Introducing Bioceramics: Challenges, features, and applications

Bioceramics is a type of biomaterial that is expected to play an important role in the advancement of the medical field. This article explains some of the current challenges that must be overcome by bioceramics, and the features and applications of Orbray’s bioceramic materials for those who are interested in using bioceramics or developing new products using this innovative material.

Table of contents [close]

What are bioceramics?

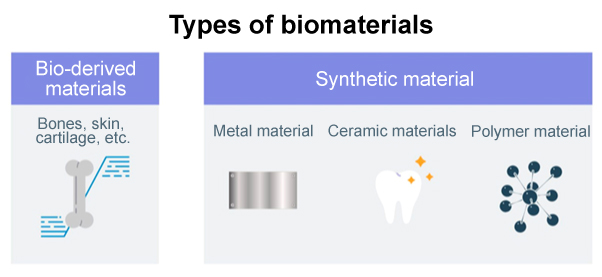

Synthetic biomaterials can be made of metals, polymers, or ceramics.

Metals have high strength and toughness, and are very difficult to break. However, they are subject to fatigue and corrosion. Polymers are lightweight, flexible, and easy to process into useful shapes, but are inferior to other materials in terms of strength and impact resistance.

Calcium phosphate ceramics are made of phosphate ions and calcium ions. This is very similar to an inorganic substance called hydroxyapatite, the primary component of human bones and teeth.

Consequently, ceramic materials, known for their high strength and biocompatibility, are extensively used not only in dentistry but also in the creation of artificial bones and joints. Demand for these materials is increasing as people around the world are enjoying longer, healthier lives. When used in conjunction with the tissues of living organisms, these ceramic materials are referred to as bioceramics or ceramic biomaterials.

Challenges facing conventional bioceramics

Materials used to make artificial bones must be biocompatible. They also need to function similarly to bone. Hydroxyapatite is a calcium phosphate ceramic with composition similar to bone and other special properties that allow it to bond directly to bone.

However, it has low strength and is difficult to process into precise shapes, limiting its applications. Therefore, there is a need for bioceramics that can bond well with bone and maintain the strength of bone.

Introducing a new bioceramic: Bio-Zirconia

Zirconia has four to ten times the mechanical strength of hydroxyapatite, making it ideal for use in artificial bones. It also has much better heat resistance, chemical durability, and biocompatibility. Frequently used in dental implants, zirconia is an ideal material because it doesn't easily release ions like metals, is hygienically safe, and has an aesthetically pleasing appearance. Its resistance to wear also makes it suitable for use in knee and hip joint bones, demonstrating its reliability in clinical settings.

To utilize the positive characteristics of both materials, Orbray has developed a new material called Bio-Zirconia. It uses zirconia as a base material, taking advantage of its excellent strength and workability, and adds bioactivity through the incorporation of hydroxyapatite to the surface. The details of this innovative product will be explained in the rest of this article.

Proprietary process gives bioactivity to Bio-Zirconia

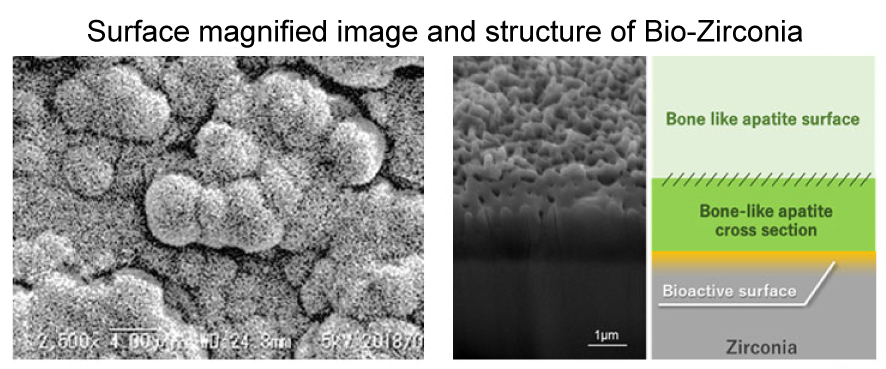

Common challenges in surface modification technology involve issues such as peeling due to insufficient bonding strength between the surface layer and the base material. However, Bio-Zirconia is produced through a specialized process designed to enhance the adhesion between the 0.5 µm thick hydroxyapatite surface layer and the zirconia base material, effectively eliminating these concerns.

In the surface modification process for Bio-Zirconia, a slurry of fine hydroxyapatite particles measuring 1 µm or less dispersed in water is prepared. This mixture is then applied to the zirconia base material, which has been preheated to 1050℃ to improve its wettability. This establishes the optimal conditions to ensure uniform adherence of the slurry to the zirconia surface.

As a result, a layer of hydroxyapatite, which is biologically very similar to bone, is uniformly formed on the surface of the zirconia, with very strong resistance to peeling. Following this, the zirconia is dried at temperatures ranging from 100℃ to 500℃ and then baked at high temperatures. This creates a molten mixture between the hydroxyapatite and the zirconia base material. Unprecedented adhesion is achieved, a result unattainable with conventional techniques.

Because of these properties, the newly developed zirconia material, Bio-Zirconia, can be effectively used as a bio reinforcement material.

Future prospects and applications of Bio-Zirconia

Zirconia is a material that is well-suited for use in living organisms. It has frequently been used in dental applications and as a component in the sliding parts of artificial bones. However, its application has been limited to these uses, due to its inability to chemically bond directly with bone. Bio-Zirconia, with its enhanced bioactivity, extends the potential of zirconia, making it a more versatile biomaterial, suitable for a broader range of applications.

For example, joint implant devices used to treat osteoarthritis and rheumatoid arthritis of the hip, and femoral head necrosis are subject to loads that exceed body weight and must withstand even larger loads and shocks during exercise. To cope with these loads, different materials have traditionally been used for the head and the stem of the femur.

By implanting Bio-Zirconia that has undergone surface modification in only the necessary areas, it is believed that the implant will rapidly integrate with the surrounding bones and tissues, and that such integration will enhance the structural stability and strength of the artificial joints, making them capable of supporting high loads.

In these ways, Bio-Zirconia is expected to be a complete substitute for living bone, which has complex structures and properties.

-

All About Lasers: How they work, their properties, and their uses

-

Pioneering the Future of Multi-Core Optical Fiber Connections : Orbray's Optical Fiber Bundling and Light-Induced Self-Written Optical Waveguide Technology

-

Introduction to winding nozzles: an essential component of the motor coil winding process

-

Introduction to suction nozzles and collets

-

What is a Ferrule? : The history and development of the ferrule continues today with its ever pursuit of high accuracy of 1um or less at reduced costs

-

High Flatness Polishing Processing