The possibilities of Energy Harvesting: A world of self-powered devices

Table of contents [close]

- 1. Introduction

- 2. Approach to solving IoT power issues with EH

- 3. Installation procedure

- 3.1. Applications and examples

Introduction

Many devices in the modern age are IoT devices that have sensors and network connectivity. The number of such devices is expected to increase in the future. A method of powering the sensors of these devices is an issue that needs a solution for a significant number of IoT devices. For example, in large commercial parking lots, vehicles are detected using ultrasonic sensors mounted on the ceiling or by loop coils embedded in the pavement for each parking space. The installation and removal of power cords that are required to operate these sensors are major construction projects that require time and money to complete. In the livestock health monitoring field, systems that use battery powered devices are gaining popularity. However, if a large number of animals are to be monitored, changing the batteries of all the devices becomes difficult and time consuming.

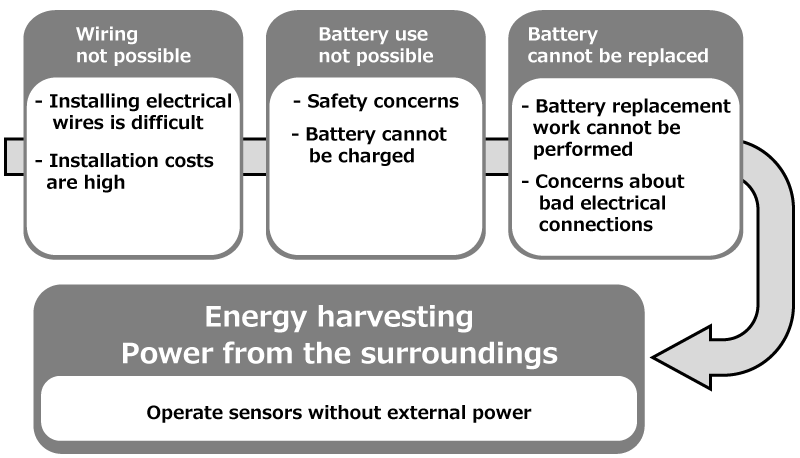

Energy Harvesting is a method of converting mechanical energy into electrical energy. It can be used to power sensors and other wireless devices without using batteries or power cords and has been gaining attention in recent years for its wide range of applications (Figure-1)

In close collaboration with partner companies and through demonstration experiments, Orbray Co. Ltd. is working to provide self-powered solutions for wireless IoT sensing devices through the development and customization of Energy Harvesting devices (“EH” hereafter).

Approach to solving IoT power issues with EH

Concept of EH devices

Many current IoT devices are fitted with wireless modules that are capable of transmitting signals several dozen meters away, such as Bluetooth Modules. However, the need for devices that can transmit signals several hundred meters or even several kilometers is expected to increase in many sectors including manufacturing, medicine, social welfare, transportation, logistics, life, entertainment, and other social sectors. Therefore, as a first concept, Orbray developed EH that can provide power to devices that are capable of long-distance communications.

