Roundness and Cylindricity Measuring Machines

Splarka at English Wikipedia, Public domain, via Wikimedia Commons

Roundness is a measure of how precise a circle is in any given cross section of a hole, shaft, taper, etc.

JIS B 0621 defines roundness as the amount of deviation of a circular shape from a geometrically-correct circle.

Cylindricity is a measure of how straight and even the circle of a hole or shaft is.

Similarly, JIS defines cylindricity as the amount of deviation of a cylindrical body from a geometrically-correct cylinder.

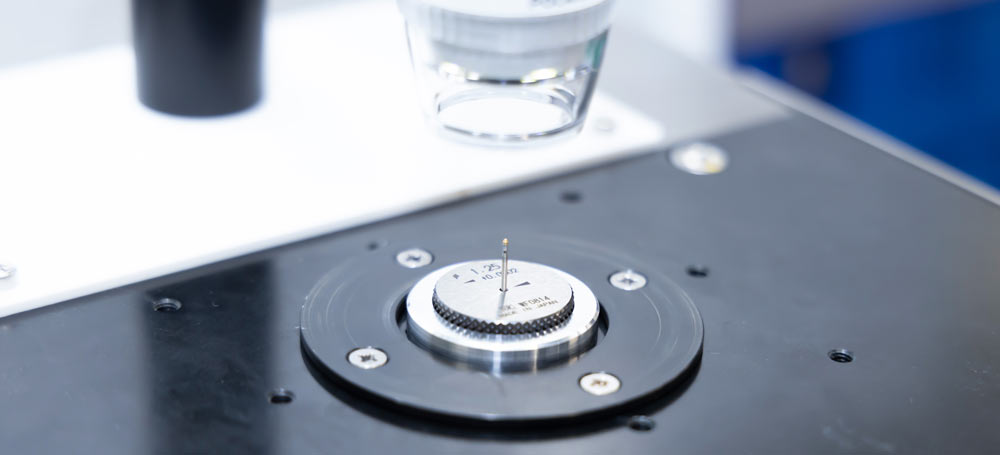

A roundness and cylindricity measuring machine is a device used to determine these measurements.

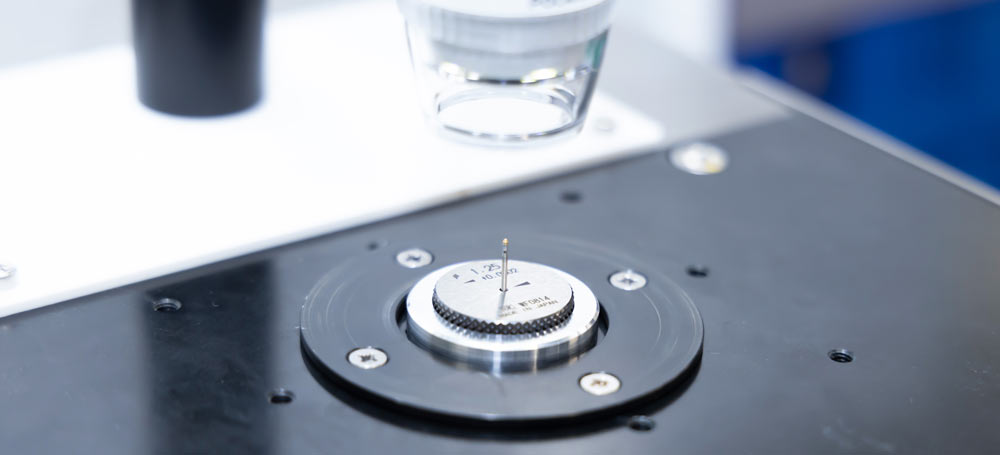

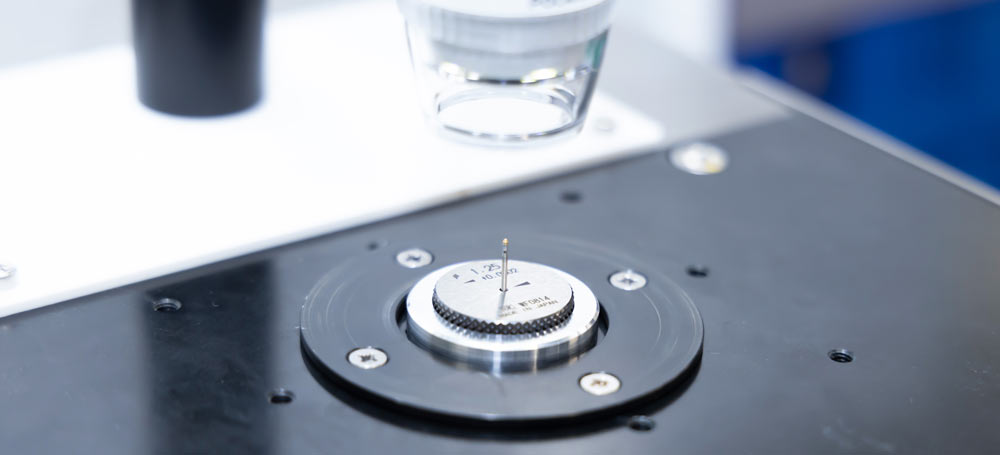

In a contact-type roundness measuring machine, the tip of the stylus (probe) of the micrometer or displacement meter is moved into position touching the object to be measured. Then either the object is rotated, or the stylus itself rotates around the object to take measurements.

