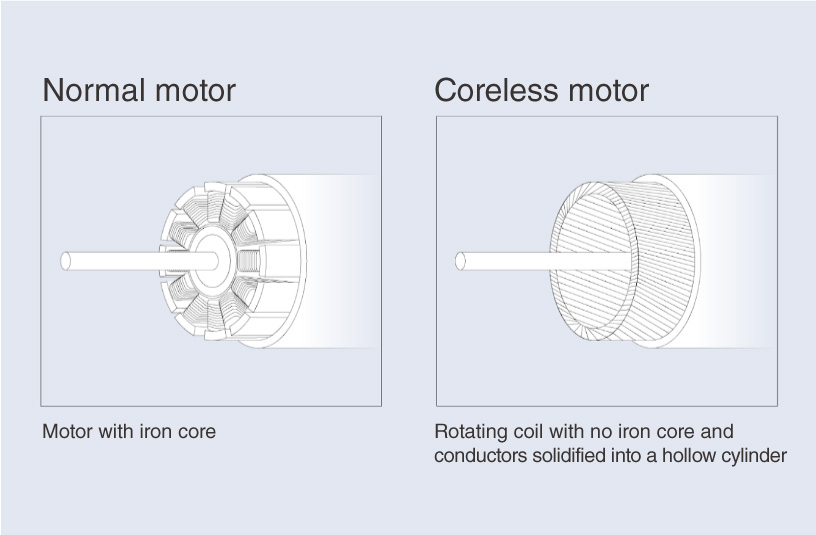

What are coreless motors? Normal motors, like those used in plastic models, have iron cores that are wound with copper wires, and which rotate when activated. Coreless motors have a completely different structure, using a basket-shaped coil of copper wire that rotates. As the name suggests, there is no core.

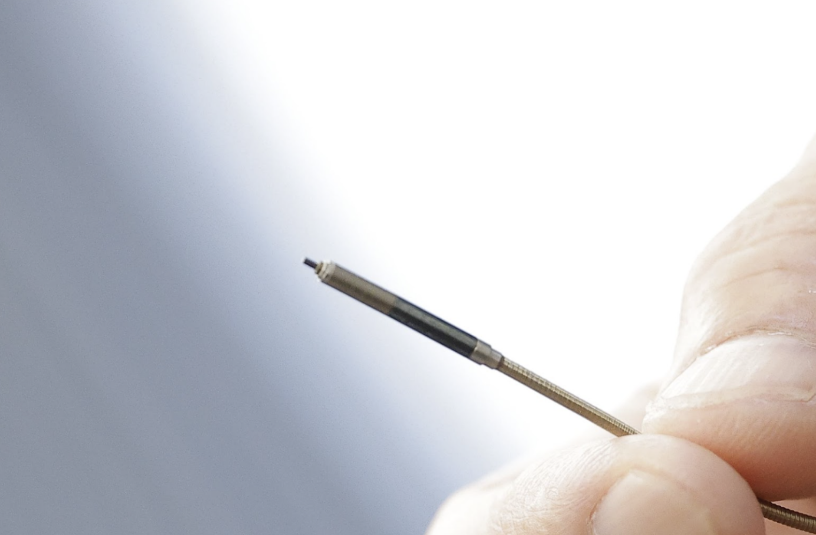

Coreless motors last longer than normal motors and have much smoother movements. Most importantly, they can be miniaturized. Adamant Namiki procured a patent for miniature coreless motors from a German company and proceeded to miniaturize them further. We currently mass-produce coreless motors as small as 4 mm, but have succeeded in making ones as small as 0.9 mm.

History of coreless motor development derived from phonograph cartridges

Motors may seem like an unusual product for a company specializing in industrial jewel and optical communications components. However, we derived our motors from our development of phonograph cartridges that used diamond styli (needles) and other technologies.

