Award: Industrial Standardization Enterprise Award

Orbray’s general manager of technology, Takashi Noshiro, received recognition on October 17, 2023, from the Director-General of the Industrial Technology and Environment Bureau of the Ministry of Economy, Trade and Industry for his many years of contributions to standardization as a member of the IEC (International Electrotechnical Commission)

Standardization involves setting standards for the dimensions, specifications, and evaluation methods of products. Imagine the chaos if every manufacturer created their own electrical plugs and outlets. Similarly, would you confidently purchase a product without knowing the manufacturing conditions of the factory that produced it? In our global economy, where a single product often comprises components from several different countries, nations worldwide are engaging in standardization across all types of products.

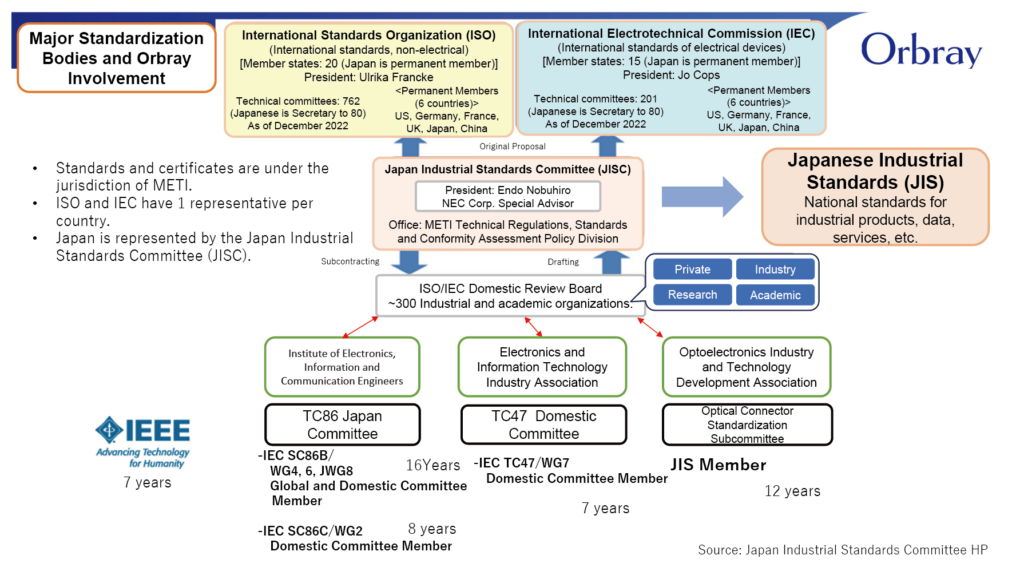

There are numerous organizations that promote standardization, including the International Organization for Standardization (ISO), which addresses a broad range of fields. The IEC focuses on standardization of electrical products. In Japan, these are represented by the Japan Industrial Standards Committee (JISC), formed by the Ministry of Economy, Trade and Industry (METI). JISC membership is comprised of around 300 industry associations and academic societies. In Japan, these fields are subdivided into hundreds of categories, with experts industriously deliberating standards in each field.

Being a member of an organization that aligns the interests of global manufacturers and sets international standards is an honor for any company. Additionally, leading the charge in promoting standardization offers a unique opportunity to access information across a broad spectrum of fields. This rewarding role can pave the way for the development of new products.

While Europe and the United States frequently lead standardization efforts globally, Nippon Telegraph and Telephone Corporation (NTT) has lead the way in the field of optical communications.

Currently, Orbray has five committee members contributing to standardization, both in Japan and globally. Noshiro was honored for his 16-year tenure with the IEC. During this period, he made contributions as an expert in three notable conferences. He proposed innovative methods for measuring angular misalignment between the ferrule bore axis and the ferrule axes, concentricity, and withdrawal force in cylindrical all-zirconia ferrules and zirconia split sleeves, which were invented in Japan and are crucial for high-accuracy optical fiber connections. Beyond participating in committee discussions and serving as a project leader in the revision of standards, he took leadership roles in many of his activities.

When a field is identified as needing standardization, the proposer or a committee member associated with the field is often appointed as a project leader. This role involves challenging tasks such as providing experimental data and preparing extensive materials in English. Writing these documents is quite difficult, and there's even a specific rulebook, known as the “ISO/IEC Directives” for creating standards. The project leader distributes the documents to committee members via the IEC central office. In response, delegate from various countries may offer feedback, suggesting changes or raising queries, and the leader must address each comment meticulously. With dozens of such comments collected, the committee convenes twice a year to review and resolve issues. These meetings, hosted by one of the participating countries, are critical for addressing each point of contention. A standard undergoes six stages before publication. With only two meetings per year, the process takes a minimum of three years, but can sometimes take as long as six years.