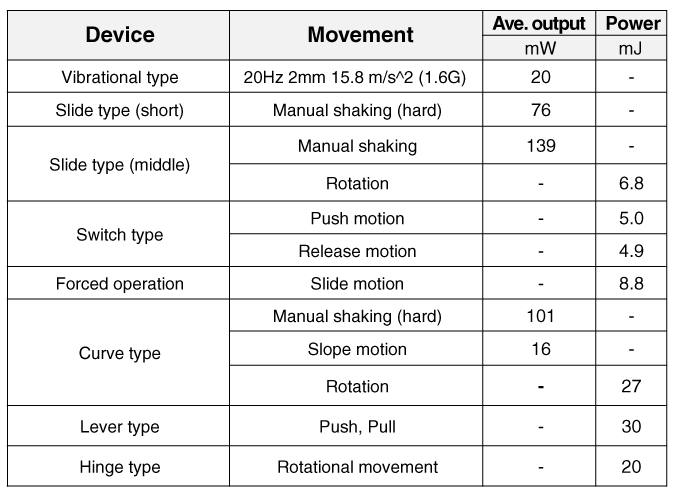

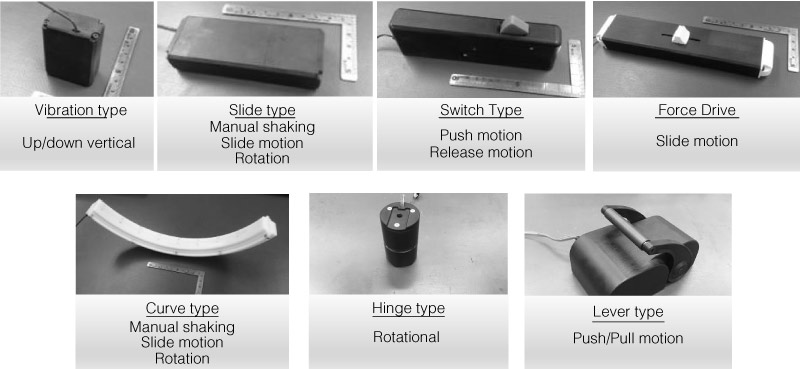

IoT functionality is expected to be applied to a wide range of devices, equipment, and everyday products soon and each is operated in unique ways. Therefore, power generation does not depend solely on up and down movements. Opening and closing of hinges, swinging motions (for wearable devices), pushing of buttons, pulling of levers, and rotating motions from wheelchairs and other devices are all sources of energy. Therefore, the second concept of development was generating power from many different types of movements.

Livestock monitoring is a growing field within IoT. However, animals such as cows and pigs vary greatly in their size and movements, and require different EH power generation specifications, sensors, wireless modules, etc. Therefore, it is desirable that not only the EH power generation method but also sensor and wireless modules can be customized for each device. This is the basis for the third development concept: development of EH devices with a wide range of customization options.

These three concepts formed the basis of development work and resulted in EH devices that generate power from a wide range of movements that are highly customizable. A very unique demo device was developed, and the product line up continues to increase and grow (Table 1, Figure 2).

What can EH be used for?

High-Output EH devices have many applications. For example, EH can provide power to landslide detection devices in prone areas, fish farm monitoring equipment out at sea, location trackers for carts in warehouses or wheelchairs in hospitals, and many other wide-ranging applications.

IoT solutions through EH

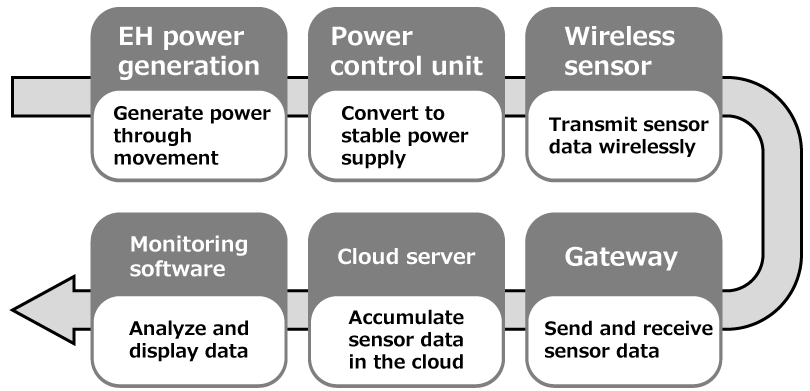

Orbray is proposing solutions that use self-powered sensing systems that utilize high-output EH for applications where securing a reliable power source is an issue. However, merely using EH rarely leads to business opportunities. Proof of concept must be thoroughly investigated. First, in addition to EH, a power control unit is needed. Unlike batteries, the output from EH is not a constant stream of power. The amount of power varies over a short period of time and sensors cannot be operated reliably. Therefore, power control units made of IC, capacitors, and other electronic components are needed to convert the energy output of the EH into a stable source of power. But even with an effective power control unit, the power generated by the EH is often limited and will not work well with sensors and transmitters that consume large amounts of energy. Particularly, the power consumption amounts written in device specifications assume stable energy supply and do not take into consideration the amount of time required to perform an operation or the total amount of power needed. Therefore, actual power consumed must be investigated by preparing many devices according to the application and measuring the amount of power consumed from the trigger to the completion of the operation. Only then can the EH, device, and transmission module be effectively integrated into a useful product.

Second, method of receiving the transmitted data must be carefully considered. Receiving data directly on a PC through a USB connection is a simple method for data collection. If data must be saved in the cloud, cloud services and IoT Gateways (“GW” hereafter) that send the collected data to the cloud through an LTE network must be prepared in advance.

Finally, if the collected data needs to be analyzed and displayed, data management software appropriate for the application will also be required.

