Durable non-contact optical connectors: Features and applications of Expanded beam connectors

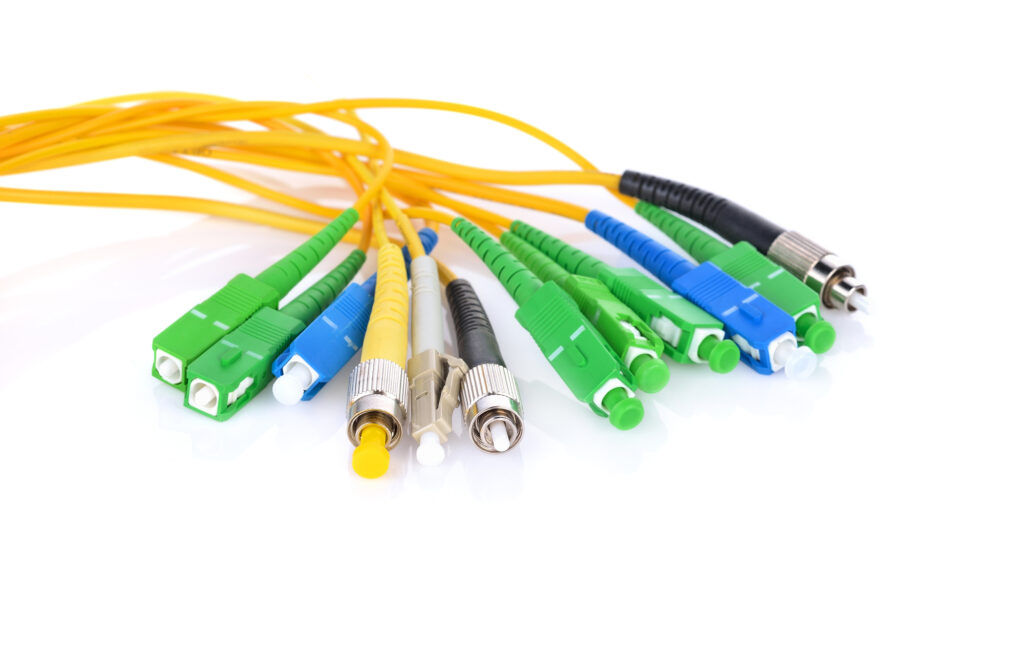

Recent years have seen significant evolution in data centers and other communications infrastructure with ever faster speeds and larger capacities. This has increased the need for stable and reliable optical connection technology that prevents light leakage. At the same time, demand for robust connectors that can withstand the harshest environmental conditions is also increasing. Compared to metal cables, fiber optics offer high-speed, large-capacity communication while remaining unaffected by external electromagnetic interference. However, fiber optics require expert handling, and optical connectors, in particular, demand specialized equipment and precise technology for proper connection and disconnection. For example, fiber optics connections are used in drone connectors, used in undersea exploration where radio waves cannot reach. Medical connectors require thorough disinfection and sterilization after each use. Expanded beam connectors offer greater durability, ease of handling, and superior reliability compared to conventional optical connectors.

This article provides basic information about expanded beam connectors, including their benefits and uses.

Table of contents [close]

- 1. Durable, non-contact expanded beam connectors, How are they different from other connectors?

- 2. Advantages of Expanded Beam Connectors

- 3. Applications of Expanded Beam Connections

- 4. Important points when selecting expanded beam connectors

- 5. Orbray's Optical Connector Technology

- 6. Summary of Expanded Beam Connectors

Durable, non-contact expanded beam connectors, How are they different from other connectors?

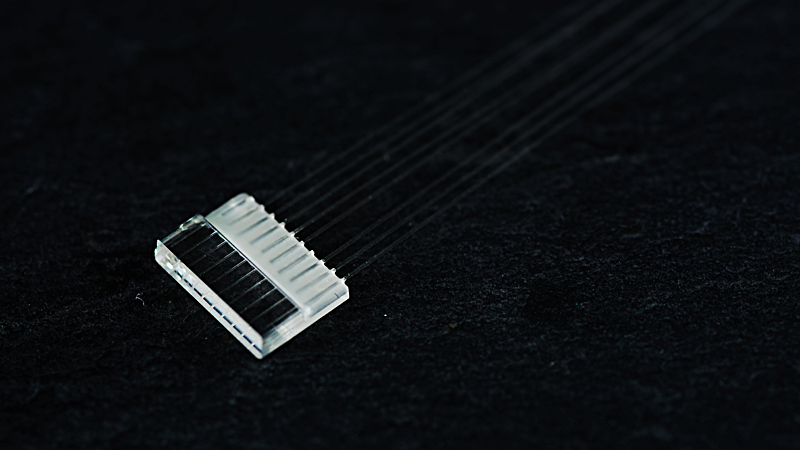

Expanded beam connectors couple light waves by expanding them using a lens at one end of the connector, refocusing them with a lens at the other end, and then returning them into the optical fiber.

Main components:

・Collimating lens

・Alignment mechanism

・Optical interface

In contrast, conventional optical connectors are joined directly by bringing the end faces of the fibers into direct physical contact with each other.

The direct contact between the fiber end faces in conventional connectors can cause loss of the transmitted data. Small amounts of dirt or other foreign matter known as contaminates, as well as scratches can significantly impede communication quality. Thus, polishing and cleaning the end face of the fiber when making connections requires specialized knowledge and handling.

