Wood Boiler "DanZO" Significantly Reduces Oil Consumption by Burning Wood Scraps and Forest Waste

Kuroishi Factory General Affairs Dept.

The government has set a goal of carbon neutrality, aiming to reduce greenhouse gas emissions to zero by 2050. As part of various initiatives Orbray is undertaking toward this goal, the company has implemented a new project at its Kuroishi factory in Aomori: using wood scraps and tree branches to heat water that is then circulated to heat a building. This involves the introduction of a US-made boiler called the DanZO.

Wood is internationally recognized as carbon neutral by organizations such as the Carbon Disclosure Project (CDP). This is because trees absorb carbon dioxide (CO2) during their growth process, which balances out the CO2 released when they burn. This will contribute to Orbray's carbon neutrality goals for 2050.

This initiative is not just for preventing global warming. The significant price increases in gasoline and kerosene due to the weak yen and rising crude oil prices caused by overseas conflicts are threatening our lives. From January, government subsidies that have been keeping gasoline and kerosene prices down will be gradually reduced, leading to expectations for further price increases. Diversifying energy sources offers multiple benefits for Japan's future.

Additionally, for Orbray, which operates businesses globally, addressing sustainability throughout the entire supply chain is a crucial issue. The DanZO project may attract attention from international organizations that evaluate environmentally and socially responsible business activities, making it an attractive initiative in this respect as well. Particularly in recent years, a company’s sustainability stance has become an important factor in building relationships with business partners globally, and Orbray hopes to take a step toward better evaluation through this project.

While Aomori and Akita, where Orbray has production bases, are rich in forest resources, there are many hurdles to overcome for effective utilization, and progress has been slow. The DanZO was chosen as a heating source because it is environmentally friendly and can utilize previously unused local resources.

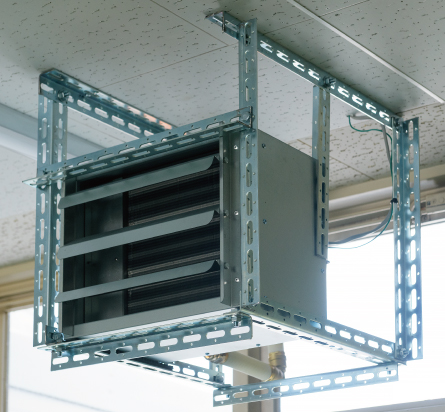

The DanZO is a rectangular device slightly larger than a public telephone booth. In the United States, it is used in ordinary homes in remote areas where oil delivery and gas services are unavailable. In Japan, apart from the Central Timber Wholesale Market in Akita City, where it was introduced for demonstration purposes, the Kuroishi factory is the first to adopt it.

At the Kuroishi factory, where the average winter temperature is 6-7℃ lower than in the Kanto region, electric heat-exchanger air conditioners alone are insufficient, so oil heaters have been used to heat the employee cafeteria, changing rooms, and one 100-meter long factory building. The DanZO is intended to replace these oil heaters.

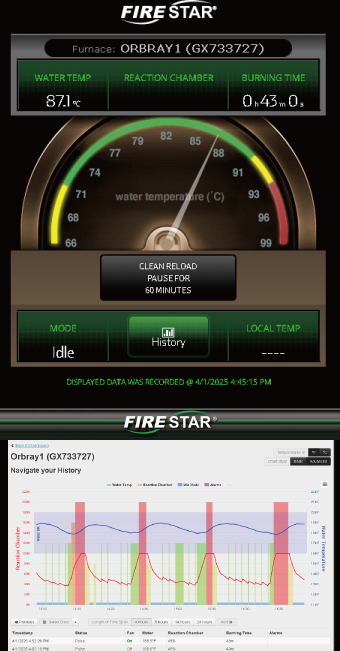

The DanZO is quite high tech. It measures the temperature inside the furnace and the water with sensors, which can be checked via smartphone or computer. It automatically adjusts the burning method using gas generated from the wood, so it doesn't require constant supervision. It also has very high combustion efficiency, burning over 90% of the wood and leaving only ash, eliminating concerns about soot accumulation or chimney blockage that are common with wood stoves.

Another advantage is that the DanZO doesn't require a dedicated building or equipment for drying fuel wood; it only needs pipes to circulate the heated water within the building, keeping costs low.

The DanZO's ability to burn any type of wood is also appealing. It can generate heat from all kinds of wood, including unused wood, trees and branches from the thinning of forests, low-quality materials, and wood scraps. Although it was said that drying the wood before burning didn’t matter, in practice, this wasn't entirely true. The firewood prepared for this year will be dried for a year for next year's use, and for this year, we have purchased firewood that had been dried for a year.

The DanZO arrived in Kuroishi in mid-February. After connecting the necessary pipes to circulate the hot water and making some adjustments, it is now working well.

According to our calculations, Orbray expects to reduce CO2 emissions by 110 tons annually and save 30,000 liters of kerosene through the introduction of the DanZO. Due to recent kerosene price increases, using firewood costs only one-third compared to oil.

In Japan, 8 million tons of wood from the thinning of forests are wasted annually. This represents the energy equivalent to 12 billion liters of kerosene, far exceeding the amount of kerosene consumed by households nationwide.

Effectively using wood that would otherwise be discarded aligns with SDG Goal 12. In the American movie "Back to the Future II," the DeLorean car used as a time machine used garbage as fuel. The DanZO, which is a small boiler that heats buildings by effectively utilizing wood previously considered worthless, embodies a similar dream.

One challenge is the need to load 30 kilograms of firewood every three hours. While placing the boiler outdoors is cost-effective, it means having to go outside even in snowstorms to transport firewood from a slightly distant warehouse by car. However, the team is motivated to enjoy the firewood transportation process, knowing they are contributing to reducing the company's overall environmental impact and experiencing the satisfaction of using clean wood energy instead of fossil fuels like oil.

Please click below to check SDGs activities by Orbray Co., Ltd.