What are optical interconnects and fiber optics?

Optical interconnects are systems that connect devices such as computers and data centers to each other at high speeds using light. They are capable of transmitting large amounts of data at very high speeds. But why are they needed in the first place?

In this article, let’s explore the features of optical interconnects and the benefits of optical fiber communications.

Table of contents [close]

- 1. What are optical interconnects?

- 2. Optical fibers: An essential component of optical interconnects

- 3. Orbray’s fiber manufacturing technologies

- 3.1. Metallization and etching

- 3.2. AR(Anti-Reflection) coating and bundling

- 3.3. Bent fiber arrays and small-pitch fiber arrays

- 3.4. Collimators, focusers, and cascades

- 3.5. Glass capillaries and isolator attachments

- 3.6. Lensed fiber stubs

- 3.7. Pigtails, pipes, and TEC(Thermally diffused Expanded Core) fusion

- 4. Summary of optical interconnects

What are optical interconnects?

Let’s learn about optical interconnect technologies, why they are important, and how they are different from conventional systems. This is important because optical interconnects are expected to become indispensable for the future of the telecommunications industry.

Interconnects in data centers

An interconnect is a floor distribution panel located within a facility that is physically connected to the horizontal wiring subsystem. It helps make network connections from the cable terminal jack to the switching hub, for example. This connection method is used in many facilities due to its low installation cost and compact size.

Why optical interconnects are needed

With the growth of big data and AI, the need for large-capacity processing has increased greatly. To keep up, data centers are increasing the number of servers and using distributed processing to increase the capacity of the entire system. Conventional interconnects are approaching their processing capacities. In addition, as the distances between servers have increased, the need for optical interconnects has been growing, and research and development in the field has been progressing rapidly.

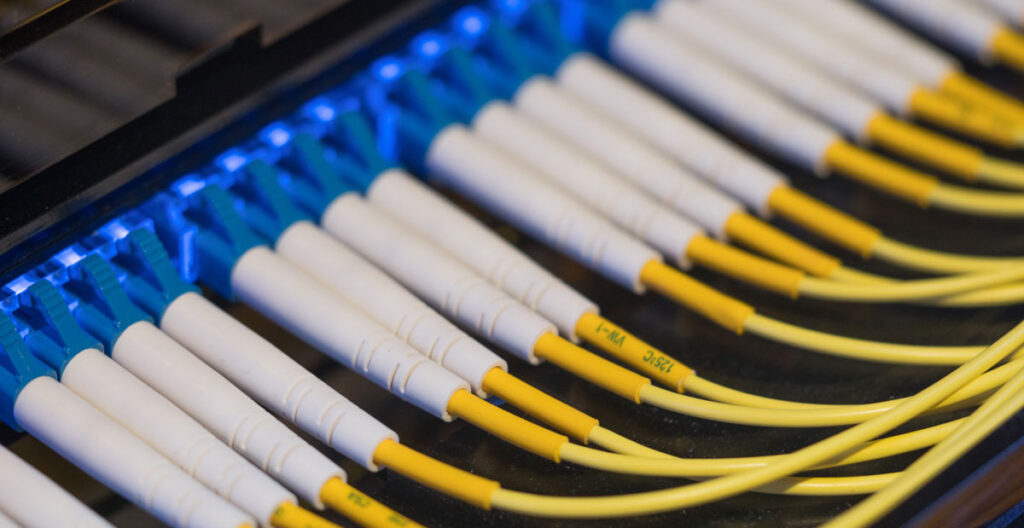

Optical interconnects make data communications connections using optical fibers. They require optical transceivers that convert high-speed electrical signals into optical signals. These transceiver have speeds of up to 25 Gbps.

Differences from conventional interconnects

Optical interconnects and fibers can achieve higher speeds, larger capacities, and longer transmission distances compared with conventional interconnect systems, which use copper wires to transmit data. Wiring can cause waveform degradation and signal interference. In addition, the number of wires needed keeps growing as more data is required to be transmitted at higher and higher speeds.

Growing demand for optical interconnects

Around the world, demand for optical interconnects is growing rapidly. The market size exceeded US$9 billion in 2020, and is expected to reach US$17.1 billion by 2025, expanding at a CAGR of 13.7%.

This growth in demand is fueled by an increasing number of data centers, developments in cloud computing, and ever increasing volumes of data being processed for big data analysis. The growth of IoT devices is also adding to the demand, as interconnects play a vital role in connecting each of these devices.

