Sintering Trays and Setter Plates

Sintering trays and setter plates, also called sintering setters, are jigs that are used as the base when sintering electronic components in a furnace.

Furnace temperatures can exceed 1,000℃ during the sintering process. If the materials being sintered come into direct contact with the furnace floor, they may become deformed or stick. Sintering trays and setter plates are used to avoid these issues by supporting the components and increasing their stability within the furnace.

To improve the dimensional accuracy of the components, temperatures within each component should remain uniform. Sintering trays and setter plates with high thermal conductivity can help reduce temperature variations, thereby improving yield and productivity.

Furthermore, sintering trays and setter plates must be highly chemically stable so that they do not interact with the product itself and introduce impurities that could negatively impact product quality and consistency.

The various properties of sintering trays and setter plates allow their use in a wide range of applications, some of which are outlined below:

- * Sintering electronic components such as capacitors and resistors

- * Sintering ceramics and industrial ceramics

- * Powder metallurgy: molding and sintering metal powders

- * Sintering fuel cells and electroceramics

Table of contents [close]

- 1. Types of Sintering Trays and Setter Plates

- 2. Advantages of Sapphire

- 2.1. Exceptional dimensional stability in high-temperature conditions

- 2.2. Chemically stable, no matter the conditions

- 2.3. Thermal conductivity, essential to quality

- 2.4. Outstanding mechanical properties that withstand repeated use

- 2.5. Smoothness is cleanliness

- 2.6. Achieving economic value through durability

- 3. Summary

- 4. Related products

Types of Sintering Trays and Setter Plates

Setters made from a wide range of materials are used in the manufacturing of electronic components. Materials are selected based on the application and budget, taking advantage of the unique characteristics of each material.

Alumina Setters

Alumina is the most commonly used material for sintering trays and setter plates. For sintering general electronic components, high-purity alumina (99.5% or higher) provides great cost performance. Alumina setters are heat resistant up to 1,700℃, making them appropriate for most sintering processes. They are also easily available, and initial investment requirements are low. Mullite-based alumina has high resistance to thermal shock and provides consistent performance even in processes with drastic changes in temperature.

Zirconia Setters

When higher performance than alumina setters is required, zirconia is used. Yttrium-stabilized zirconia (YSZ) provides high thermal shock resistance and can withstand sudden temperature changes. It also has high mechanical strength and resists deformation. When supporting heavy components or high mechanical loads where even greater strength is required, partially stabilized zirconia (PSZ) is used.

Silicon Carbide (SiC) Setters

The most important characteristic of silicon carbide setters is their high thermal conductivity. Reaction-bonded SiC offers exceptional thermal conductivity, providing uniform temperature distribution, leading to improved sintering quality. SiC setters can also be used in special firing conditions such as reduction environments. Sintered SiC, with its high density and excellent mechanical strength, is ideal for applications requiring precise dimensional control.

Silicon Nitride (Si₃N₄) Setters

Silicon nitride setters provide great thermal shock resistance with high-temperature strength. They are highly resistant to sudden temperature changes, and maintain consistent performance even during drastic temperature cycles. Their mechanical strength is maintained at high temperatures, reducing the risk of deformation or failure during sintering.

Sapphire Setters

Sapphire offers the highest level of performance in sintering applications. With an extremely high melting point of 2,040℃, they offer outstanding chemical stability and mechanical strength.

Advantages of Sapphire

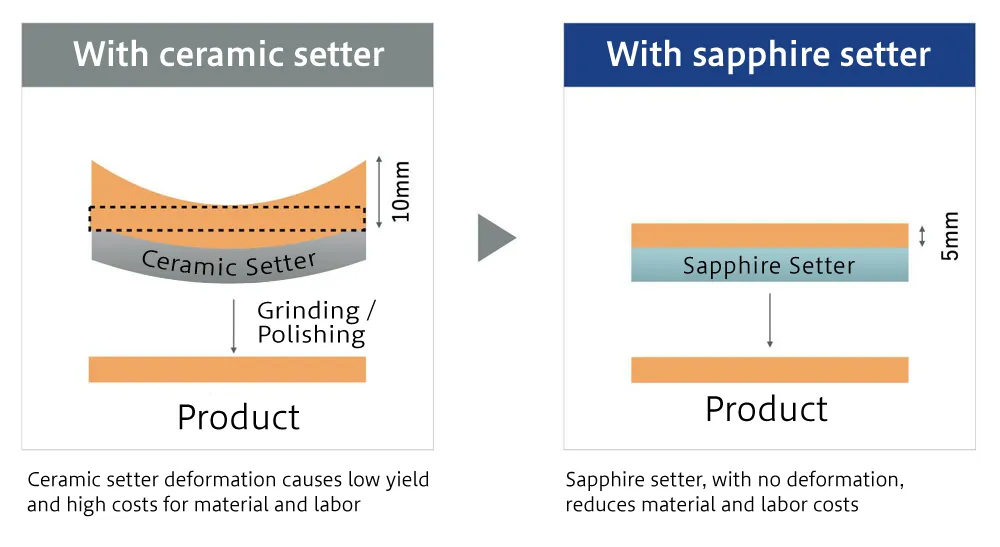

Exceptional dimensional stability in high-temperature conditions

With a melting point of 2,040℃, unmatched by ceramic materials, sapphire maintains its shape accurately in high-temperature processes exceeding 1,800℃. Its thermal expansion coefficient is also very low, minimizing changes in dimensions caused by temperature fluctuations.

Chemically stable, no matter the conditions

Sapphire is highly inert in both oxidation and reduction environments, minimizing the risk of contamination of the sintered products. This makes sapphire especially suited for use in electronics manufacturing processes that demand high purity.

Thermal conductivity, essential to quality

The high thermal conductivity of sapphire ensures uniform temperature distribution, contributing to consistent quality of sintered products.

Outstanding mechanical properties that withstand repeated use

Sapphire’s high hardness and excellent mechanical strength resist deformation and wear over long periods of use, contributing to stable production quality.

Smoothness is cleanliness

The smoothly finished surface of sapphire minimizes adhesion and reactions with the end product during sintering, contributing to a clean sintering environment over the long term.

Achieving economic value through durability

Although initial investment is comparatively high, sapphire’s exceptional durability allows for use over a long period of time. That coupled with proper maintenance offers attractive cost performance over the long term.

Summary

The various types of sintering trays and setter plates offer distinct advantages that are suited for specific applications. For processes that require high temperatures, high purity, and chemical inertness, or consistent performance over time, sapphire setters offer many beneficial qualities that can contribute to improving both product quality and production efficiency.