Regarding the standardization of optical connectors, amendments to existing standards have been more common than the creation of entirely new standards. NTT instigated the development of Orbray's key products, such as the cylindrical all-zirconia ferrule and zirconia split sleeve. Orbray, in collaboration with several other Japanese companies, has played a significant role in supporting the standardization of these products through the JIS. Subsequently, we presented our findings to the IEC sub-committee, with Noshiro leading efforts to gain global acceptance for standards surrounding these innovations. Additionally, Orbray is actively involved in incorporating international standards set by the IEC into the JIS framework.

Upon receiving the award, Noshiro remarked, "It is a great honor, but I must acknowledge the hard work of our industry's predecessors who laid the groundwork for standardization. I have merely inherited their accomplishments. This achievement would not have been possible without the cooperation of every committee member."

-

The Importance of Chip Mounter Nozzles

-

100 times faster than 5G! What is possible with 6G?

-

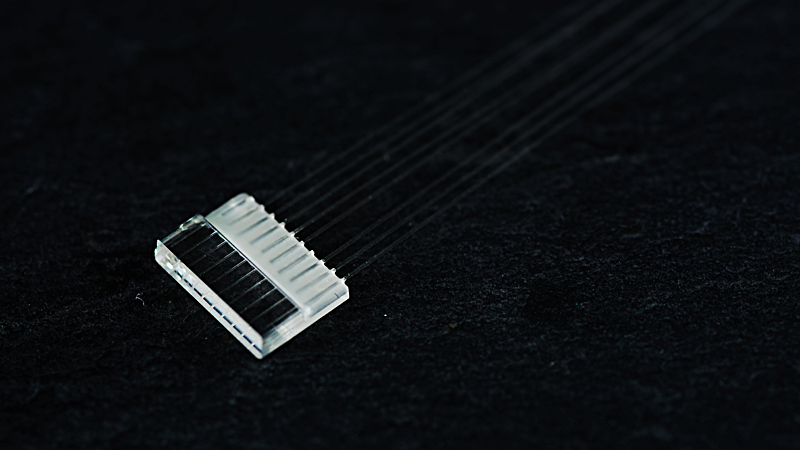

What is an Optical Fiber Array? - Connecting devices with optical waveguide elements are indispensable for next-generation high-speed, large-capacity optical communications.

-

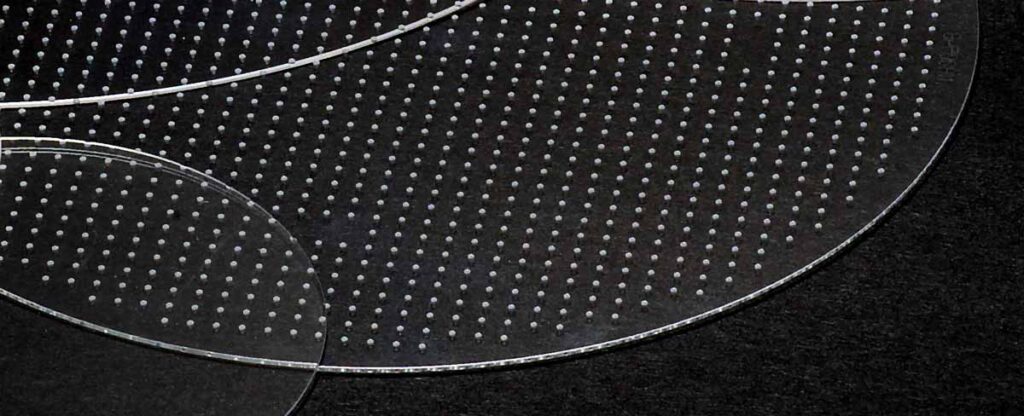

Surface polishing technologies - Essential technologies for semiconductor, MEMS, and LED manufacturing

-

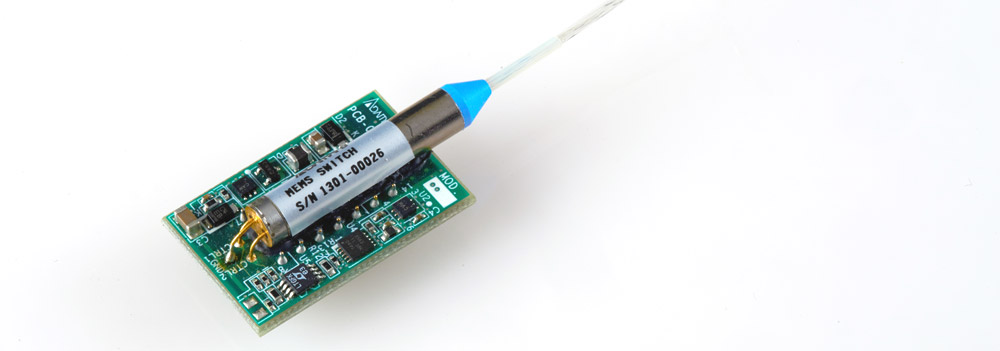

Optical Switches and their significance in High-speed, Large-Capacity Optical Communications

-

Cleavage of Jewel