Optical fibers: An essential component of optical interconnects

This section describes the structures and features of optical fibers, which are essential for the deployment of optical interconnect technologies.

What are optical fibers?

Optical fibers are fine fibers that are capable of transmitting light. They are often made of quartz glass or plastic with high light transmittance properties. Each fiber is very thin. By bundling many fibers together, optical cables capable of carrying large amounts of data can be created.

Optical fibers and cables are mostly used for internet data communications.

Configuration of optical fiber circuits

Optical fiber circuits use light signals to transmit data. On the transmission side, an optical modulator converts electrical signals to optical signals and sends them down the optical fiber.

When the light reaches the receiver, it is converted back into electrical signals, and the data is transmitted to terminals such as smartphones or computers. This basic arrangement is behind much of the technology we encounter in everyday life, such as video streaming services and online games.

Features of optical fiber circuits

One major feature of optical fiber circuits is great cost performance. Another important feature is that optical fibers enable high-speed data transmission with very little signal loss.

High-speed data transmission

The most important advantage of optical fibers is high transmission speed. Signal transmission in ADSL, the previous data transmission standard, is limited to 50 Mbps. The maximum speed of optical fibers is 1 Gbps for both download and upload. This is 20 times faster than ADSL.

Low transmission losses

As a signal travels through the line, it can become weak due to scattering or by being absorbed by impurities in the cable materials. This is known as transmission loss. Optical fibers have very little transmission losses. This means data can be carried great distances without loss of communication speed or deterioration in image or sound quality, resulting in reliable, high-quality communications.

In comparison, ADSL has significant transmission loss issues. For ADSL, as the distance from the base station increases, losses increase, and communication becomes unstable. This is one of the drivers boosting demand for optical fiber.

Orbray’s fiber manufacturing technologies

Orbray has a wide array of fiber processing technologies. They are based on the grinding and polishing technologies we have cultivated over decades of manufacturing jewel bearings for watches and other precision products. Let’s take a look at the optical fiber processing technologies making use of Orbray’s high technical expertise.

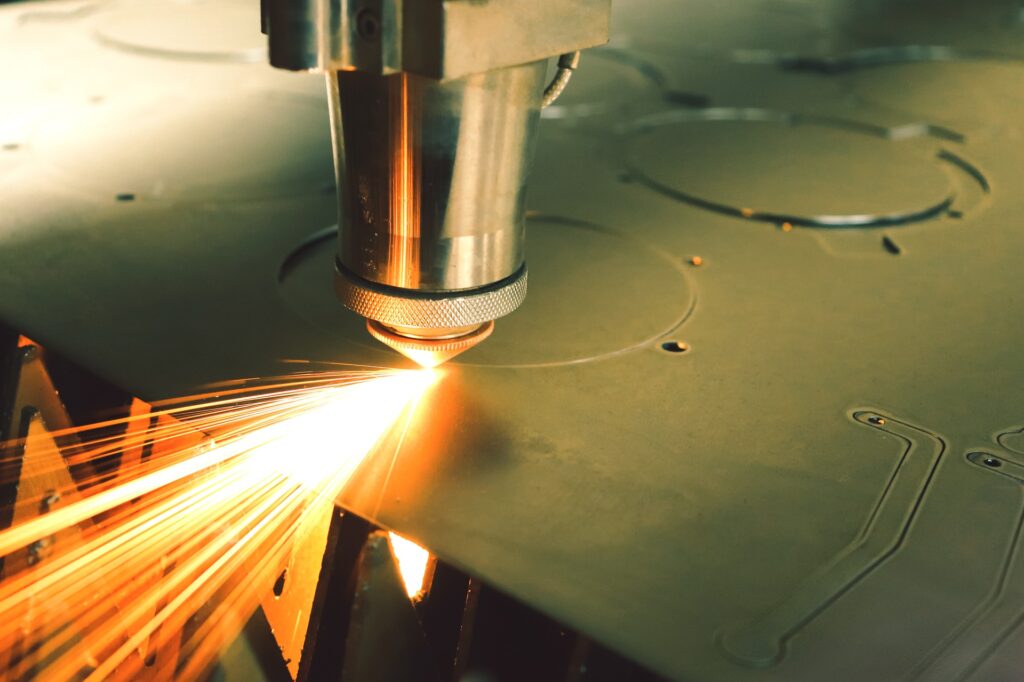

Metallization and etching

Metallization is technology essential for manufacturing butterfly optical modules and optical pump modules. Metallization is achieved when fibers are coupled with the LD(Laser Diode) inside the optical module and fixed by soldering the optical fibers.

