Diamond applications in the space industry

Diamonds, often referred to as the king of gems for their beauty and rarity, are widely known for their use in jewelry. However, beyond the aesthetic appeal of diamond gemstones, diamond as a high-performance material plays a crucial role in various important scientific and industrial applications.

In this article, we explore the unique properties of industrial diamond and highlight an example of its innovative use in the space industry.

Table of contents [close]

Requirements for use in space

The performance requirements for materials and equipment to be used in the space industry vary depending on the application, but one essential factor is common to all: components used in space must be exceedingly durable and able to withstand the extreme conditions found in outer space.

One of the most severe challenges is temperature. Unlike on Earth, where the atmosphere stabilizes temperatures by allowing heat to transfer through convection, space is a vacuum, meaning there is no air to distribute heat. As a result, rockets and artificial satellites orbiting Earth experience extreme temperature fluctuations, reaching as low as -150°C in the shade and soaring to +120°C in direct sunlight.

Earth’s atmosphere protects us from the many dangers of the cosmos. However, in outer space radiation (high-energy particles and electromagnetic waves) has serious negative effects on the human body and electric devices installed on board spacecraft.

Furthermore, once a spacecraft is launched into space, repairs become highly restricted. Therefore, thorough quality control and reliability are required so that it can operate stably even in such harsh environments.

Characteristics of diamond that make it indispensable in the space industry

Diamond has several important properties that make it invaluable in the space industry. It is exceptionally strong due to its unique atomic structure, in which carbon atoms are arranged in a regular tetrahedral pattern and bonded by strong covalent bonds. This structure not only gives diamond its remarkable hardness but also provides a range of unique properties that make diamond ideal for use in extreme environments like space.

High thermal conductivity

Diamond is one of the most efficient materials for heat transmission. Its thermal conductivity coefficient, which measures how easily heat is transferred, is 2000 W/m·K—about five times that of copper, a metal known for its excellent thermal conductivity.

In general, materials that do not conduct electricity have lower thermal conductivity than metals. However, diamond stands out in this regard due to its extremely strong covalent bonded carbon atoms. Heat is transmitted through these bonds as vibrations, resulting in exceptionally high thermal conductivity compared to other electrically insulating materials.

Resistance to high temperatures

Diamond exhibits exceptional heat resistance due to the strong covalent bonds between its carbon atoms. On Earth, due to the presence of oxygen in our atmosphere, graphitization of diamond begins at around 600°C. However, in the oxygen-free environment of space, diamond can withstand temperatures of up to 1400°C, making it highly durable in extreme temperatures.

Excellent material for use in semiconductor devices

Recently, diamond has been gaining attention as a material for the next generation of power semiconductor devices due to its outstanding performance. Power semiconductors are used to convert power through switching operations, requiring characteristics such as a high maximum voltage tolerance, fast switching speed, and high heat resistance.

Diamond surpasses conventional semiconductor materials like silicon, silicon carbide, and gallium nitride in key properties such as band gap, dielectric breakdown field strength, carrier mobility, and dielectric constant. These characteristics make it a promising material for achieving higher output, faster operation, and stable performance in high-temperature and high-voltage environments.

Resistance to radiation

Radiation transfers energy as it passes through a material, knocking electrons loose and causing ionization. Diamond, with its strong carbon-carbon bonds and high electron affinity, exhibits exceptional resistance to radiation—about 1,000 times greater than silicon, which is commonly used in semiconductor devices.

This remarkable resistance to radiation makes diamond not only suitable for use in outer space but also ideal for extreme radiation environments, such as inside nuclear reactor containment vessels.

Other properties

Beyond the characteristics mentioned above, diamond possesses several other remarkable properties. With a Vickers hardness of approximately 10,000 Hv, diamond is known as the hardest material on Earth. It is about five times harder than carbide, a material widely used in making high-hardness tools.

This extreme hardness makes diamond an ideal material for cutting tools. Additionally, due to its wide band gap, diamond can transmit high-energy ultraviolet light without absorption, providing high transmittance across a broad wavelength range from ultraviolet to infrared.

Diamond applications in space

Next, we will explore specific examples of how diamond is utilized in the space industry.

Material for semiconductors

A spacecraft’s limited space and electric power available for equipment require compact and highly efficient semiconductor devices. Diamond semiconductors, with their exceptional performance and high radiation resistance, offer significant potential for use in the space industry.

