Photoelectric fusion devices and silicon photonics

In recent years, the rapid development of information and communication technologies has led to dramatic increases in data processing speed and volume. These are expected to continue increasing in the future, bringing about related data processing challenges. Photoelectric fusion and silicon photonics technologies are attracting attention as solutions to these problems.

NTT has proposed the Innovative Optical and Wireless Network (IOWN®) concept to form the foundation of the next-generation network. One of the three elements of the IOWN® concept is the all-photonics network. Photoelectric fusion and silicon photonics technologies are key to building an all-photonics network. These technologies require high-precision processing to accurately guide light.

This article describes photoelectric fusion, silicon photonics, IOWN®, and high-precision processing technologies.

※“IOWN®” is a trademark or registered trademark of Nippon Telegraph and Telephone Corporation.

Table of contents [close]

- 1. Photoelectric fusion devices:Challenges caused by increased data processing speeds and volumes

- 2. Creating all-photonics networks with photoelectric fusion

- 3. Silicon photonics: Electronic and optical circuits on a single silicon substrate

- 4. Delivering optical signals to high-density integration silicon photonics devices

- 5. The essential role of high-precision processing technology in next-generation information networks

Photoelectric fusion devices:Challenges caused by increased data processing speeds and volumes

Recent advances in digital technology have dramatically transformed social activities. Remote work, said to take over a decade to become mainstream, has quickly become commonplace. The capabilities of auto-generated AI have taken large leaps, making faster and more human-like responses possible. Many companies are also overhauling their operations using various cloud services.

As the amount of data being processed steadily rises. Consequently, the demand for data centers and network systems, which form the backbone of these advancements, is increasing yearly. As data volume grows, the need for faster processing and seamless transmission become even more critical. However, this leads to significant increases in power consumption.

Data centers house numerous servers and network devices, all of which consume large amounts of power. Cooling equipment and large-capacity power sources are required since high-speed processing not only requires more power but also generates more heat. Today, data centers account for a few percent of the total global power consumption. As data processing demands continue to rise, further increases in power consumption are expected. In an era where energy conservation and decarbonization are important topics, finding ways to reduce power consumption while meeting the growing demand for data processing is an urgent challenge in our ever-developing digital society.

One significant challenge is that faster operation of electronic components, such as CPUs, GPUs, memory, and transmission circuits, causes increased heat generation. This makes it difficult to enhance processing power while simultaneously reducing power consumption. Photoelectric fusion and silicon photonics technologies are being researched to address these challenges.

Creating all-photonics networks with photoelectric fusion

To meet these challenges, NTT has proposed the Innovative Optical and Wireless Network (IOWN®) concept. The objective of IOWN® is to build a network that offers high capacity, low latency, and low power consumption by transitioning from conventional electronics to photonics technology. The IOWN® concept consists of three main components:

All-Photonics Network: This introduces photonics-based technology to every part of the network.

Cognitive Foundation: This component connects all ICT resources, allowing for flexible control.

Digital Twin Computing: This expands the traditional concept of digital twins, replicating the interactions between things and people in cyberspace.

Photoelectric fusion technology is an essential part of creating an all-photonics network. This technology combines electronic circuits, which handle electrical signals, with photonic circuits, which handle optical signals. This fusion enables high-speed processing with low power consumption because optical signals are faster, experience less loss, and use less energy than electrical signals.

To implement photoelectric fusion technology, devices that previously processed electrical signals need to be upgraded to handle optical signals. Additionally, there must be devices capable of quickly converting between electrical and optical signals. Unlike electrical signals, which can be transmitted through simple contact, optical signals require precise positioning and guidance to the conversion device.

This transition requires new technologies and precision handling of optical signals to fully capture the benefits of the speed and efficiency of photonics devices. By integrating these advanced technologies, the IOWN® concept seeks to create a more efficient, powerful, and flexible network infrastructure.

Silicon photonics: Electronic and optical circuits on a single silicon substrate

Silicon photonics technology is essential for creating an all-photonics network. This technology combines optical circuits, using photonic devices such as optical waveguides, optical switches, and photoreceivers, with electronic circuits on a single silicon substrate.