The shape is obtained and roundness calculated from the measured displacement and rotational position.

Non-contact type machines include those that calculate roundness using image recognition as well as those that use optical sensors such as laser displacement meters.

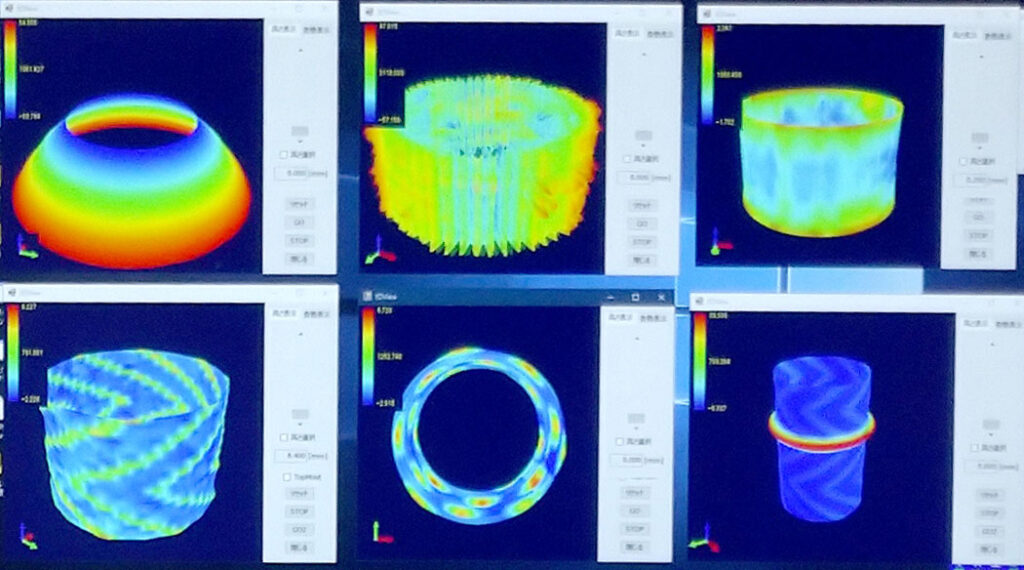

The image recognition method detects the edge of a circle from the captured image and calculates the roundness by determining the shape.

However, it is not suitable for measuring the roundness inside of a hole because it is difficult to see into anything that's deep or has a small diameter.

Machines that use optical sensors work similarly to contact-type methods, where either the object is rotated or the sensor rotates to determine the shape and calculate the roundness.

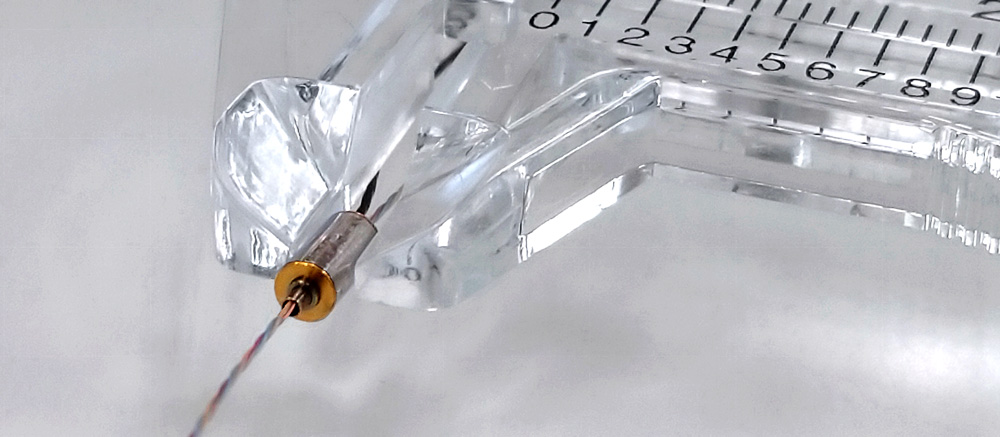

Optical sensors make it possible to take high-accuracy roundness measurements inside deep or small-diameter holes.

Orbray's optical inner wall precision measuring system negates the need for separate measurements on dedicated equipment. Our device is capable of non-contact, simultaneous measurement of inner diameter, roundness, roughness, and shape. Click here for more info.

-

The World’s Smallest Hollow Shaft Motor

-

Visual Defect Inspection Equipment

-

Inner diameter measurement

-

What is our Optical Inner Wall Metrology System?

-

What is a Ferrule? : The history and development of the ferrule continues today with its ever pursuit of high accuracy of 1um or less at reduced costs