In addition to EH, Orbray is expanding is business scope by providing effective solutions for sensors, wireless modules, GWs, cloud servers, data management software, and other elements required for a comprehensive IoT solution (Figure-3)

In summary, Orbray’s approach to commercialization of EH is to provide one-stop system solutions that possess all the technologies necessary for the IoT application and can respond to a wide range of market fields and customer requests. Cooperation with partner organizations is indispensable for such an effort, and we are also working to strengthen horizontal ties between companies, such as by participating in the Energy Harvesting Consortium.

Development of self-powered vehicle detection system

Summary

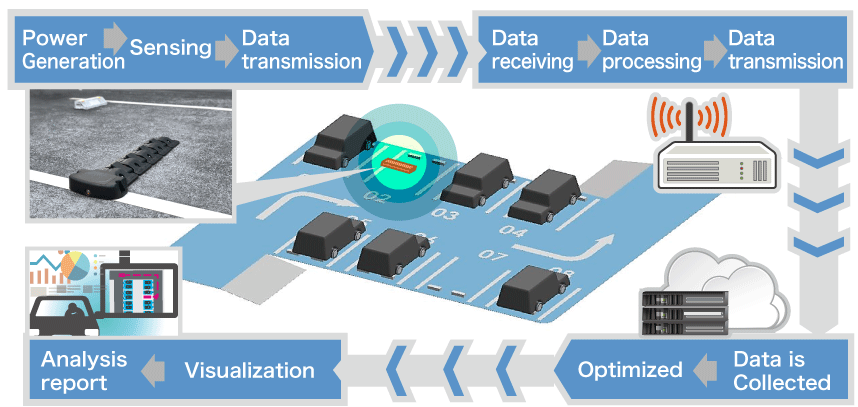

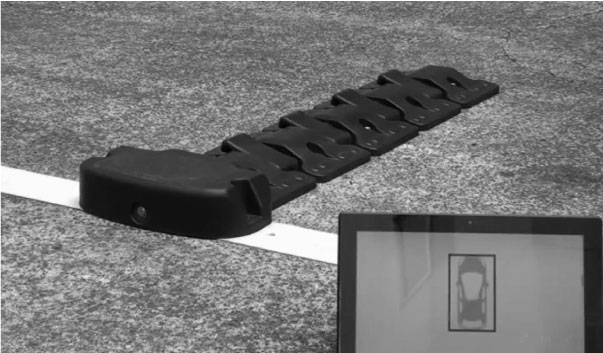

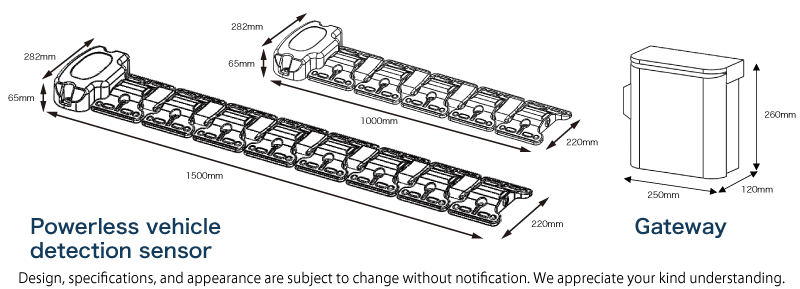

The self-powered vehicle detection system currently under development allows information such as the number of empty spaces in a parking lot or the number of available spaces to be retrieved quickly and easily. When the tire of a vehicle travels over the self-powered vehicle detection device (vehicle detector), the detector itself generates power and uses that power to transmit information regarding vehicle movement, vehicle type, and other data to the GW. The GW processes the data received from the vehicle detector and transmits it to the cloud server. The data is accumulated in the cloud server where it can be analyzed and displayed as needed. Results of operational analysis can help facility operators improve operations and improve safety and convenience for drivers and staff (Figure-4).

Major Features

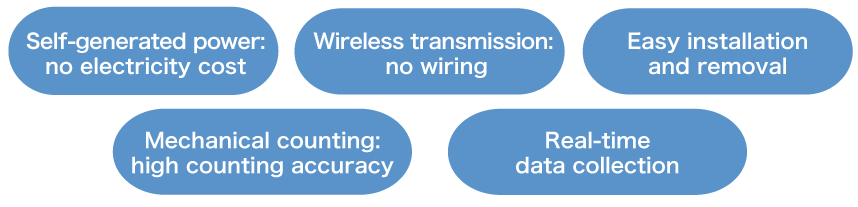

The major features of the vehicle detection system are shown in Figure-5.

