Inner diameter measurement

Inner diameter (ID) measurement is the verification of the internal dimensions of cylinders and mechanical components.

Internal diameter directly impacts the proper fit and performance of critical parts, such as shafts and sliding parts, as well as flow properties. Therefore, high-precision diameter measurements are vital for quality assurance in manufacturing processes. To ensure accurate measurements, the appropriate measuring method and tool must be selected based on the component being measured and its characteristics.

In practice, however, it is not uncommon to see the wrong tools being used or inspections completed with insufficient precision. This can lead to unforeseen defects and degraded system performance.

This article categorizes the common types of internal diameter measurement tools, outlining their characteristics, advantages, and disadvantages, and describing how to select the right tool for the application.

Table of contents [close]

The importance of selecting the right measurement tool

While ID measurement may seem simple at a glance, it is deceptively difficult to execute correctly with high precision.

For precision instruments or automotive parts, where micron-scale errors affect performance, using equipment that does not meet strict requirements can lead directly to product failure. In these applications, depending on the type of ID measurement tool used, some methods only determine if a part falls within the allowable range (pass/fail) rather than providing an actual dimensional value.

Adding to the difficulty, measurement methods that require contact with the component carry the risk of damaging the surface of the part. Depending on the application, non-contact or non-destructive testing may be required. Therefore, high-quality ID measurement cannot be achieved without selecting a tool that suits the material, shape, and required precision of the target object.

Common internal diameter measurement tools and methods

The most common instruments for measuring inner diameters include:

- Pin gauges

- Bore gauges (cylinder gauges)

- Three-point internal micrometers (hole test)

- Air micrometers

- Optical measurement systems

Below is a summary of each method, along with their pros and cons.

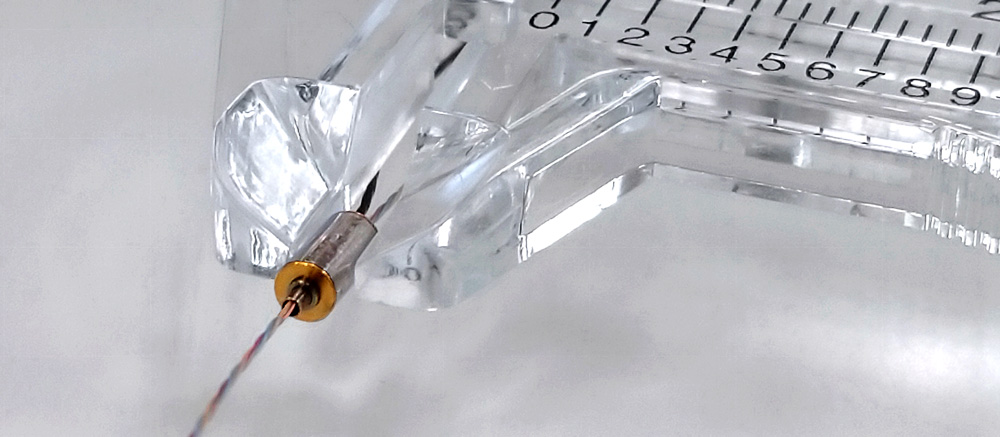

Pin gauge

A pin gauge is a simple measuring tool consisting of a cylindrical pin. It is inserted into a hole to verify dimensions based on whether the pin passes through or does not pass through. Because results can be determined relatively easily and quickly, pin gauges are widely used for pass/fail inspections on manufacturing floors.

Pros

- Are simple to use.

- Are low cost.

- Are robust and long-lasting.

Cons

- Are limited to pass/fail testing and cannot measure roundness or deformation.

- A separate gauge is required for every specific diameter.

- Cannot measure roundness or taper.

- Rust, dirt, or wear from handling can affect results.

While ideal for quick pass/fail confirmation, pin gauges are not appropriate in situations where numerical results are required. They are best used for final inspections on mass-production lines or simple in-process checks. Since they cannot provide specific diameter values, a different tool is necessary for statistical process control.

Cylinder gauge

A cylinder gauge (or bore gauge) uses a contact probe to transfer the internal dimension to a dial indicator or digital display. Its versatility allows for the measurement of deep holes, making it a standard tool for inspecting automotive and mechanical parts.

Advantages

- Allow high-precision measurement at micrometer-level accuracy.

- Are suitable for large diameters and deep holes.

- Are robust and easy to use on the shop floor.

Disadvantages

- Results can vary depending on the operator’s skill level.

- Cannot measure the very bottom of a shallow or blind hole due to probe interference.

- Contact with the surface carries the risk of scratching the part.

The bore gauge's primary strength is its ability to provide actual measured values, which can be used for process management and correction.