Research on diamond semiconductors is being conducted by space agencies worldwide. In Japan, a project has been launched to test their functionality in outer space, specifically as a component for space communications.

Material for optical windows

Diamond was used as the window material for the infrared observation equipment on the Venus probe Pioneer Venus. The probe carried numerous scientific instruments to study Venus’s clouds, atmosphere, and solar wind particles. It successfully conducted long-term atmospheric observations from 1978 to 1992.

As the second planet from the Sun, Venus has extreme surface temperatures exceeding 400°C, requiring special heat protection for onboard analysis equipment. With its exceptional heat resistance and high transmittance properties, diamond was chosen as the ideal window material.

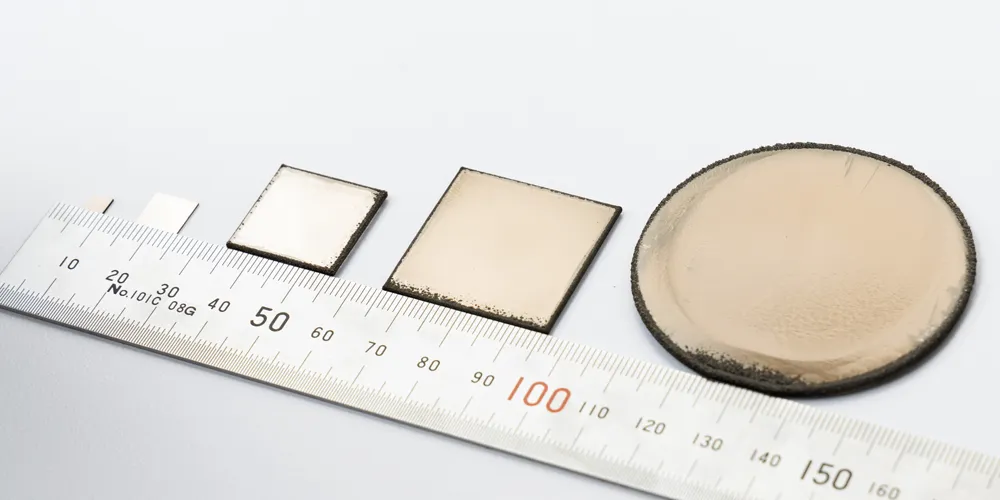

A diamond window with a diameter of 18.2 mm, a thickness of 2.8 mm, and a weight of 13.5 carats was used as the actual window for the probe, ensuring durability and optimal infrared observation.

Heat spreader

Space is a vacuum. There is no air for heat transfer or convection to occur. Heat is transferred by infrared radiation. However, equipment must not get too cold. At the same time, heat generated by the equipment must be efficiently dispersed.

Due to its exceptionally high thermal conductivity, diamond is used to rapidly distribute heat and prevent localized overheating.

Other applications

The very high hardness and wear resistance of diamond make it an optimal material for use in cutting tools used in the space industry. One important application is the manufacture of telescopes.

Satellites observing Earth, as well as satellite and ground-based observatories studying deep space, require large, high-precision telescopes to capture distant objects with perfect clarity. Diamond tools are used in the fabrication of telescope mirrors, ensuring precise cutting and shaping of the material. For example, diamond cutting tools were used in the processing of the mirrors for the Subaru Telescope, a large optical-infrared telescope located in Hawaii.

In addition to telescope manufacturing, diamond tools are also widely used in the processing of carbon fiber reinforced plastics (CFRP), a key structural material for satellites. Due to its light weight, high strength, and rigidity, CFRP is extensively used in spacecraft construction, but it wears down conventional cutting tools quickly. Diamond tools are therefore used for machining this material.

Summary

This article introduced the properties of diamond that make it invaluable for components used in the space industry, and highlighted some examples of applications.

With its high thermal conductivity, exceptional temperature and radiation resistance, and outstanding semiconductor performance, diamond has already found applications in outer space, where it endures the extreme conditions. As research and technology advance, the use of diamond in space-related industries is expected to grow even further.

Orbray has established a comprehensive manufacturing system for diamond and industrial jewel components, covering everything from material development to precision processing.

For inquiries regarding Orbray’s diamond and industrial jewel components, please contact us at ….