Self-generated power: no electricity cost

One common method of vehicle detection is ceiling mounted ultrasonic sensors. For these systems to detect vehicles in real time, the sensors must be turned on all the time. Therefore, it is constantly consuming electricity and increases O&M cost for the parking lot. In the self-powered vehicle detection system, when the vehicle travels over the device, the weight of the tire activates an electromagnetic induction device which generates the electricity needed to operate various sensors and transmitters. Therefore, this system can deliver real time performance without external power supplies or batteries.

Wireless transmission: no wiring

Conventional systems require wires to be installed to transmit sensor data. Wiring construction can be costly and take a lot of time. The self-powered detection system uses wireless communications so installation of wiring is unnecessary, and a wireless system can be developed.

Easy installation and removal

Ceiling mounted ultrasonic detectors or loop-coils embedded in the pavement require much more construction for installation. Installation of the self-powered vehicle detection system involves anchor bolting the detector to the pavement. Removal and replacement are also very simple. This is beneficial not just for new parking lots but also for adding new spaces to existing parking lots or for rearranging the layout. Furthermore, the self-powered detection system can be useful not only in permanent parking lots but also for temporary parking lots and experimental lots used for obtaining data.

Mechanical counting: high counting accuracy

Ultrasonic and loop-coil detectors are noncontact sensors. The self-powered detector senses and counts (generates power) when the tire contacts the device. The device can detect and cancel contacts caused by people. This allows highly accurate sensing of vehicles.

Real time data collection

Apart from the ultrasonic and loop-coil sensors, there is also a battery powered magnetic sensor used in vehicle detection. In this system, there is a tradeoff between battery life and sensing frequency. Constantly powering the device can cause the battery to run out quickly. To avoid this, sensing frequency is often set to 1 time/minute. This delay in sensing can reduce real time detection capacity and may be counter to the user’s needs. The self-powered system generates power and sends data to the cloud every time a vehicle travels over the sensor. In this system, there is no time lag and vehicle conditions can be obtained instantly.

How to use

Parking space management/parking lot management

Installing a vehicle detector in each parking space will allow the operators to quickly understand which spaces are open and which are occupied. In addition, by installing vehicle detectors at the entrance/exit of the parking lot or in sections of the parking lot, details about the entire parking lot, or about certain sections of the parking lot can be obtained easily (Figure-6).

Historical data and parking lot usage forecasts

Details such as the device ID, direction of travel, detection of people, time, and other relevant data are saved on the server in real time. The accumulated data can be combined with other external data such as time, day of the week, weather, nearby events, etc. to forecast parking lot usage and number of customers to support the smooth operations of parking lots.

Optimization of operation

Real time monitoring data can be combined with historical data and parking lot usage forecasts to improve parking lot management. For example, in parking lots that use guides to direct traffic, electronic displays can be used to guide customers to parking spaces based on the real time conditions within the parking lot. This not only reduces labor costs but can provide customers with a smooth experience. In addition, with an accurate knowledge of the conditions in the parking lot, if the parking lot is full, customers can be directed to other parking lots to help reduce congestion caused by drivers waiting for open spaces. In addition, by analyzing the number of customers, prices can be reassessed. Advertisement fees can also be optimized depending on the weather, time, or nearby events.

Establishing small parking lots and temporary parking lots

The vehicle detection device can be installed by anchor bolting it to the pavement. This significantly reduces the time and capital requirements of installation. The site can quickly be returned to the original state after removal. Small-scale and temporary parking lots that were difficult to establish before can now be easily set up and removed.

Installation procedure

Real time monitoring of vehicles

For customers interested in real time vehicle monitoring or analysis of operating conditions, parking time analysis, etc., Orbray will conduct field survey and trial tests. First, the configuration of the entire system will be verified, from the installation of the vehicle detection device to confirmation of the transmission module and transmission/reception by GW will be performed. After the detection rate is verified, we will consider installation by performing pre-deployment experiments.

Parking lot conditions and analysis reports

For customers who want to know the operating condition of parking lots and distribution warehouses, and the approximate parking times, we will install vehicle detection devices at optimum locations for 1 to 3 months to gather data and send an analysis report after removal.

