Generating electricity from mechanical vibrations - How it works and what it is used for

Vibration powered generators are a form of energy harvesting. This process converts the vibrations and movements of machines, buildings, other objects, and even people into electrical energy.

There are four main categories of vibration powered generators: electromagnetic induction, electrostatic induction, the inverse magneto strictive effect, and the piezoelectric effect.

Table of contents [close]

- 1. Vibration powered generators using electromagnetic induction

- 2. Vibration powered generators using electrostatic induction

- 3. Vibration powered generators using the inverse magnetostrictive effect

- 4. Vibration powered generators using the piezoelectric effect

- 5. Example applications of vibrational power generation

Vibration powered generators using electromagnetic induction

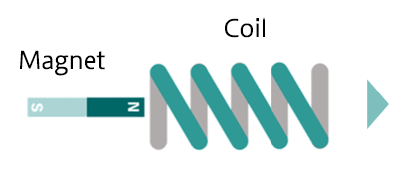

When a magnet is moved in and out of a metal coil or when a coil is spun between magnets, an electrical potential (voltage) is created. This phenomenon is known as electromagnetic induction. The voltage causes an electric current to flow, creating electric power. Power generation using a motor also uses the principle of electromagnetic induction. The magnitude of the electromotive force due to electromagnetic induction is proportional to the rate of change of magnetic flux (Faraday's law of electromagnetic induction). The current generated by electromagnetic induction flows in the direction that opposes the change in magnetic flux (Lenz's law).

The currents generated by these phenomena can be captured and used as electricity. For example, a spring and a magnet can be used to create a simple system that generates electric power. In this system, a magnet attached to a spring is placed inside a coil. When the whole system vibrates, the magnet reciprocates in the coil, causing a change in magnetic flux. This creates a potential difference, thereby generating power.

A coil with a magnet and a rotating shaft can also be used to generate power. A weight is attached to a shaft, and when the whole system is shaken up and down, or left and right, the weight moves, causing the shaft to rotate. As a result, the coil rotates and creates magnetic flux, which generates electricity. Vibration powered generators using electromagnetic induction can obtain a voltage of several volts.

Vibration powered generators using electrostatic induction

When a conductor is brought close to a charged object, electrons inside the conductor move and the opposite charge gathers on the conductor. This movement of electrons is known as electrostatic induction, and the process can be repeated to create a constant flow of electrons in the conductor, thereby generating electricity. Electrostatic induction is capable of generating tens to hundreds of volts.

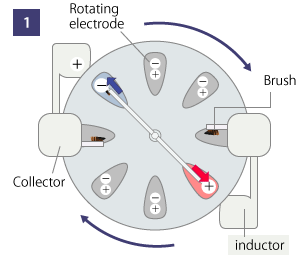

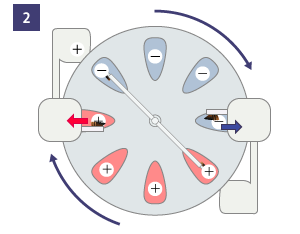

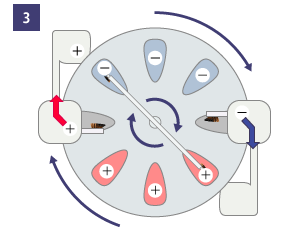

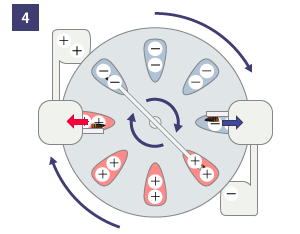

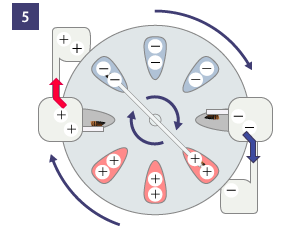

For example, rotational movement can be used for electrostatic induction. The figure below shows an insulated rotating disk with electrodes evenly spaced along the circumference. Each opposing side of the disk has a brush positioned to touch the electrodes, an inductor that induces a charge in the electrodes, and a collector that collects the respective positive or negative charge that each inductor gives.