However, expanded beam connectors do not require direct contact to make the optical connection. This avoids the issue of loss due to friction or contact. There is no degradation of the fiber end faces when connecting or disconnecting the connectors, eliminating the need for replacement or re-polishing. This makes them easier to handle without specialized optical fiber knowledge.

In addition, by expanding the light, the influence of contaminates is reduced, ensuring high reliability even in harsh environments where impurities are likely to enter.

For this reason, expanded beam connectors are suitable for applications where repeated insertion and removal occur, or for use in harsh environments where foreign objects are likely to enter.

For example, in aircraft and vehicles where parts need to be removed and replaced for maintenance, these connectors offer significant advantages. They do not deteriorate even with repeated plugging and unplugging and can be handled by mechanics without specialized knowledge of optical fibers.

Advantages of Expanded Beam Connectors

This section describes some advantages of expanded beam connectors compared to conventional optical connectors.

High Durability Against Foreign Substances

Expanded beam connectors are highly resistant to interference caused by contaminates or foreign substances such as dirt, dust, and mud.

Conventional optical connectors can experience reduced transmission quality if foreign matter gets between the end faces in contact, leading to issues like communication interruptions. However, expanded beam connectors are less affected by small amounts of foreign matter, reducing the risk of communication problems and ensuring high reliability.

For this reason, expanded beam connectors are ideal for use in harsh environments where foreign objects are likely to enter, such as outdoor settings or factories with high dust exposure.

No contact means no wear and tear

Expanded beam connectors use optical expansion to make connections without making physical contact. This eliminates deterioration caused by friction of the connector end face over time.

In optical connectors, friction occurs on the end surfaces that are in contact inside the connector every time a connection is made. Vibrations at the connection point, and forces applied to the cable also cause damage over time. Another problem is that insertion loss can fluctuate due to the rotation of the surfaces in contact. This can lead to issues such as communication interruptions and unstable connections over long periods of use.

Communication problems are particularly likely to occur when used with moving parts such as in machinery, aircraft, or vehicles, or in environments with vibrations. Expanded beam connectors avoid friction on the contact surfaces, so even after long-term use, there is no deterioration in communication quality due to friction, ensuring stable communication over the long-term.

Applications of Expanded Beam Connections

Expanded beam connectors are widely used in the aeronautics, aerospace, and military industries due to their resistance to foreign objects and vibrations, as well as their high reliability in harsh environments.

Currently, they are primarily used for specialized purposes, but have demonstrated their resistance to quality defects compared to conventional optical connectors. As a result, it is expected that they will become popular for more general applications in the future.

For example, the benefits of expanded beam connectors are also applicable to general passenger cars and machine tools, which are less expensive than aircraft and military connectors.

Modern cars are computer-controlled and use many communication cables internally. The use of expanded beam connectors for these connections is being considered.

Additionally, due to the minimal deterioration in communication quality, expanded beam connectors are highly effective in applications that require high reliability, such as medical equipment and data centers that handle important information.

Important points when selecting expanded beam connectors

Low insertion loss during connection and high communication quality after connection are the major points to be considered when selecting expanded beam connectors.

Expanded beam connectors are similar to conventional optical connectors in this respect. However, because expanded beam connectors use a non-contact connection method, they are slightly disadvantaged in terms of insertion loss compared to optical connectors. Additionally, the lenses at the ends that expand and focus the light require extremely fine processing technology.

Furthermore, to achieve a high-quality connection, the material of the ferrule, the component that precisely aligns the optical fiber and beam expander lens to produce a coaxial beam, is crucial. The physical properties of the ferrule significantly impacts the quality of the connection.

When selecting an expanded beam connector, it is necessary to understand these differences in quality, conduct actual insertion loss tests, and choose a product that ensures high communication quality.

Orbray's Optical Connector Technology

By leveraging high-precision processing technology cultivated over decades in the precision jewel industry, Orbray has been manufacturing optical fiber ferrules and sleeves for over 40 years,

All of our optical connectors use the highest quality zirconia ferrules, ensuring stable and reliable performance.

Additionally, the laser processing technology developed and researched by Orbray allows for fine and precise processing of the optical fiber ends. This results in extremely high-performance connectors with minimal loss fluctuation due to rotation.

⇒ Click here for more information about Orbray’s optical fiber connectors.

Summary of Expanded Beam Connectors

In this article, we explored some features and benefits of expanded beam connectors. Expanded beam connectors are highly durable and can be used for extended periods without the need for cleaning or worry of degradation due to harsh usage environments.

To learn more about Orbray’s optical connector technology, please visit our detailed explanation page.

-

“Physical Contact Push-Pull Technology for Fiber Optic Connectors” recognized as IEEE milestone. Promoting ferrules around the world through manufacturing.

-

What is an Optical Fiber Array? - Connecting devices with optical waveguide elements are indispensable for next-generation high-speed, large-capacity optical communications.

-

What are optical interconnects and fiber optics?

-

Multi-Core Fiber:The highly anticipated, next-generation high-speed communication technology

-

Award: Industrial Standardization Enterprise Award

-

What is a Ferrule? : The history and development of the ferrule continues today with its ever pursuit of high accuracy of 1um or less at reduced costs