Applications and examples

Management of vehicles in truck bays and waiting spaces at a logistics warehouse

Application of the self-powered vehicle detector is not limited to commercial parking lots. Operational efficiency is critical in large logistics warehouses and maximizing the amount of time truck loading/unloading docks are in use is a key factor. By accurately managing bay occupancy data in real time, trucks waiting to load/unload can be contacted when needed and guide personnel can direct them to the correct place accurately. In addition, the data of each truck and driver can be collected and analyzed to improve forecasting and operational efficiencies.

Low energy parking

Ceiling mounted ultrasonic detectors and loop coil detectors embedded in the ground are common methods for vehicle detections. These systems need constant power to operate, which increases operation costs. In addition, work to mount on the ceiling and wire each device to the central computer are time and money consuming. In the case of loop coil detectors, the pavement must be dug up and resurfaced.

In contrast, Orbray’s self-powered system requires no external power sources or batteries. In addition, it communicates wirelessly with the cloud and requires only anchor bolts for installation. It can be installed quickly without large construction works and requires no external power sources.

As the number of units increase, the time and money savings also increase in the amount of reduced O&M and construction costs. The system has been used to manage parking lots for international sport events.

Simplified speed detection

When the tire of a vehicle passes over the device, the EH inside generates power which activates the sensor and transmits data to the GW. The GW attaches time stamps and other relevant details and delivers data to the cloud where it can be processed and analyzed.

When a vehicle travels completely over the sensor, both the front and rear tires will make contact and will cause the sensor to be activated twice. By recording the time difference between the two readings (and assuming a typical wheelbase length for the application), the speed of the vehicle can be estimated

Detect wrong direction of travel

The vehicle detector is fitted with a sensor that detects the direction of travel. This makes it possible to distinguish whether the vehicle entered a parking spot or left the parking spot. If the vehicle detector is installed in the aisles of the parking lot, the number of vehicles in transit can be counted. In addition, the direction sensor can detect and alert vehicles traveling in the wrong direction.

Accidents caused by traveling in the wrong direction have been increasing in recent years. Detection and prevention of such accidents has gained attention and this system can contribute to a solution.

Smooth parking with smartphone connection and parking lot signage

This system gathers information in real time and constantly updates the cloud server. This data can be integrated with existing map and parking lot applications as well as electronic displays inside parking lots to give drivers accurate and up-to-date information, thus improving efficiency. In addition, parking spot reservations can also become a possible service.

Driverless cars and valet parking

The accurate and real time information provided by this system allows constant communication between operators and drivers about the conditions within parking lot areas. This constant, accurate communication forms the basis of effective handling of driverless cars and valet parking operations.

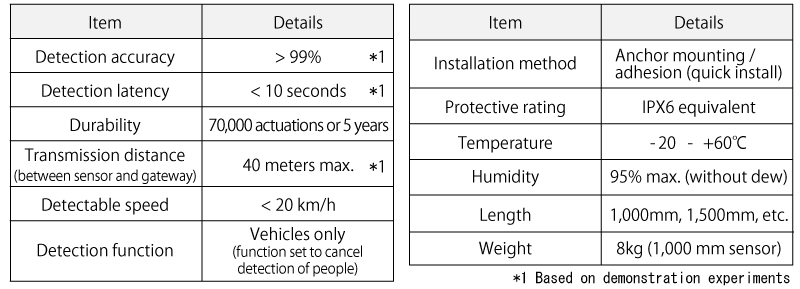

Specifications (as of 9/30/2020)

Detection accuracy: Over 99% (Based on real-world experiments in parking lots)

Detect vehicles only (cancel activations by people) feature (Table-2)

Detector width (tire contact belt width): 150mm, 400mm high (Figure-7)

Conclusion

As the IoT/M2M market continues to expand, demand for remote monitoring and management, predictive management of equipment, development of manufacturing, and visualization of industrial processes have been increasing rapidly. All these activities rely on highly accurate data collection. Orbray is working to contribute to this field and to society in general by developing self-powered and energy-saving sensors through the effective use of EH technologies.

Source: “Environmental Harvesting Handbook: 2nd Edition” NTS Co. Ltd., 2021, p249

-

100 times faster than 5G! What is possible with 6G?

-

Issues in implementing Energy harvesting devices

-

What are smart factories? The benefits of introducing IoT in factories.

-

Securing power for IoT devices

-

Transmission Distance of IoT Devices

-

Generating electricity from mechanical vibrations - How it works and what it is used for