Small Servo Motor for Robot Joints

Table of contents [close]

Small Servo motors for robots extending from communication robots to industrial applications

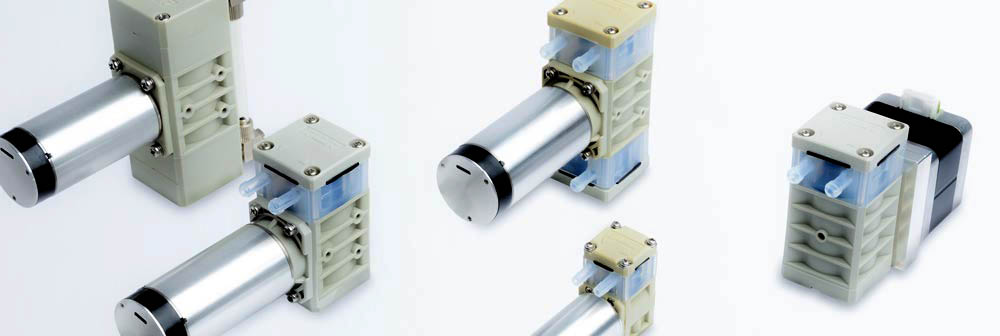

The industry's smallest servo motor for robot articulation, 12 mm x 24 mm x 12 mm, has expanded the potential for consumer electronics and industrial robots.

Orbray and Sharp jointly developed this small servo motor, and Sharp launched it in 2016 as part of RoBoHoN, a mobile robot phone.

This small, lightweight, brushless motor and non-contact position control have made it possible to extend the product’s life span, and led to the development of a collaborative robotic hand called K3HAND, which will be used as a next-generation product to compensate for labor shortages in the industrial and inspection/medical fields.

“I want to create a little robot companion that fits in my pocket!”

Our company’s entry into robot joint small servo motors began in November 2013, when Sharp approached us about the development of a new type of smartphone. The aim was to develop a robot phone designed by robot creator Tomotaka Takahashi.

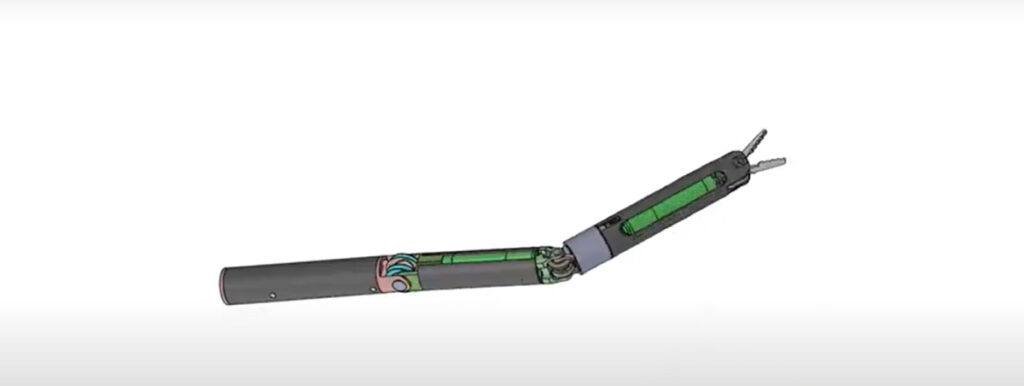

The vision: A robot companion that fits in one’s pocket. At the time, most of the existing small servo motors for small robots were for toys, and there was no product with a performance that met the durability and quietness required for home appliances. As such, we were called upon based on our track record in developing small servo motors. Since the project application was small robots, we developed our own drive mechanisms, such as gears and clutches. Sharp, which specializes in phones, was in charge of designing the thin circuit board necessary for the mobile phone, while the small servos were completed together using our companies’ collective strengths.

A brushless motor was used for the servos to increase durability by more than 500 hours. In order to maintain the nature of the design, the servo part was given an arched shape. We also developed a clutch that slides the gear to prevent damage from external loads.It has grown into a long-run product.

Successive adoptions in communication robots

With the birth of RoBoHoN, the equipped small servo motors also attracted attention, leading to successive adoptions of our motors in other projects. First, we were approached by Sony regarding their pet-type robot, "aibo". A motor was newly developed in response to the unprecedented demands for small size, high torque, and long life. We proposed a 4-pole magnet-equipped motor. Its quietness and quick response were highly appraised, and it was adopted for use. The specifications were decided in 2017, and we were able to commercialize it in 2018.