It is widely used for measuring precision parts like engine cylinders and for managing high-mix, low-volume production processes.

Hole test

The hole test uses three anvils that extend outwards to touch the internal surface of the hole. The three-point support system makes positioning easy and offers high reproducibility.

Advantages

- The three anvils automatically align the tool within the bore.

- A constant-force mechanism ensures consistent measurement.

- The three-point contact makes it easier to detect internal deformation.

Disadvantages

- Measurement range is limited and specific measuring heads are required for different sized holes.

- Contact with the surface carries the risk of scratching the part.

- Requires a master ring gauge for zero-setting/calibration.

Hole testers are commonly used for high-precision dimensional assurance in components such as bearing housings and mold parts. While often more expensive, they are suitable when accuracy is paramount. However, because ensuring accuracy may require multiple measurement points, they are better suited for inspecting critical components rather than 100% inspection of mass-produced items.

Air micrometers

Air micrometers are non-contact measuring instruments that use changes in air pressure to determine the inner diameter.

Because they do not damage the workpiece and provide stable results, they are frequently used on mass-production lines for automotive and mechanical parts.

Advantages

- Non-contact process eliminates the risk of damaging the surface.

- Produces high repeatability in measurement results.

- Allows high-speed or semi-automated inspection.

Disadvantages

- Entails high installation cost.

- Measurement range is limited, making it difficult to measure irregular shapes like ellipses. (While non-contact, there is still the risk of collision during insertion).

- The quality of the air supply affects accuracy.

Due to their high precision, air micrometers are a staple in the inspection of precision automotive components. However, the high initial investment can be a barrier to adoption.

Optical measurement systems

Optical measurement systems utilize microscopes, projectors, or lasers to measure inner diameters without contact. These systems excel at measuring extremely small diameters and analyzing surface conditions. They often feature image analysis capabilities for automation and multi-parameter evaluation.

Advantages

- Completely non-contact process eliminates the risk of surface damage.

- Can measure roundness and surface texture simultaneously.

- - Roundness, surface conditions, and other analyses can be performed simultaneously

- Are capable of measuring workpieces with unique or difficult shapes.

Disadvantages

- Have high installation cost.

- Degree of compatibility of the surface characteristics and laser can affect accuracy.

- ◦ Surface characteristics, oil films, water droplets, etc., affect measurements.

- Require high maintenance.

- ◦ Need a controlled environment and specialized knowledge for maintenance.

These systems are ideal for R&D or applications requiring the highest levels of quality and reliability. They are the optimal choice for workpieces that require high-precision evaluation but cannot be touched.

Unlike standard tools, optical systems can easily handle complex internal geometries.