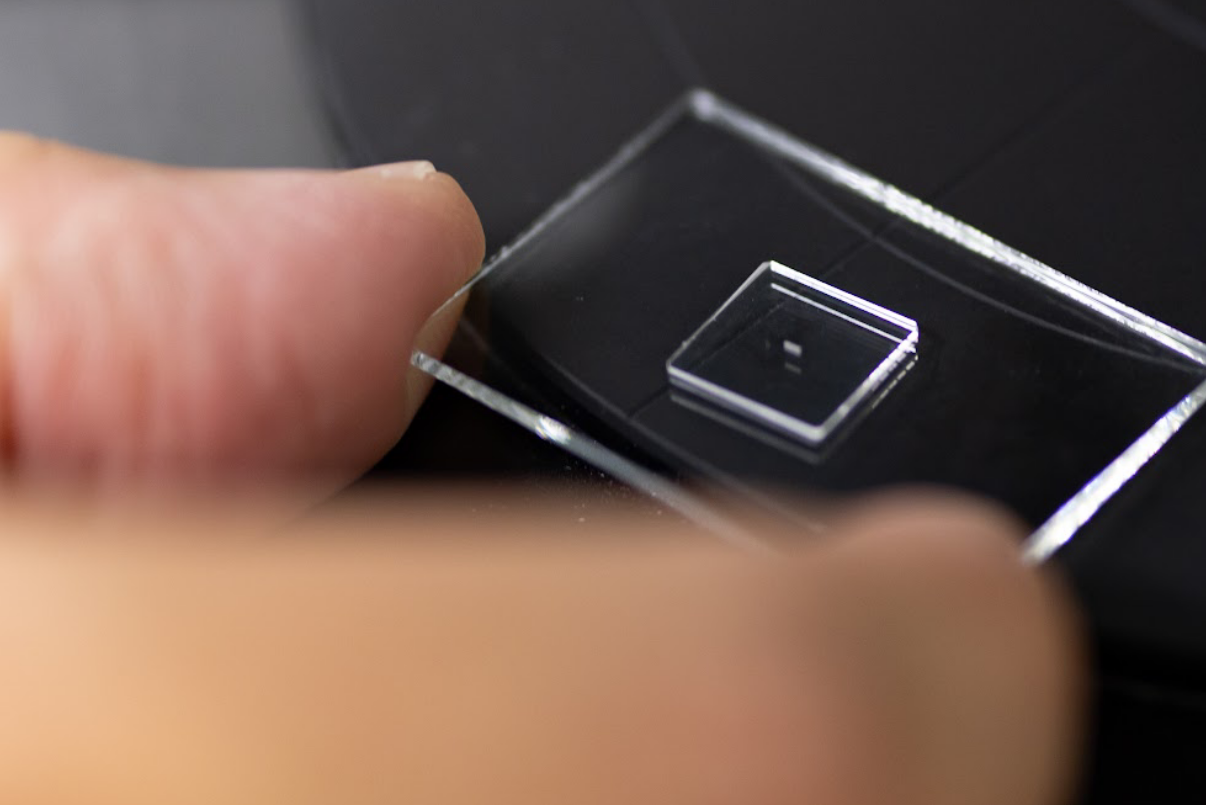

To make a phonograph cartridge, a tiny diamond stylus is attached to the end of an aluminum tube, with a fulcrum at the center of gravity. A magnet is attached to the other end of the cartridge. As the stylus picks up the pits and grooves in the record, the magnet and the coil convert these mechanical movements into electrical signals that are amplified by the speakers. To produce the best sound quality, the magnet has to be light but also very strong.

We applied ourselves to this issue and developed a rare earth magnet that was 10x stronger than what was available at that time. However, the amount of magnets needed to supply the market for phonograph cartridges was very small, so we started looking for other applications for very light, very strong magnets. This led us to motors, and coreless motors in particular.

There are only a handful of coreless motor manufacturers in the world. Among them, Adamant Namiki is the only company capable of producing such small motors. In 2019, we successfully developed our “optical inner wall metrology system.” The apparatus uses a 0.9 mm coreless motor and is capable of measuring the inner surface of a 1.1 mm bore. In recognition of its impact in changing conventional wisdom about what was thought to be possible, we were awarded the Small and Medium Enterprise Agency Commissioner's Award.

Despite their small size, our motors are powerful. This makes them ideal for use in medical equipment, camera lenses, and surveying equipment. Japanese manufacturers dominate the global market for lenses used by media broadcasters around the world, and the motors used in all of these lenses are made by Adamant Namiki. Even though they are small, they have very fast response times and are so quiet that lens noise is not a concern during filming. These characteristics have led to highly positive evaluations of our products.

The story of the development of servo motors for robots that support the smooth movements of "aibo " and "RoBoHoN”

Adamant Namiki brushless motors are also used in RoBoHoN, a humanoid robot developed by Sharp that is even able to make phone calls, as well as in Sony’s robotic dog, aibo, to articulate its joints.

