Sapphire Glass [Story of Watch 4]

Table of contents [close]

Sapphire glass material and processing

As Japan's economy boomed, luxury watches began to garner more attention.

Sapphire was an ideal material for these watches since it is a hard material and scratch-resistant. However, due to its hard structure, machining was very difficult.

We developed our own tools and a new polishing method for optimal processing. The watches became such a huge hit that sometimes production could not keep up with demand.

Later, as demand for product variety rose, we also applied designs in colors such as metallic gold, silver, and blue to the outer frame of the glass cover using vapor deposition technology and photo-etching.

Recently, recognizing Orbray's past achievements in sapphire processing technology, a Swiss manufacturer of ultra-luxury brand watches placed an order for a limited-edition, specially-shaped sapphire window, which has been introduced to the world as part of a rare and beautifully-designed model of watch.

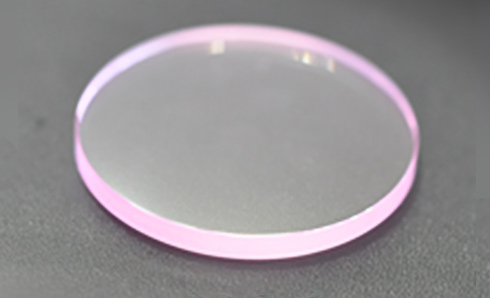

Additionally, in 2020, Orbray successfully developed a pink sapphire glass using our proprietary EFG growth method, and has presented samples for use as watch glass.

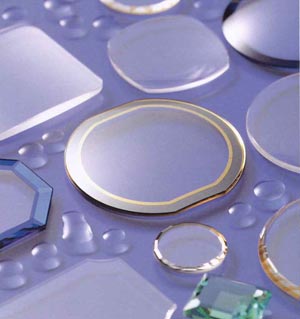

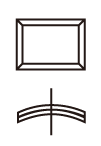

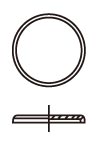

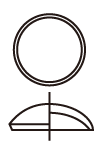

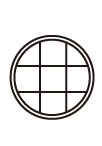

Shapes of sapphire cover glass

| Special shape sapphire | Cut sapphire | Flat sapphire | |||||

| Cylindrical | BOX | Dome | Knurled | 9-facet cut | 3-facet racer | Variant | Round |

|

|

|

|

|

|

|

|

| Has a delicate image made possible by a new polishing method | Jewel cut takes full advantage of sapphire's luxury | Utilizes sapphire's strength to achieve thinness | |||||

Even today, we as a watch component manufacturer have continued launching unique watch parts.