Principal of Cylinder Phonograph, Sound Groove and Stylus Tip

Table of contents [close]

Though it was high-pitched and hysterical sound, they heard clear reproducing sound from the phonograph which resembles a machining tool

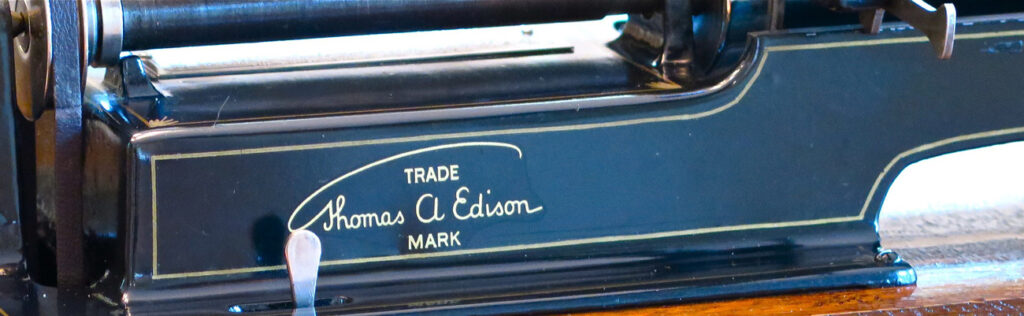

He succeeded in picking up and recording ‘sound’ that dies away instantly. The humankind’s first recording was “Mary had a little Lamb” sung by the phonograph’s inventor, Edison. A sound dies away in no time. Thomas Edison, who succeeded to store up this sound for the first time in history.

Edison got a cue how to record and reproduce a sound while working on a telephone. A genius inventor, Edison, who didn’t take 5 min. to materialize the idea and passed the drawing onto plant manager, Kruesi who didn’t know what it was for, to build, but supposedly did within 30 hours, he made the first cylinder phonograph.

Edison explained his workers the phonograph “a device for recording and reproducing sound”. “Ridiculous” they shouted and bet director’s cigar.

After all, Edison won this bet. Edison recorded his voice to the diaphragm loudly, shouting rather than singing. “Hello, hello, Mary had a little Lamb!”

The machine played his words back to him. The sound was high-pitched one, though. It was late autumn in 1877.

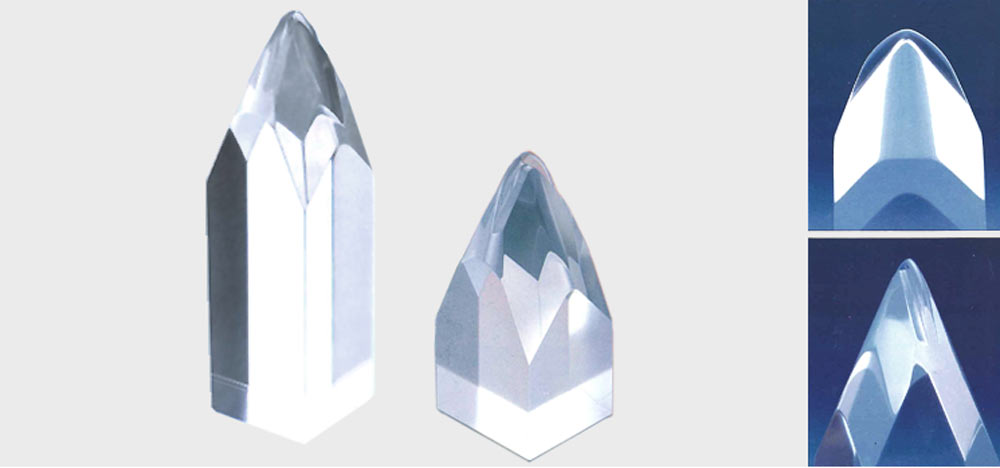

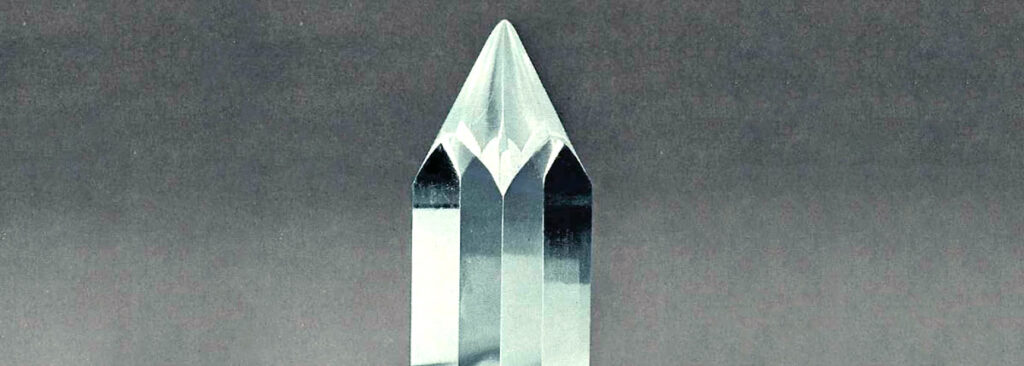

Principal of Cylinder Phonograph, Sound Groove and Stylus Tip

Let’s review the principal of cylinder phonograph, sound groove and stylus tip.

Edison began experimenting with the diaphragm of a telephone receiver by attaching a needle to it. The tinfoil was wrapped around a groove metal cylinder and a sound-vibrated stylus indented the tinfoil while the cylinder was rotated. When you spoke into the mouthpiece,

the sound vibrations of your voice would be indented onto the cylinder by the recording needle this cylinder phonograph was the first machine that could record and reproduce sound created a sensation.

Edison developed a greatly improved Phonograph later that employed hollow wax cylinder instead of a foil sheet.

Let’s talk about a stylus tip. It was an iron in material at first.

There was a significant problem, it was that no mass method of duplicating cylinders existed. It’s required very painful work day after day to make a production of hollow wax cylinder which had difficulties in making a duplicate.

In order to make it, either performers had to repeat their performances or letting a bunch of phonograph operate at a time when recording. In short, mother disc, which was made direct-cut as we call now, was the commodity.

It’s said that production capability was about 300 – 500 pcs a day in 1890s. Even if there were 10 of phonograph machines, you had to play the same song simply 40 times to make 400 pcs of hollow wax cylinders.

The explanation of the record needle is also available on this page.

Stylus Tip