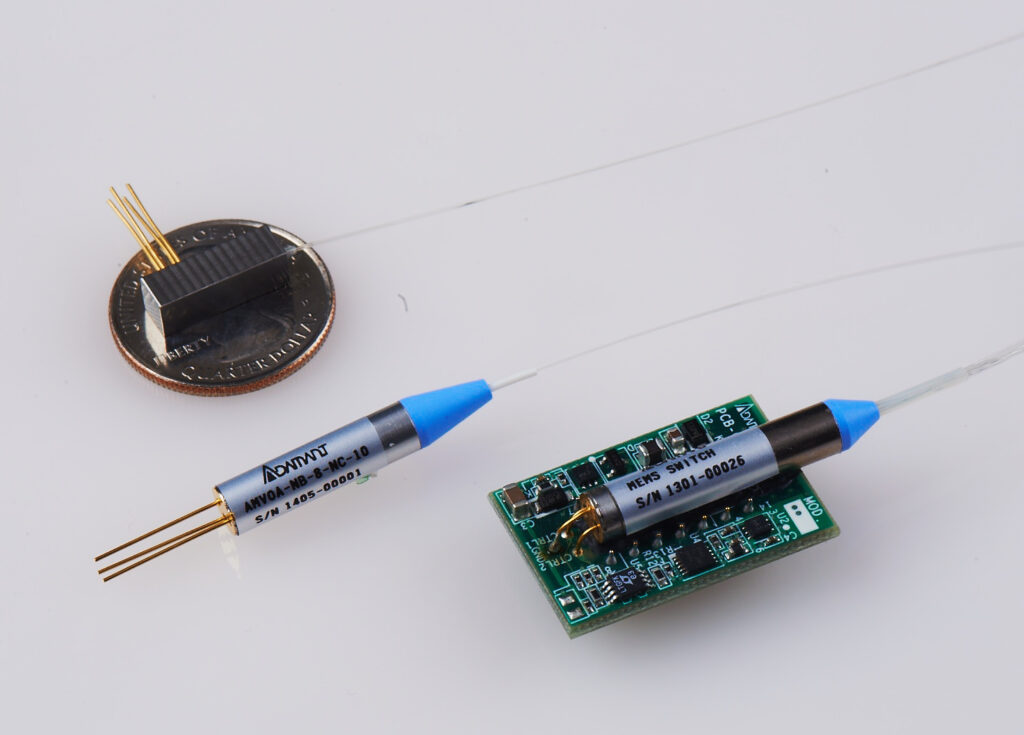

Optical circuits enable high-speed, large-capacity data transmission. With the increasing volume of data, there have been efforts to improve processing capacity and reduce power consumption by introducing high-speed, large-capacity optical circuits into electronic circuits. However, such units made by placing individual photonic devices on a circuit board require power for each device and are made of different materials, making it difficult to miniaturize and reduce power consumption.

In silicon photonics, the optical and electronic circuits are integrated on a single silicon substrate using semiconductor device manufacturing technology. This integration allows for the creation of high-speed, large-capacity, low-power communication devices that leverage the high-speed, low-loss, and low-energy consumption characteristics of optical signals. Additionally, since it can be manufactured using conventional semiconductor device manufacturing technology, it is possible to produce smaller devices at relatively low cost.

Silicon photonics technology is a key component of an all-photonics network, which aims to achieve high capacity, low latency, and low power consumption. In the future, this technology is expected to be applied to fields beyond communications.

Delivering optical signals to high-density integration silicon photonics devices

Silicon photonics technology is essential for creating an all-photonics network. But high-precision processing technology to accurately guide light to the devices is needed.

Optical signals sent from other devices must be directed into circuits and devices that handle optical signals. If the optical unit is large, it can be connected and guided with a conventional optical connector. However, it is difficult to guide optical signals using an optical connector to devices that have been miniaturized with silicon photonics technology. The positions of the photodetector that receives the optical signal and the optical fiber that transmits it, or the positions of the optical fibers themselves, must be very precisely aligned to ensure low-loss transmission.

To accurately guide optical signals to devices, various connection devices manufactured with high-precision processing technology are required. The following are examples of such connection devices.

