History of Orbray crystal glass [Story of Watch 3]

Table of contents [close]

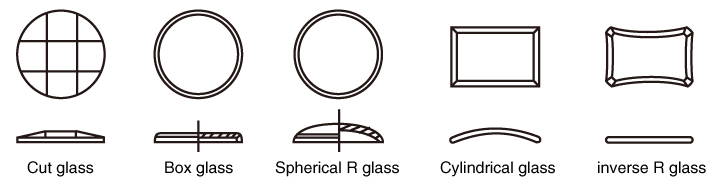

Variations of crystal glass

Since the 1970s and 80s, Orbray has had the processing technology to produce not only round, square, and irregular-shaped flat glass, as well as diamond polished cut glass, but also a wide variety of other shapes. For example, box glass, cylindrical glass, spherical R glass (dome glass), and inverse R glass could be made using the special technique of flame fusion press molding. Accuracy could be met according to customer request, from ±2/100mm to ±5/1000mm.

Orbray mainly used the following types of crystal glass, with the exception of red glass:

| K1 glass | Thinner cover glass developed using chemically-strengthened glass |

| Crown glass | Highly transparent cover glass used for optical applications |

| Potash lime glass | Highly transparent cover glass used for luxury watches |

| Soda-lime glass | Transparent cover glass commonly used for windowpanes |

| K2 glass (float glass) | Cover glass that makes the best use of a float surface (no processing) |

| Red glass | Translucent red cover glass used for digital LED displays |

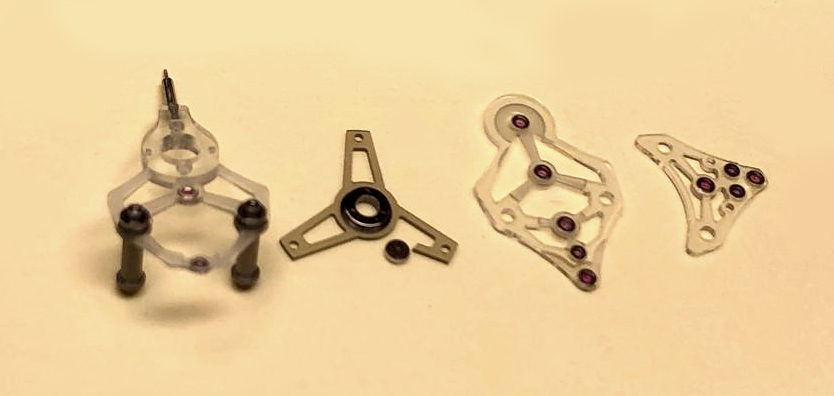

Cut glass

Using the gem processing technology of the time, the surface of the cover glass was cut on multiple sides like a jewel, resulting in a fashion watch that with the brilliance of jewelry. Compared to the simple flat shape of conventional wristwatch glass, cut glass with its three-dimensional shine became a fashion item both in Japan and abroad, and was adopted for many models of both women's and men's watches.

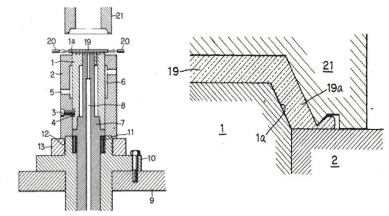

Box glass

The switch from plastic to glass as a watch cover material made it difficult to ensure enough space for the watch hands to move, due to glass's poor processability. Box glass was developed in response to this problem.

This thin cover glass was successfully co-developed with Nagoya Industrial Research Institute by bending the circumference of the glass into a box shape. That was done by heating just the part of the glass that needed to bend to about 800℃, and then pressing it by using Orbray's original mold.

We started off by making round windows, and later progressed to CRT television and elliptical shapes. This collaboration was also the start of later industry-academic-government joint development projects.

LED red glass

Advancements in digital technology in the 1970s brought about watches with novel red glass display windows.

Red filter glass was made to match the properties of red LEDs, which have a primary threshold wavelength of 645nm.

Green glass covers were also developed that were optimized for green LEDs, which have a central wavelength of 520 - 550nm.

This watch trend lasted about 3 years before shifting to the more power-efficient LCD displays seen on digital watches today.

Even today, we as a watch component manufacturer have continued launching unique watch parts.