Biomaterials: Features and challenges for commercialization

Biomaterials are essential for medical devices of the future.

Orbray is hard at work developing biomaterial products to contribute to the next generation of medical devices.

For those looking to use biomaterials in new products or looking for new materials that are compatible with the human body, this article describes the features of biomaterials, some remaining challenges, and current applications.

Table of contents [close]

What are biomaterials?

Biomaterials are materials used in medicine and dentistry. They are often in used in cases where the medical (or dental) device interacts directly or indirectly with living tissue to repair damage to the body and where side effects must be avoided.

The previous generation of biomaterials are well-known in applications such as artificial joints, dentures, and dental implants. Recently, biomaterials are being used in the field of regenerative medicine.

Plastics, ceramics, and metals such as stainless steel and titanium are some common biomaterials. By utilizing our ceramic molding and processing technology cultivated over decades of experience in development of optical communications components, Orbray has developed a new biomaterial called Bio-Zirconia®, and has already started suppling products, mainly for the dentistry field.

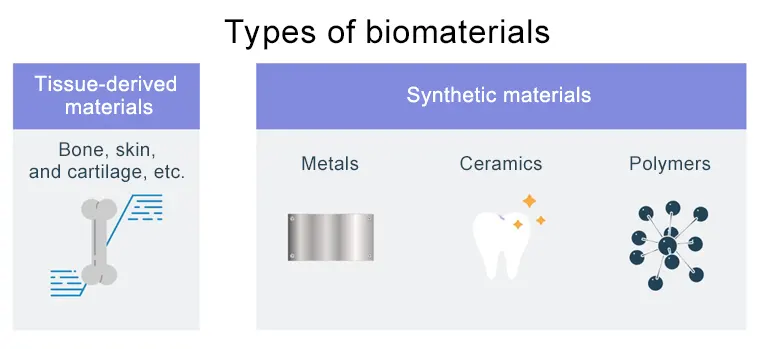

Types of biomaterials

Biomaterials can be broadly classified into tissue-derived materials and synthetic materials.

Tissue-derived materials

As the name suggests, these materials are obtained from tissues of animals, such as bone, skin, and cartilage.

Synthetic materials

Synthetics are mainly divided into three categories: metals, ceramics, and polymers.

Features of biomaterials

High biocompatibility

High biocompatibility of a product means it has no harmful effects when directly or indirectly interacting with living tissue. This is the most important requirement for biomaterial products.

The human body often rejects foreign objects that enter it, causing undesirable rejection reactions and other side effects. In addition, if the flexibility and strength of the material are different from the surrounding tissues, the material could damage surrounding tissues during intense or strenuous movements.

Biomaterials must have high biocompatibility in order to avoid these problems.

The many types of biomaterials

As mentioned above, there are several types of biomaterial products, from those made of living tissues to synthetic materials. It is important that the right materials are selected for each application when making new products.

Challenges for biomaterial products

There are three main challenges when considering biomaterial products.

Cost

Biomaterials are required to have high levels of biocompatibility in order to prevent the occurrence of side effects. This requires biomaterial products to meet very stringent requirements. As a result, they tend to be more expensive to commercialize and manufacture.

Safety

Even if safety is demonstrated in a laboratory setting, concerns of infection of the surrounding tissue and corrosion of the material when used in vivo over a long period time must be addressed. Corrosion is a major issue, especially for metallic biomaterials. Toxicity to cells and allergic reactions due to elution of ions from the material are also concerns.

Therefore, in product development, biocompatibility must be considered and materials must be selected carefully according to the application.

Mechanical strength

When biomaterial products are used in vivo, their mechanical strength becomes a critical factor due to the difficulty in removing them if broken, and the potential damage they could cause to surrounding cells.

However, when surface modification is often necessary to promote interaction with living tissue, mechanical strength may decrease, which is a challenge that needs to be addressed.

Application fields of biomaterial products

Many biomaterial products are used in the medical field, such as in artificial bones and intraocular lenses; and in dentistry, such as in dental implants.