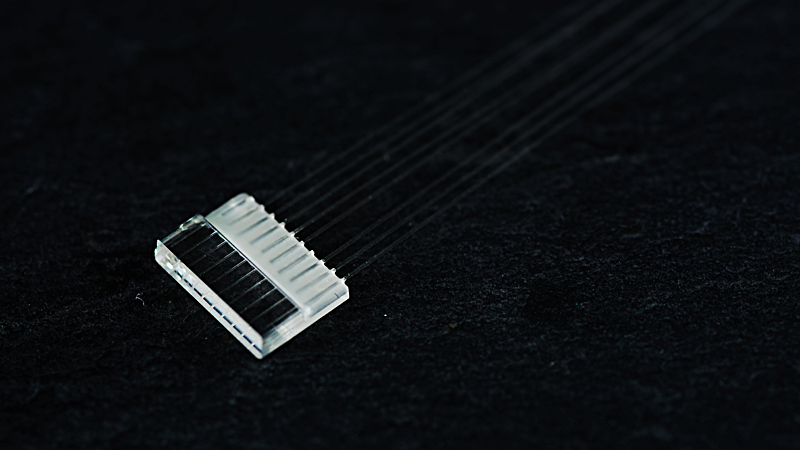

・Narrow-pitch Fiber Array

Narrow-pitch fiber arrays are connection devices manufactured using fiber etching technology and V-groove substrate processing technology. Optical fibers are inserted and fixed in a narrow-pitch V-groove substrate or micro hole array, and the end faces are polished to a submicron order level of flatness. They are used for inputting signals from multiple optical fibers to an optical waveguide element, or for splitting signals from an optical waveguide element to multiple optical fibers.

・Bent Fiber Array

The bent fiber array technology is an innovative method of bending optical fibers with the heat being discharged from the device and incorporating them into an array. By using a bent fiber array to connect with a diffraction grating-type silicon photonics device, the optical device can be made smaller.

・Glass Capillary

Glass capillaries are essential for connecting with silicon photonics devices. Compared to other materials, they offer excellent processability and flexibility, yielding good results in the PC connection characteristics of optical connectors. Another feature of glass material is its high UV light transmittance, which allows for high-speed fixing of optical fibers, lenses, and other components using ultraviolet-curing adhesives.

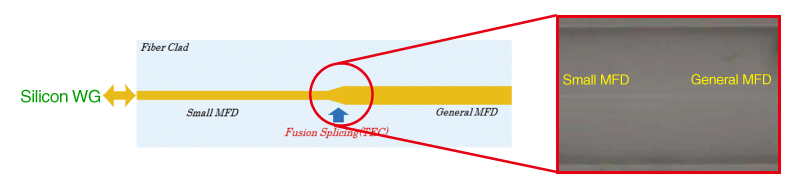

・TEC Fusion Technology

TEC (Thermal Expanded Core) fusion technology uses heat discharged from a fusion device to connect optical fibers. It is used in the manufacture of optical I/O devices for connecting different diameter MDFs between the waveguides of optical circuits (PLC, silicon photonics, etc.) and normal fibers. TEC fusion can fuse various fibers with different NAs, cladding diameters, and core diameters.

The essential role of high-precision processing technology in next-generation information networks

The development of digital technology has greatly changed our lives. The next-generation all-photonics network will further enable technologies never experienced before. However, many challenges must be overcome to make this a reality.

High-precision processing technology is essential for photoelectric fusion and silicon photonics, which are key to realizing the next-generation information networks. As advancements are made in speed, capacity, reduced power consumption, and miniaturization, the demands on high-precision processing technologies will also increase. Continuous development and evolution in this field are crucial to reaching even greater technological heights.

-

Optical Fiber Current Sensors

-

Optical attenuators and terminators: How they work and why they are important

-

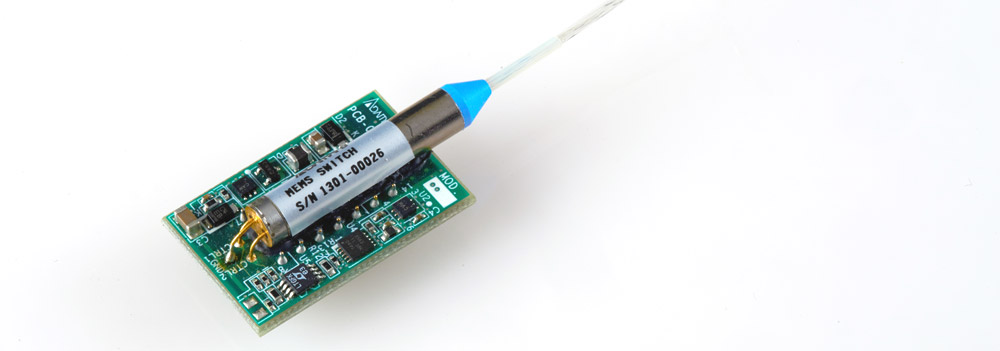

MEMS technology: Backbone of smartphone and optical communications technology

-

What is an Optical Fiber Array? - Connecting devices with optical waveguide elements are indispensable for next-generation high-speed, large-capacity optical communications.

-

What is a Ferrule? : The history and development of the ferrule continues today with its ever pursuit of high accuracy of 1um or less at reduced costs

-

Optical Switches and their significance in High-speed, Large-Capacity Optical Communications