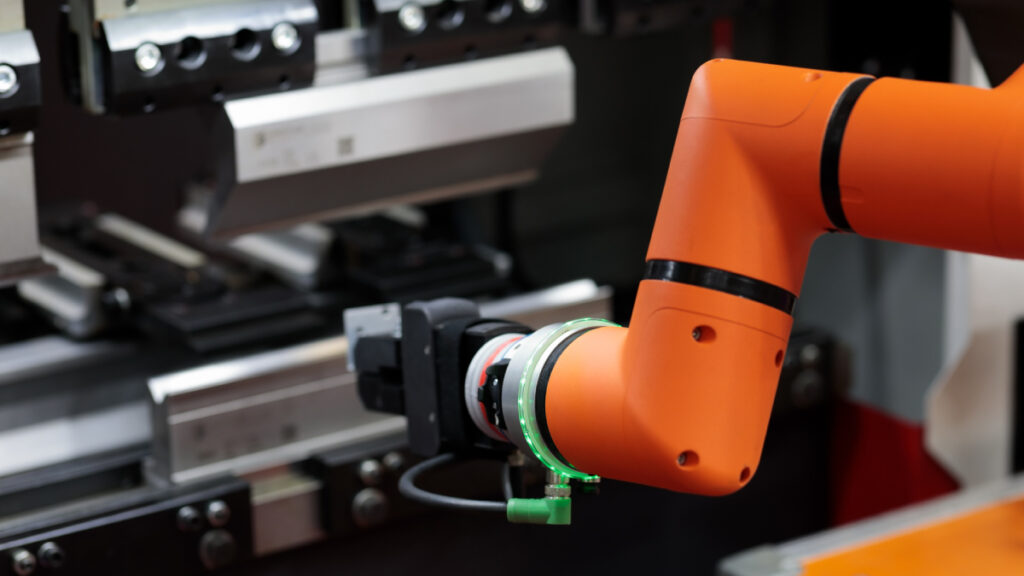

This trend in motor use has begun to be applied not only for communication robots, but also for industrial robots, and is expected to be introduced for the joints of collaborative robots that work together with humans, and potentially utilized for future humanoid robots as well.

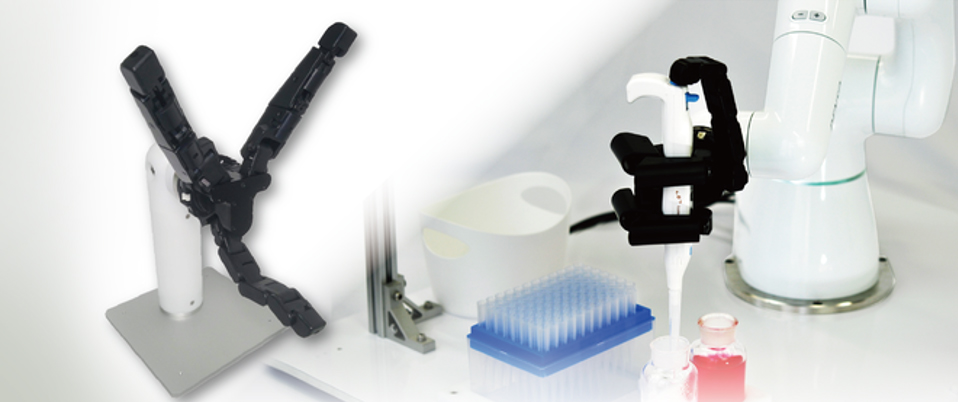

Becoming an industrial hand manufacturer

We are currently evolving from the development of small servo motors for robots to the next stage. In 2018, we started developing our own robotic hand that uses a combination of parts such as servos and gears to move its fingers.In 2020, we completed this three-fingered “K3HAND”, which can be mounted on the end of industrial robots. Its name, K3, comes from its three main attributes: “Kiyou” (dexterity), “Kogata” (small size), and “Keiryou” (light weight). Equipped with eight small servo motors with eight axes, it is characterized by its ability to move and operate in a manner similar to that of human fingers. It can be mounted on multi-axis, double-arm, and other various robots. As a recent example, we have been investigating the potential for the hand to be used in combination with a multi-axis robot for coronavirus testing, or with a double-armed robot as a remote operation system to work in environments that humans can’t or shouldn’t be near. From here on, we intend to strengthen our development as an industrial robotic hand manufacturer.

More information about the small servo motor :