In addition, in recent years biomaterials have found commercial use in the medical equipment field, such as in devices for diagnosis and evaluation of diseases, and in drug delivery systems.

Furthermore, applications for biomaterials are ever expanding in the field of regenerative medicine, where development is actively underway.

The future of biomaterials

The market for biomaterials is expected to expand for a couple of reasons.

Addressing concerns of an aging population

According to the 2021 census, 28.4% of the Japanese population is over 65 years of age. This percentage is expected to continue to increase in the future.

The demand for biomaterials is expected to increase as more people start experiencing injuries and illnesses related to weaking of the body due to age. It is conceivable that biomaterials will become one factor for extending the healthy life expectancy in a super-aged society.

Long-term confidence

Data from long-term use of biomaterials in people have started to accumulate. They show that biomaterials are safe and effective over the long term, and confidence in their long-term use is increasing. This is expected to lead to an increase in the number of manufacturers adopting biomaterials in their products and expansion of the biomaterials market.

Conclusion

Biomaterial products have the potential to help improve people’s lives.

Orbray has developed a ceramic biomaterial called Bio-Zirconia® that demonstrates bioactivity.

If you are interested in this exciting field of biomaterials and want to find out more, please feel free to contact us.

-

Introduction to suction nozzles and collets

-

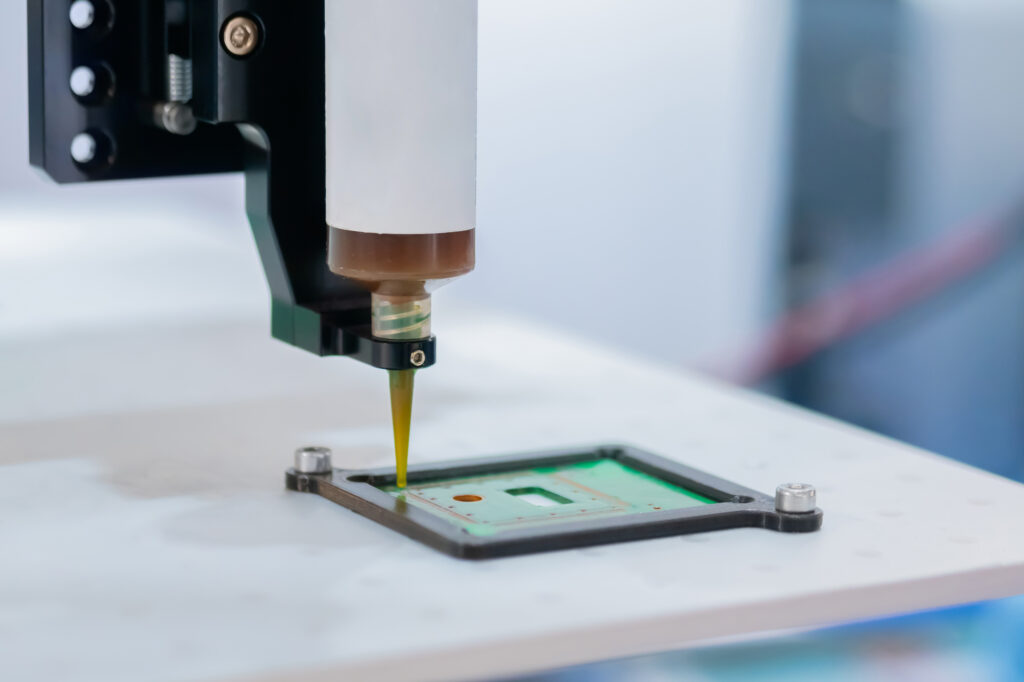

Dispenser Nozzles: Applications for dispensing liquids and selecting the right one

-

Ultra-Polishing of Sapphire along the c-Plane

-

Introducing Bioceramics: Challenges, features, and applications

-

What is a Ferrule? : The history and development of the ferrule continues today with its ever pursuit of high accuracy of 1um or less at reduced costs

-

All About Lasers: How they work, their properties, and their uses