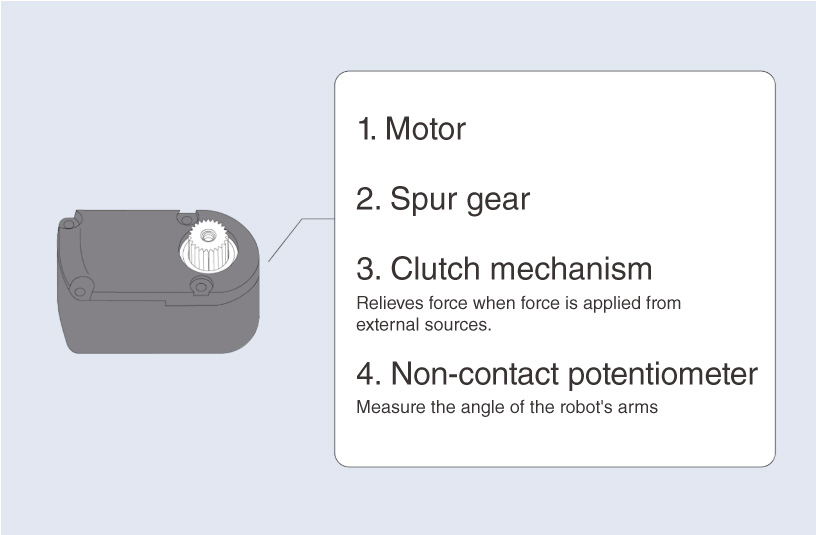

During the development of RoBoHoN, we were originally asked just to provide the motor part of the servo motor. But as the project proceeded, we were asked to develop and provide the entire servo motor. We used a Φ10 mm DC brushless motor to create a compact yet powerful built-in servo.

Servo motors consist of 1) a motor, 2) gears, 3) a clutch assembly, and 4) a non-contact potentiometer. Due to the limited space in RoBoHoN, the arrangement of the gears had to be reimagined to achieve miniaturization. A clutch assembly was required to release excessive external force and prevent damage to the motor and robot. Taking a completely innovative approach, we created a clutch mechanism with a spring to meet the defined requirements.

Servo motors are controlled by programs, and are essential components for robots and automated machines. This was a brand-new field for us at Adamant Namiki. RoBoHoN has 13 motors, all of which have to be controlled in a coordinated manner, so it required very close collaboration with Sharp. Our development team from the Tokyo head office and our factory in Aomori teamed up with Sharp’s Hiroshima factory to take on the challenge. After a lot of hard work, we were able to obtain a patent for this small “robot servo” motor. These servo motors are now used in many communication robots.

We have also developed and started mass production of our own robotic hand (K3HAND) using the robot servos developed for RoBoHoN. The hand can be attached to the end of an articulated robot arm to manipulate objects and perform a wide variety of tasks. We designed a hand that uses eight servo motors to manipulate three fingers. This allowed us to create a lightweight and compact product that is capable of delicate, more human-like movements. As we experience falling birth rates and labor shortages, K3HAND is expected to play an active role in robots that collaborate with humans in the near future.

Sony's robotic dog, aibo, is also equipped with Adamant Namiki’s brushless motors. The aibo project was being carried out in secret by Sony, so during the development discussions, we were only told that they needed a small but powerful motor, with almost no other explanation about its use. The day Sony announced the new product was the first time we learned that the motor we had been developing was for aibo. It was an unforgettable moment!

The motors used in aibo are also servo motors, but the technologies used in RoBoHoN and aibo are completely different. The aibo servo motor is a four-pole motor. Normally, magnets only have two poles. Magnets in aibo’s motors have four poles. This generates a large amount of power with less input. Adding two poles may sound simple, but in reality, it cannot be done without high-precision machining technologies like those at Adamant Namiki.

The future of motors continues to evolve

Motors will continue to become smaller, faster, more responsive, and more powerful. Technology that controls or commands the movements will also likely evolve, augmented by the introduction of encoders, drivers, and artificial intelligence. Adamant Namiki is also developing technologies for motors (and robots) to hold their positions without energy input. That means a robot will be able to stay in position supporting or holding something without any electricity usage.

We at Adamant Namiki are looking forward to the evolution of robots. There will be more and more situations in the future where robots can help humans in our daily lives, such as assisting human movement, augmenting legs and hips in situations where strength is required, and working together at production sites where there are labor shortages. Although RoBoHoN and aibo are machines, they have the power to heal the human mind. We take pride in our contribution to the development of servo motors that allow robots to move more naturally and smoothly and be useful in various situations in our lives.

Furthermore, due to the global trend of decarbonization, motor-powered electric vehicles will become more widespread. We will continue to do our best to ensure that the motors we develop play a significant part in the realization of an environmentally friendly and sustainable society.

Other Columns

Vol.4

Photonics Division Products Sales Dept.

The technology to make a hole of

0.01 mm or smaller in synthetic jewels – how is this useful?

Vol.6

President and CEO Riyako Namiki talks with Executive Vice President Osamu Wada