Each opposing side of the disk has a brush positioned to touch the electrodes, and an inductor that induces a charge in the electrodes.

Rotation of the disk causes each brush to come into contact with an electrode, connecting them to one of the inductors. As further rotation separates the electrode from the brush, the brush transfers to the collector a charge of the opposite polarity of the inductor. This process is repeated, with either positive or negative charges collected by the respective collector to generate electricity.

In a further example of vibration powered generators using electrostatic induction by rotation, a weight can cause a shaft to rotate to generate electricity.

Vibration powered generators using the inverse magnetostrictive effect

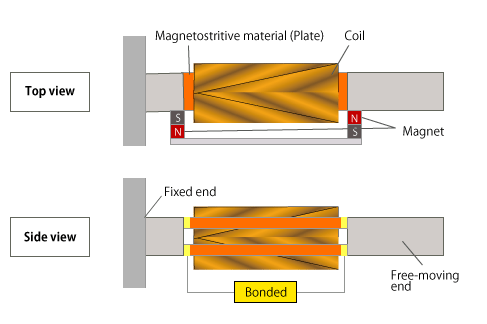

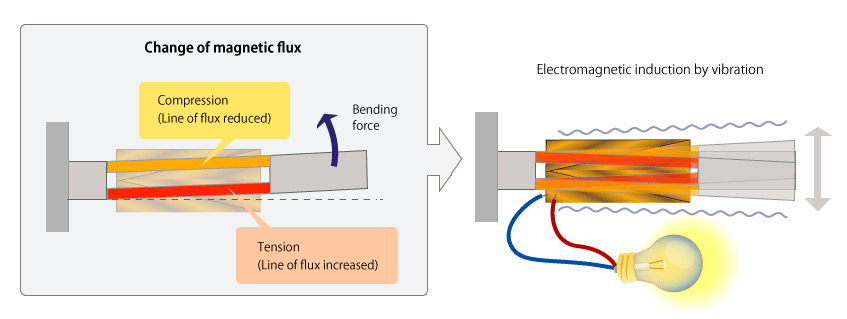

When a ferromagnetic material is magnetized, its shape can change. This is known as the magnetostrictive effect. The opposite process also occurs: if the shape of a ferromagnetic material is changed, the magnetic flux surrounding it will change. This process is known as the inverse magnetostrictive effect. This effect can also be used to generate electricity from vibrational motion.

For example, a rod- or plate-shaped metal with a high magnetostrictive effect can be positioned inside a coil made of a conductive material. When vibrational forces cause the shape of the metal inside the coil to change, the magnetic flux around the metal also changes. This change in magnetic flux causes electromagnetic induction in the coil and generates electricity. It is possible to obtain a voltage of several volts using this effect.

Vibration powered generators using the piezoelectric effect

The piezoelectric effect is a phenomenon in which electric polarization occurs when a force is applied to quartz or a specific ceramics material and voltage is generated. It is often used for igniters in cigarette lighters and gas stoves. The polarization is proportional to the force applied, and it is possible to generate a voltage of tens to hundreds of volts. In this type of power generation, a plate-shaped structure is used in which a strong force is continuously applied.

Example applications of vibrational power generation

Energy harvesting from vibrational power generation can already be seen in various practical applications. For example, floors can now generate electricity as people walk over them, and vehicle detection systems can generate electricity as a car tire passes over them. The electricity thus generated powers the internal sensor and data transmitter, so no external power or batteries are required. In addition, power can be generated by the rotation a door for open/close detectors, the movement of buoys swaying in waves, the pressing of remote control buttons, wristwatches powered by the movements of the wearer’s hand, and many other creative and diverse applications.

Devices that generate power from a wide range of movements, such as acceleration, impact, gravity, shaking, switches, rotation, etc., have also been developed.

Possible applications include remote monitoring of tunnels, bridges, waterways, and other infrastructure; keeping track of the location and condition of construction and industrial equipment; overseeing vehicle operation and positioning; livestock health management; home security; health and safety monitoring networks; disaster prevention and response; and many others.

As the number of IoT devices continues to increase, the number of and applications for energy harvesting from vibrations for IoT devices that are efficient and easy to install are also expected to grow.