Multi-Core Fiber:The highly anticipated, next-generation high-speed communication technology

The internet has become an integral part of modern society. 5G services, which enable high-speed, large-capacity communications, are spreading rapidly. The volume of data transmitted is expected to increase exponentially in the coming years, leading to ever-increasing demand for higher-speed, larger-capacity communications networks.

However, existing fiber optics communications networks are nearing their transmission capacities. It is in this context that multi-core optical fiber is attracting attention as an emerging technology.

Table of contents [close]

Fiber optics networks nearing their limits

The main transmission lines of optical fiber communications networks are facing escalating volumes of data traffic. Single-mode fiber is typically used in main optical transmission lines. A single wavelength of light travels through a core with a diameter of 10 μm contained in a cladding with a diameter of 125 μm. Because there are no other wavelengths of light, there is no interference or overlapping of the data signals, and the transmission loss is kept low. This makes single-mode fiber ideal for high-speed, long-distance transmission of large amounts of data.

However, there are concerns that single-mode fiber will not be able to keep up with the ever-increasing volumes of data traffic. To resolve this issue, technologies to increase transmission capacity by multiplexing have been developed. Time Division Multiplexing (TDM) is a multiplexing technology that simultaneously transmits multiple signals on a single transmission line by switching the signals being transmitted at short intervals. Wavelength Division Multiplexing (WDM) is a multiplexing technology that transmits several different wavelengths of light through a single transmission line at the same time.

In multiplexing technology, the power of the incident light must increase as the number of multiplexed signals increases. However, at a certain point, the incident light will become too intense for the fiber to withstand. Non-linear degradation of the signals is also an issue. Therefore, even if these technologies are used, the maximum transmission capacity of single-mode fiber is about 100 Tbit/s.

If the transmission capacity of a single line cannot be increased, the number of optical fibers must be increased. However, there is also a limit to the number of optical fibers that can be accommodated without increasing the outer diameter of the cable. Eventually, this method too will reach its data capacity limit.

Increasing transmission capacity with Multi-Core Fiber

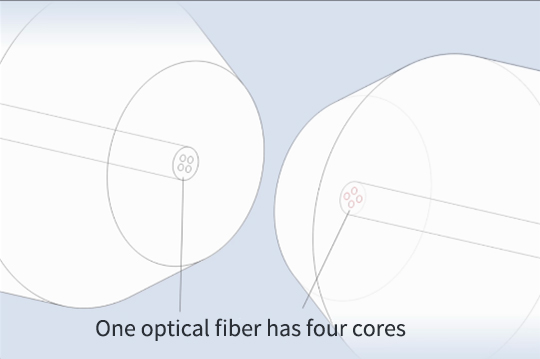

Multi-Core Fiber (MCF) solves this problem. MCF has multiple cores within a single cladding. By sending different optical signals through each core, it is possible to significantly increase the transmission capacity of a single optical fiber. This high-capacity technology using multiple cores is also referred to as Space Division Multiplexing (SDM). It makes better use of the space within the cladding than single-mode fiber, which only has one core. There is great anticipation for its utilization in main transmission lines, in submarine cables, and in the IOWN (Innovative Optical and Wireless Network) initiative. Research and development of MCF have progressed towards practical applications of the technology.

In MCF, the number of cores in a single fiber is increased by narrowing the spacing between the cores or by increasing the diameter of the cladding. As the core spacing becomes narrower, crosstalk (signal leakage) between cores becomes more likely, degrading communication quality. Also, increasing the diameter of the cladding makes it more prone to breaking when the fiber is bent. There are high hopes for the development of MCF that can be handled in the same way as current optical fiber, while minimizing signal losses.

Connectors essential for the adoption of Multi-Core Fiber

For MCF to find widespread adoption, there are challenges beyond reducing losses and increasing the ease of handling. One of these is connector technology to make the optical connections. In optical communications, optical fibers are connected to devices or other optical fibers. Therefore, connectors for MCF that are capable of reliable connections with low losses are required. Unlike electrical connections, optical signals cannot be transmitted just by making contact with the source. The cores must be in prefect alignment and contact each other without any gaps. In order to accurately connect multiple cores at the same time, the connector ferrules must be manufactured with a very high degree of precision to ensure exact alignment of the cores.

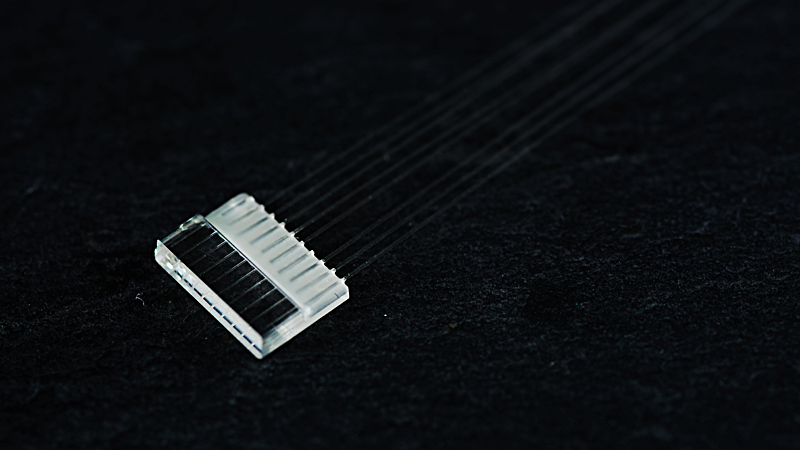

In addition, the cores of the MCF must be separated and diverted for the transmitted signals to reach their destination devices. For this, fan-in & fan-out (FIFO) technology that adapts single-mode fiber into MCF, and vice versa, is required. As with ferrules, high precision is required to bundle multiple fibers and cores with high accuracy.

At Orbray, we offer a wide range of custom-shaped special ferrules for multi-core, and many other applications. By utilizing our know-how in high-precision processing of ultra-hard materials such as ceramics and sapphire, we are able to provide complete customization throughout our product range.

-

All About Lasers: How they work, their properties, and their uses

-

Pioneering the Future of Multi-Core Optical Fiber Connections : Orbray's Optical Fiber Bundling and Light-Induced Self-Written Optical Waveguide Technology

-

Award: Industrial Standardization Enterprise Award

-

Photoelectric fusion devices and silicon photonics

-

What is an Optical Fiber Array? - Connecting devices with optical waveguide elements are indispensable for next-generation high-speed, large-capacity optical communications.

-

Optical Switches and their significance in High-speed, Large-Capacity Optical Communications