The World’s Smallest Hollow Shaft Motor

In recent years, there have been significant technological advances in high-performance, compact, and lightweight precision equipment, such as industrial robot end effectors and dimensional measurement devices, and medical equipment such as functional endoscopes and catheters. Miniature hollow shaft motors have attracted much attention as an essential piece in these technologies.

Table of contents [close]

What is Hollow shaft motors?

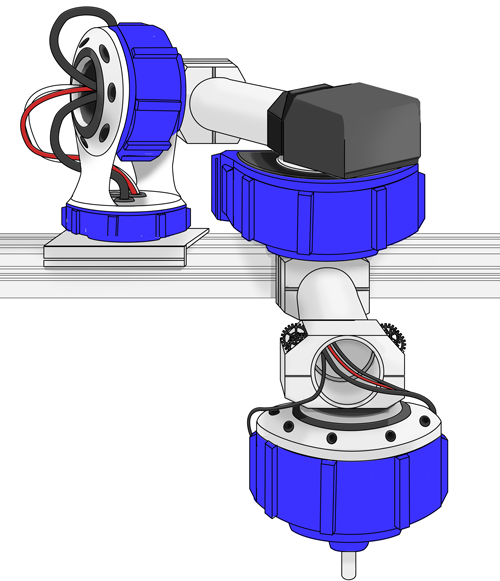

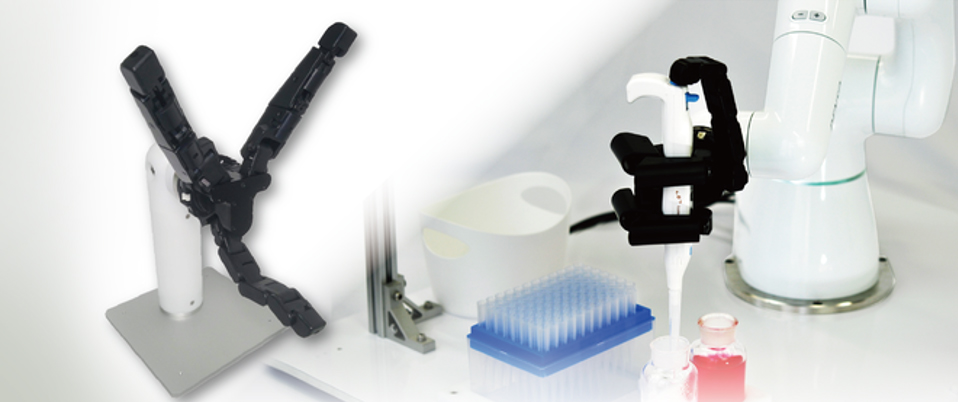

When multiple motors are used in a single device, it can be difficult to install the electrical wiring for power and control signals in the limited space available. Space can be utilized more efficiently by routing the wiring through the shaft of the motor itself. For example, robot arms and end effectors employ many micromotors to replicate human movement and dexterity. Running the required wiring through hollow shaft motors greatly contributes to miniaturization of the device.

Hollow shaft motors have a hollow structure, and come in several variations such as DC brushless, AC servo, stepping motors, etc. However, for applications requiring compact, small diameter motors, DC motors that are coreless, sensorless, and brushless are optimal.

Brushless DC motors are used in a wide range of applications, and have advantageous features such as compact size, high efficiency, high controllability, and low driving voltage.

As modern devices continue to be made smaller and lighter, the motors used in them also need to be further miniaturized. Motor parts must be made smaller and more precise than ever before. In pursuit of the “world’s smallest motor”, Orbray has developed a miniature, hollow shaft motor by fully applying our precision processing and assembly knowhow.

The world’s smallest hollow shaft motor

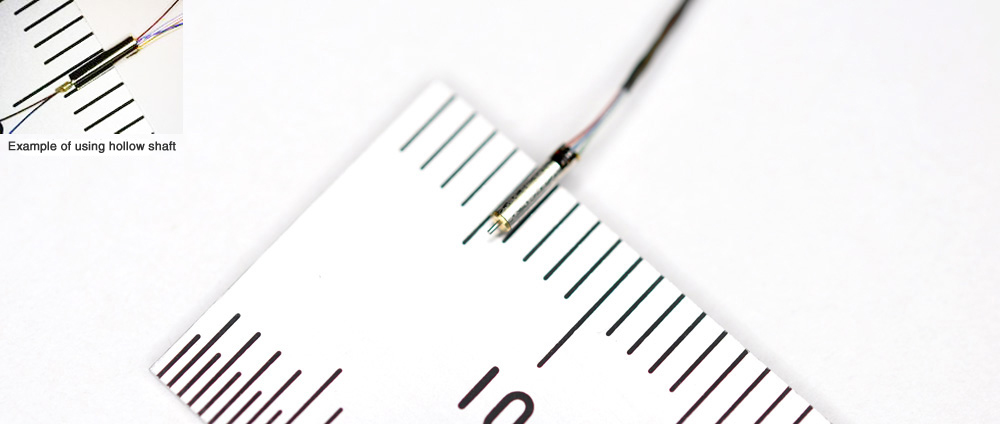

Our motor’s dimensions are φ0.9 mm, with an overall length of 3.8 mm, and the hollow shaft has an outer diameter of 0.2 mm and inner diameter of 0.18 mm.