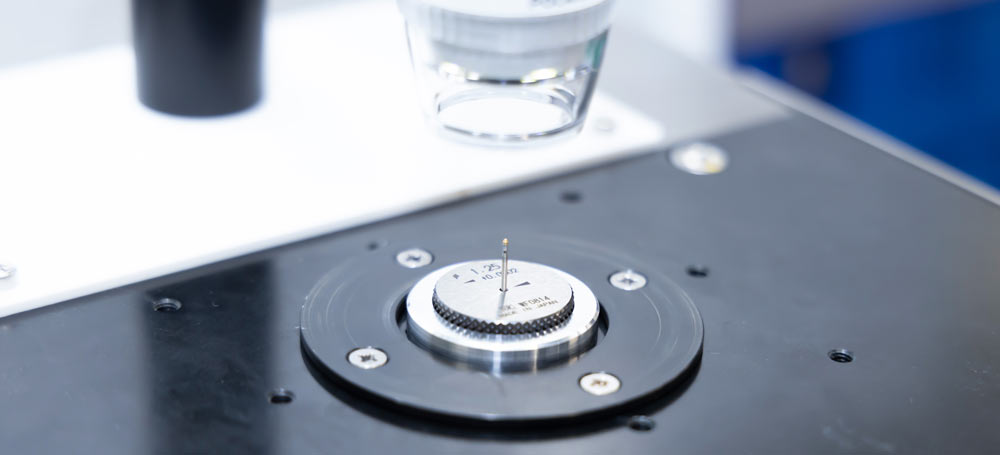

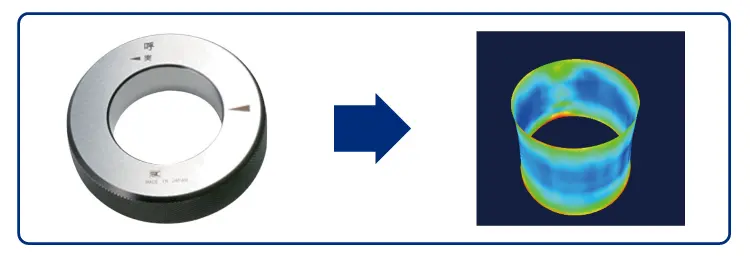

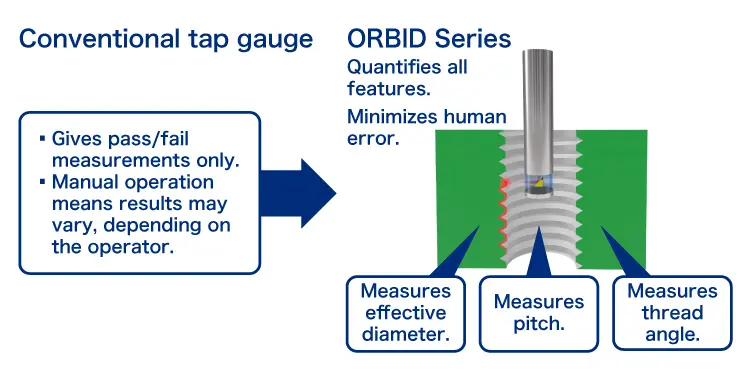

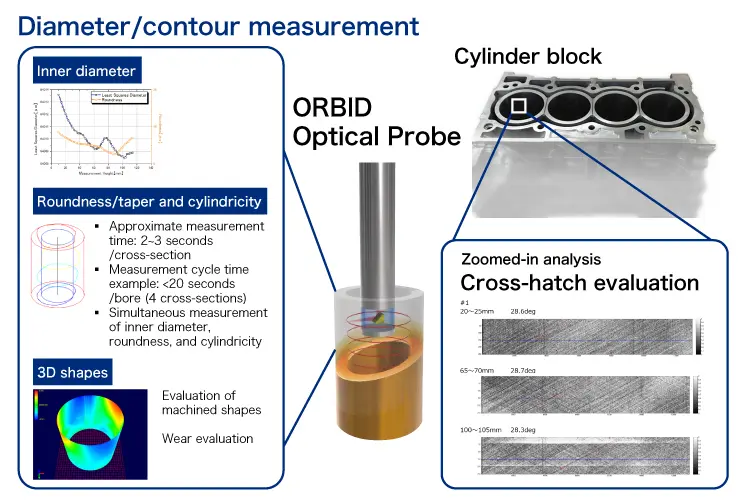

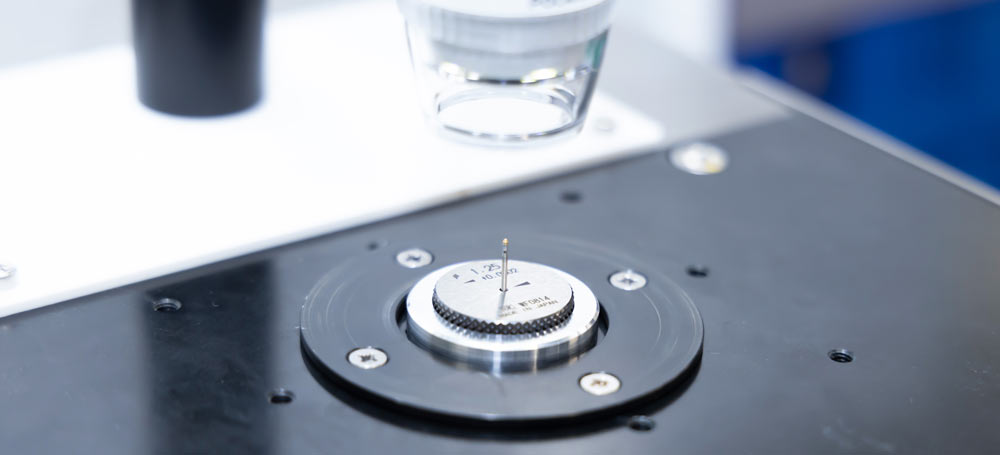

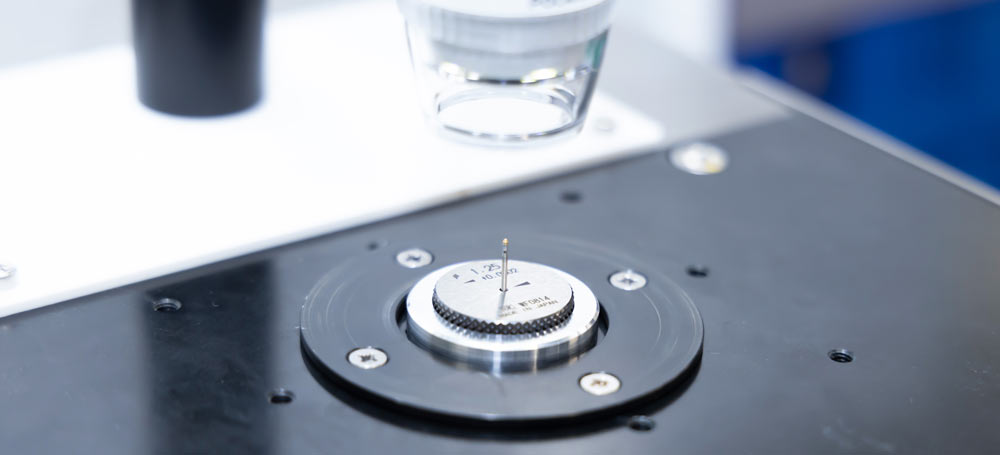

Orbray’s Optical Inner Surface Precision Measuring System

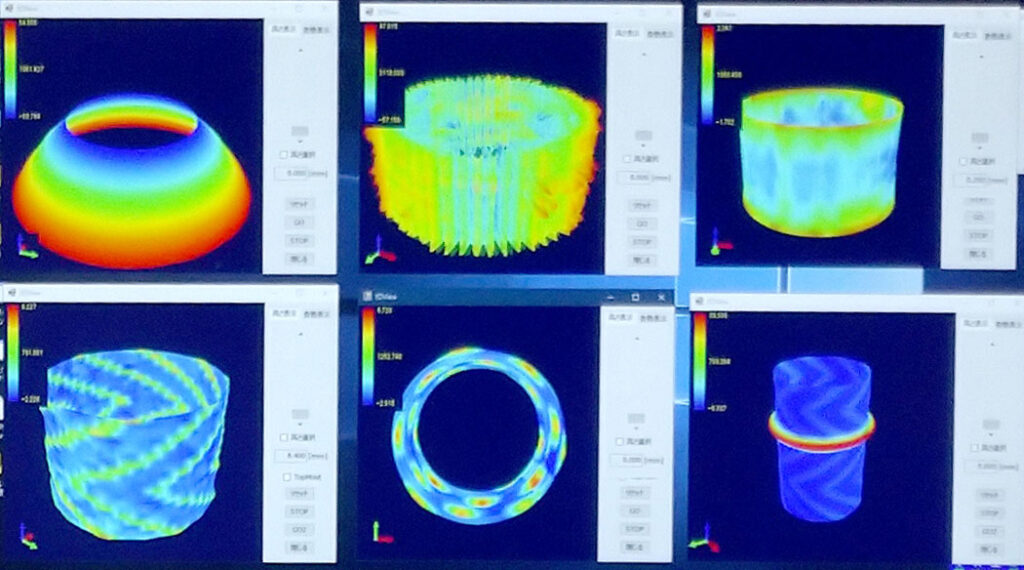

Orbray offers the Optical Inner Surface Precision Measuring System, an optical device capable of simultaneously measuring inner diameter and roundness.

Unlike conventional instruments, this system eliminates variations caused by operator skill level or material characteristics, enabling high-precision, stable ID measurement that is free from human error.

In addition to internal diameter, the system can also quantify roundness and taper, as well as measure 3D shapes. This consolidation of multiple measurement tasks can significantly reduce analysis time.

By fully exploiting these features, holes with internal diameters of 1.1 mm or more can be measured non-destructively and without making contact with the surface. Because of this, inspections can move from sampling inspections to inspection of all components, without losing valuable time to testing.

Repeatability of the system is σ= 0.02 micrometers to 0.2 micrometers, suitable for the most demanding quality-control tasks.

If you are looking to improve the quality, quantification, automation, or labor-efficiency of your inner surface evaluation, please consider Orbray’s solution.

Conclusion: The importance of finding the right tool for the job

Inner diameter measurement is an indispensable process in quality assurance, although ensuring consistent precision is a challenge.

From pin gauges that excel at rapid pass/fail checks, to bore gauges and micrometers for high-precision contact measurement, to air and optical systems for non-contact evaluation—each method has specific strengths and constraints.

The most important factor is defining the priorities of each specific task. Mass production may demand speed and stability, while precision components require micron-level accuracy or non-destructive measuring methods. Selecting the optimal measurement tool based on the target object and the objective is the key to balancing quality and efficiency on the manufacturing floor.

-

The World’s Smallest Hollow Shaft Motor

-

Visual Defect Inspection Equipment

-

What is our Optical Inner Wall Metrology System?

-

Roundness and Cylindricity Measuring Machines

-

What is a Ferrule? : The history and development of the ferrule continues today with its ever pursuit of high accuracy of 1um or less at reduced costs