Etching is also an effective technique for miniaturizing and increasing the density of optical devices. The cladding diameter can be adjusted by narrowing the pitch of the optical fiber array or using it for fiber bundle applications. This saves space in existing products.

AR(Anti-Reflection) coating and bundling

AR coating improves the performance of the incoming and outgoing light inside a fiber. Fiber bundling refers to technology that bundles multiple fibers into a single ferrule to make fast and precise connections.

This makes it possible to easily connect different fibers and bundles of fibers to different connectors as needed. In addition, when used in conjunction with etching technology, adjustment of the pitch of the fiber cores is possible. The combination of technologies allows for increased flexibility and performance of fiber optic connections.

Bent fiber arrays and small-pitch fiber arrays

Bent fiber arrays use electrical discharge heat to bend optical fibers and assemble them into an array. When used for coupling with diffraction grating-type silicon photonics (SiP), the device can be miniaturized.

The small-pitch fiber array is a fiber connection arrangement that is created by using fiber etching technology and V-groove substrate processing technology. Normally, the fiber pitch is 125 μm for SMFs (single mode optical fibers) with an outer diameter of 250 μm.

If the outer diameter is etched, a narrower pitch of 50 μm or less can be achieved.

Collimators, focusers, and cascades

Collimators and focusers are optical components that collimate and focus light, respectively, using spherical or aspherical lenses and fiber tip processing. Orbray’s unique optical design and processing techniques enable us to create beam diameters of any desired diameter.

Two-stage cascades are assemblies of rows in two or more layers on top of each other. Optical fibers are arranged and fixed with high accuracy in one horizontal row and two vertical rows on a V-groove substrate formed by high-precision processing technology. In order to reduce transmission loss, high precision of sub-micron order is required.

Glass capillaries and isolator attachments

Glass capillaries are essential components in the manufacture of digital coherent optical devices and connections with silicone photonics. A variety of shapes can be made, such as 2-core ferrule types, and D-cut types. Borosilicate glass is the standard material for glass capillaries.

Optical isolators are placed near the LD. Isolators are one-way optical components that transmit light emitted from the LD while blocking light coming from the opposite direction. Soldered types using metallization or YAG welding, adhesive types, cylindrical types, surface mounting types, receptacle types, and others are available to meet any specific requirements.

Lensed fiber stubs

Optical devices with lenses are made by incorporating spherical or aspherical lenses into metal parts in the design of the optical devices and optical modules. The fibers are press-fitted into the metal parts and sealed with glass that has a low melting point, and a specified AR coating is applied to the surface.

Fiber stubs are internal components that connect receptacle-type optical modules such as TOSA(Transmitter Optical SubAssembly) and ROSA(Receiver Optical SubAssembly). They are mounted inside the receptacle using press-fit techniques and provide stable connections with the optical connector.

Pigtails, pipes, and TEC(Thermally diffused Expanded Core) fusion

Pigtail fibers are used to make coaxial optical modules, butterfly optical modules, and other optical devices. One side is made by adhesion and oblique polishing of SUS ferrules in which zirconia capillaries are press-fitted into precision metal pipes. SC and LC optical connectors are attached to the other side.

Piped technology employs pipes for added fiber protection. TEC fusion splicing is a technology that uses a fusion splicer to connect optical fibers using discharge heat.

Summary of optical interconnects

Conventional circuits are nearing their limits and the next generation of high-capacity data transmission solutions is needed. As a result, demand for optical interconnects is growing rapidly, as optical fibers have high data transfer speeds and can efficiently transmit large amounts of data. They are being used increasingly in internet infrastructure and data centers.

In addition, since optical fibers are resistant to electromagnetic interference, high-quality communications is possible with almost no signal deterioration. This is a great advantage over conventional technology. Optical interconnects are expected to continue to develop in the future and play an important role in society, which requires high-speed, large-capacity communications.

You can find out more about Orbray's optical fiber processing technology from the links below.

-

All About Lasers: How they work, their properties, and their uses

-

100 times faster than 5G! What is possible with 6G?

-

Award: Industrial Standardization Enterprise Award

-

Silicon Photonics: Why is it essential for 5G?

-

Optical attenuators and terminators: How they work and why they are important

-

Lensed Fibers: Brief introduction to the functions and manufacturing methods