Since the small 0.9 mm diameter makes it difficult to install Hall-effect sensors, we use a brushless, sensorless drive, giving a torque constant of 12 µNm/A.

Because the motor has a hollow shaft, wiring can be run through the motor itself, which allows for greater flexibility in device design. Alternatively, functional components such as fiber optics or guide wires can be passed through the hollow shaft, contributing to high-performance configurations in a small amount of space.

Applications for small hollow shaft motors

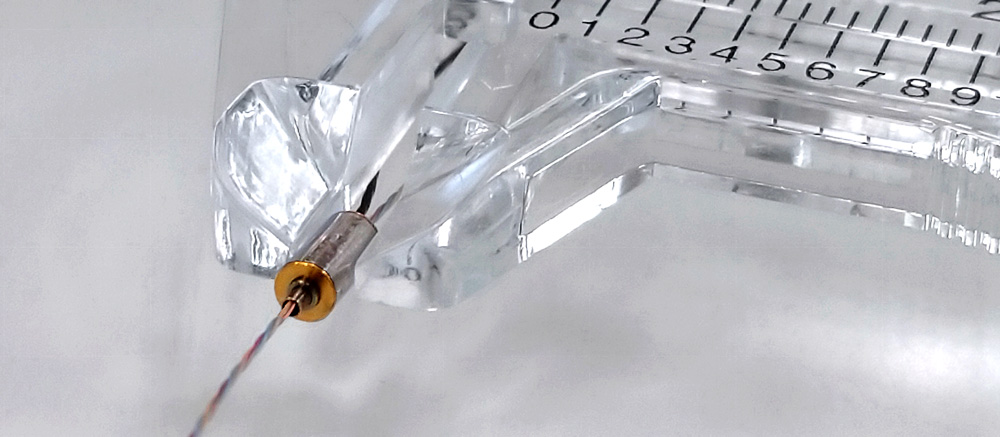

By combining the high-performance motors described above with fiber optics, Orbray has developed and released a 0.9 mm diameter optical probe that is able to take a 360° scan of its surroundings. Our Optical Inner Wall Metrology System can measure the inside of an opening as small as 1.1 mm, and makes simultaneous, non-contact analysis of inner diameter, roundness, scratches, etc., as well as visualization of the inner surface possible. This system is expected to be useful for evaluating the inner surfaces of precision hole processed parts and equipment – for example, engine bores, shaft bearings, fuel injection nozzles, hollow medical components, or precision nozzles for analysis equipment.

Optical Inner Wall Metrology System

In addition, devices that are inserted into the human body require guide wires, which makes a hollow shaft configuration in the motor essential. Multiple manufacturers and research institutes in Japan and the United States are conducting research into mounting such devices onto functional endoscopes and catheters.

-

Robotic Hands

-

Small Motors (Mini Motors): Applications and Required Technology

-

The Story of Motor - Rule, principle and history -

-

What is a Ferrule? : The history and development of the ferrule continues today with its ever pursuit of high accuracy of 1um or less at reduced costs

-

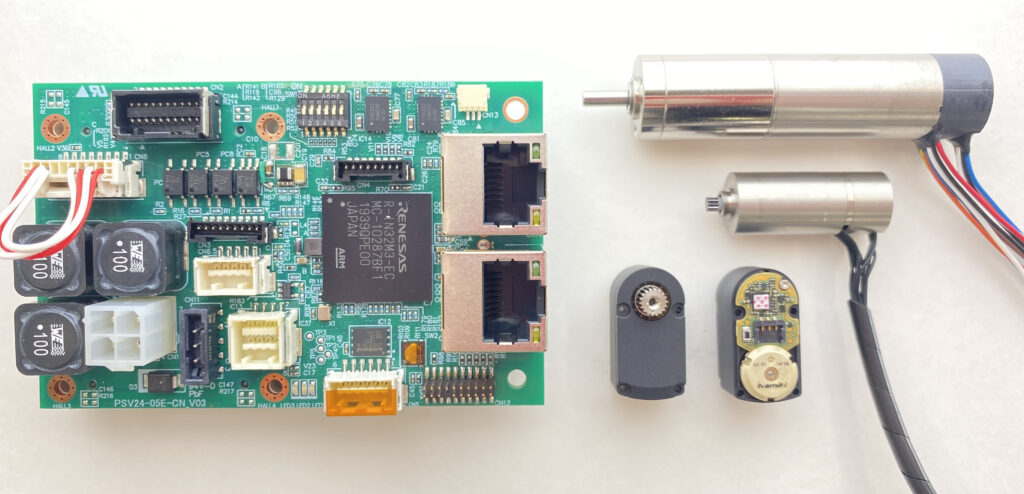

Servo-drivers: How they are made and how they are used

-

Brushless motor vs brushed motor: The features of the Orbray brushless motor.